Industrial production method of semi-crystalline poly aryl ether nitrile

A polyarylene ether ether nitrile technology and a production method, which are applied in the field of polymer materials, can solve the problems of high price, low modulus, strength and heat resistance, and achieve the advantages of low cost, easy realization of production conditions and centralized processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

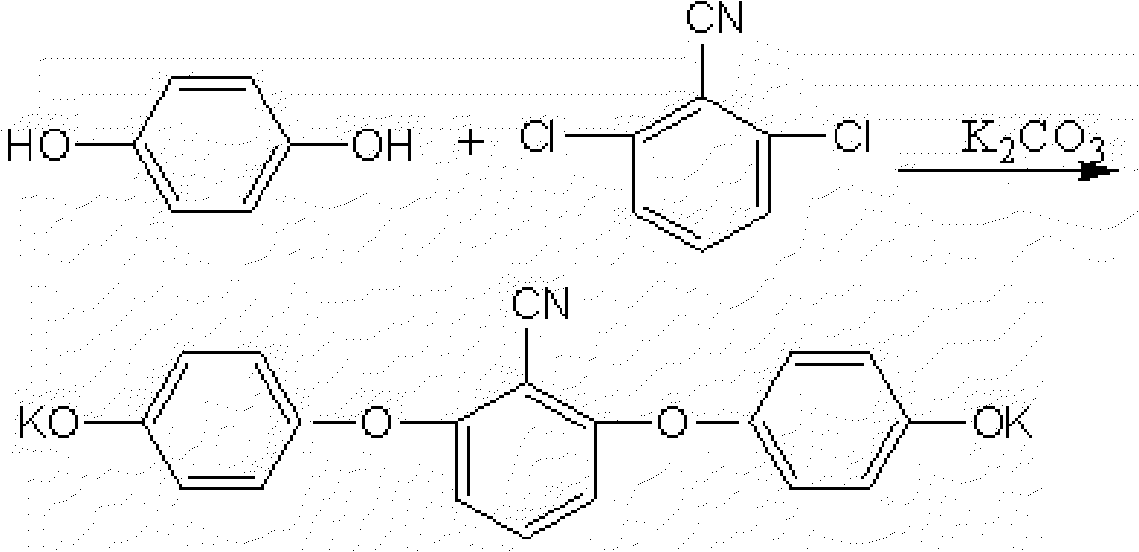

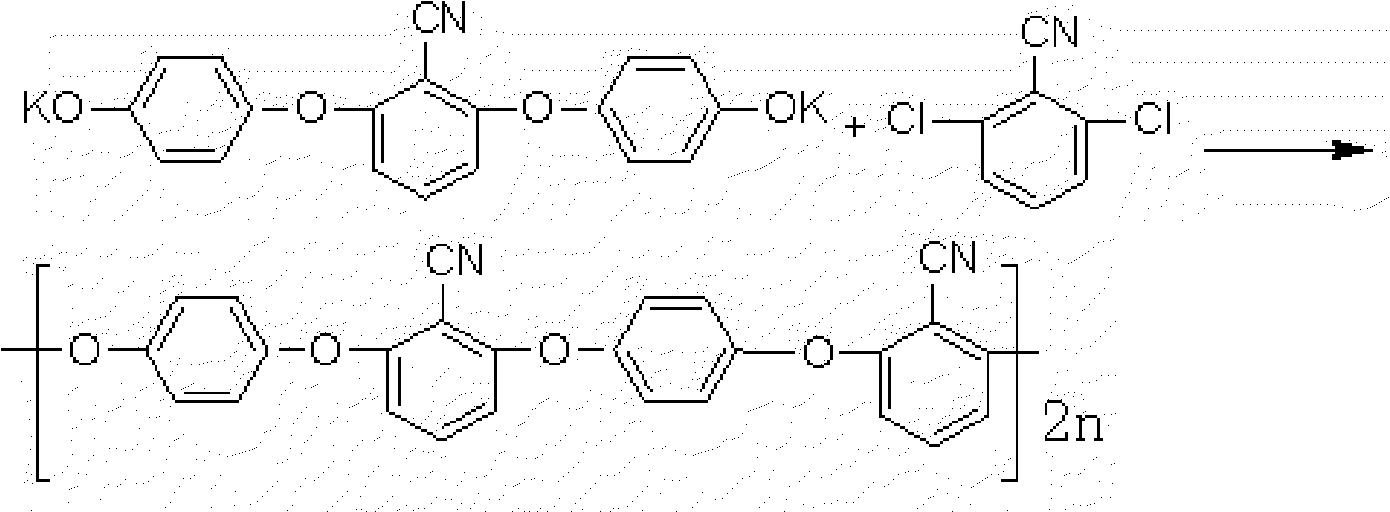

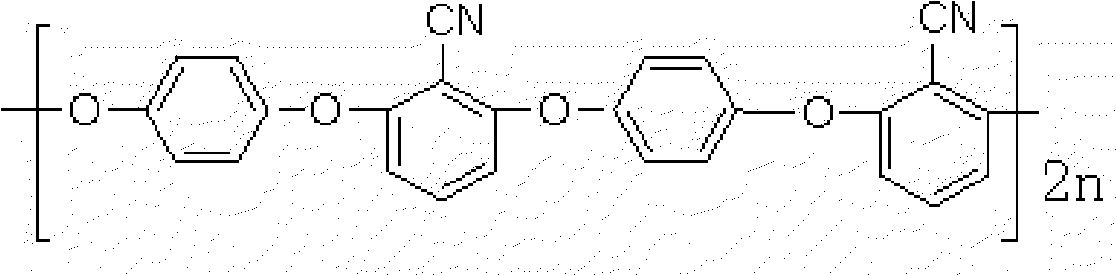

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 Preparation of semi-crystalline polyarylether ether nitrile of the present invention

[0026] (1) Preparation of materials:

[0027] 2,6 dichlorobenzonitrile 412.8 kg

[0028] Hydroquinone 264 kg

[0029] Anhydrous potassium carbonate (catalyst) 396 kg

[0030] Solvent NMP 748 kg

[0031] Toluene 60 kg

[0032] (2) Prepare the reactor:

[0033] The top of the sealed reaction kettle is connected to the water distributor through a valve, and the steam discharge pipe is connected to the top of the reaction kettle through a valve.

[0034] (3) Production process:

[0035] 1. Put the above-mentioned raw materials into the reaction kettle in order, and stir evenly.

[0036] 2. Heat the reactor to 160°C under normal pressure, keep it warm for 2 hours, and carry out dehydration and reflux reaction. The generated water is directly discharged from the water separator to the waste water storage tank, and the toluene is separated from the water separator and sen...

Embodiment 2

[0048] Embodiment 2 Preparation of semi-crystalline polyarylether ether nitrile of the present invention

[0049] (1) Preparation of materials:

[0050] 2,6 dichlorobenzonitrile 329.6 kg

[0051] Hydroquinone 211 kg

[0052] Anhydrous potassium carbonate (catalyst) 316.8 kg

[0053] Solvent NMP 565 kg

[0054] Toluene 50 kg

[0055] (2) Prepare the reactor:

[0056] The top of the sealed reaction kettle is connected to the water distributor through a valve, and the steam discharge pipe is connected to the top of the reaction kettle through a valve.

[0057] (3) Production process:

[0058] 1. Put the above-mentioned raw materials into the reaction kettle in order, and stir evenly.

[0059]2. Heat the reactor to 150°C under normal pressure, keep it warm for 3 hours, and carry out dehydration and reflux reaction. The generated water is directly discharged from the water separator to the waste water storage tank, and the toluene is separated from the water separator and se...

Embodiment 3

[0069] Embodiment 3 Preparation of semi-crystalline polyarylether ether nitrile of the present invention

[0070] (1) Preparation of materials:

[0071] 2,6 dichlorobenzonitrile 329.6 kg

[0072] Hydroquinone 211 kg

[0073] Anhydrous potassium carbonate (catalyst) 316.8 kg

[0074] Solvent NMP 565 kg

[0075] Toluene 50 kg

[0076] (2) Prepare the reactor:

[0077] The top of the sealed reaction kettle is connected to the water distributor through a valve, and the steam discharge pipe is connected to the top of the reaction kettle through a valve.

[0078] (3) Production process:

[0079] 1. Put the above-mentioned raw materials into the reaction kettle in order, and stir evenly.

[0080] 2. Heat the reactor to 140°C under normal pressure, keep it warm for 5 hours, and carry out dehydration and reflux reaction. The generated water is directly discharged from the water separator to the waste water storage tank, and the toluene is separated from the water separator and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com