Poly(aryl ether nitrile) composite material and its preparation method

A technology of polyarylether nitrile and composite materials, which is applied in the field of polymer nanocomposites, can solve the problems of polyarylether nitrile wear resistance, reduction of polyarylether nitrile comprehensive performance, poor processing fluidity and wear resistance, etc. , to achieve the effect of reducing application cost, eliminating internal stress, improving mechanical properties and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

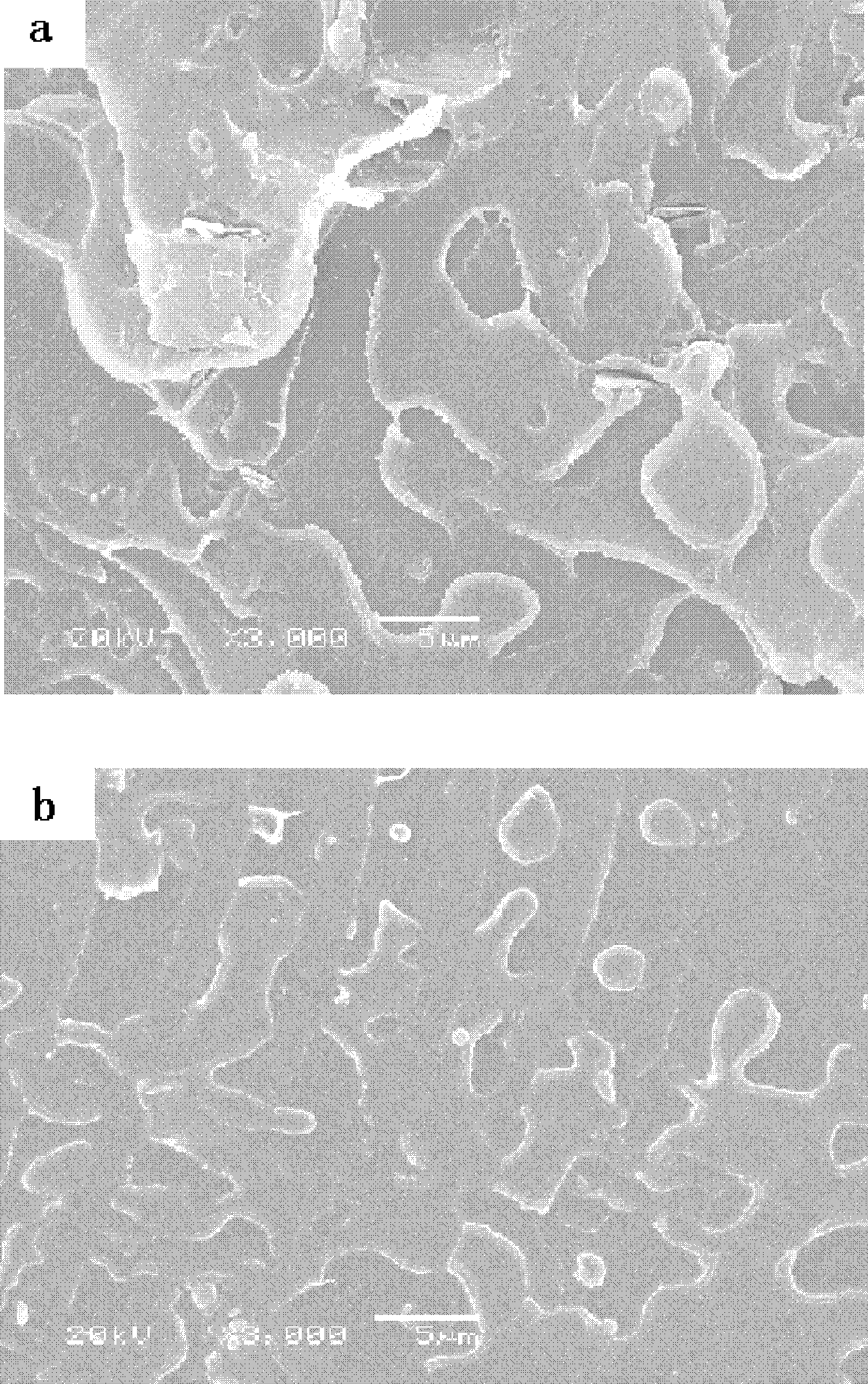

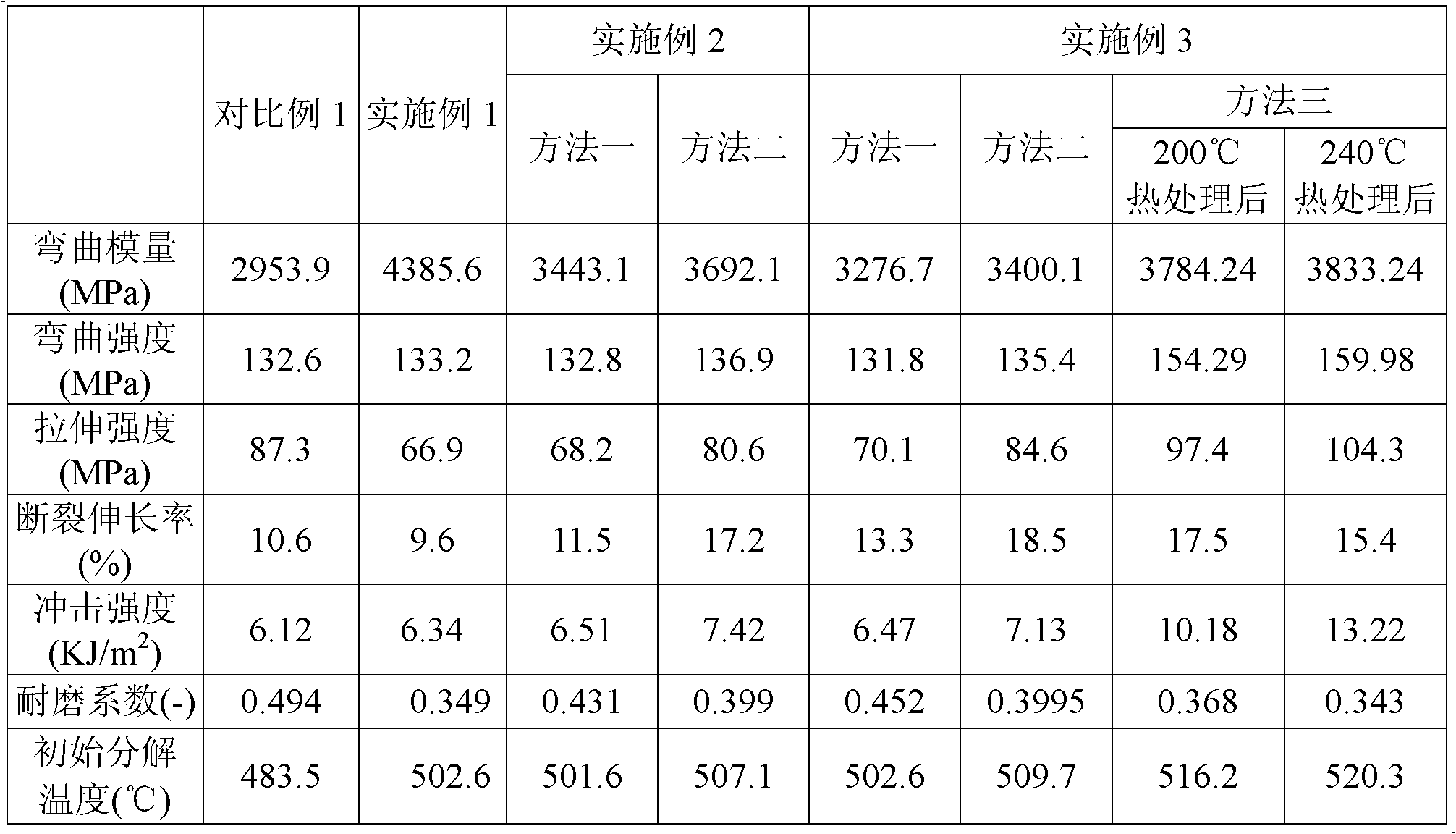

[0041] Embodiment 1 Preparation and performance of polyarylether nitrile composite material

[0042]Weigh 90 kg and 10 kg of polyarylether nitrile resin and graphene microflakes respectively, mix the polyarylether nitrile resin and graphene microflakes on a high-speed mixer, and then put them into a twin-screw extruder for melt blending and extrusion granulation A polyarylether nitrile composite material was prepared, wherein the melting temperature of the twin-screw extruder was 370°C. The physical performance indexes of the obtained polyarylether nitrile composite material are shown in Table 1.

Embodiment 2

[0043] Embodiment 2 Preparation and performance of polyarylether nitrile composite material

[0044] Method 1: Direct melt blending method

[0045] Weigh 95 kg and 5 kg of polyarylether nitrile resin and graphene microflakes respectively, mix polyarylether nitrile and graphene microflakes on a high-speed mixer, and then put them into a twin-screw extruder for melt blending and extrusion granulation. A polyarylether nitrile composite material was obtained, wherein the melting temperature of the twin-screw extruder was 370°C. The physical performance indexes of the obtained polyarylether nitrile composite material are shown in Table 1.

[0046] Method 2: masterbatch dilution method

[0047] (1) Preparation of polyarylether nitrile / graphene microchip masterbatch

[0048] Weigh 90 kg and 10 kg of polyarylether nitrile resin and graphene microflakes respectively, mix polyarylether nitrile and graphene microflakes on a high-speed mixer, and then put them into a twin-screw extrude...

Embodiment 3

[0051] Example 3 Preparation and performance of polyarylether nitrile composite material

[0052] Method 1: Direct Melt Blending

[0053] Weigh 99 kg and 1 kg of polyarylether nitrile resin and graphene microflakes respectively, mix polyarylether nitrile and graphene microflakes on a high-speed mixer, and then put them into a twin-screw extruder for melt blending and extrusion granulation. A polyarylether nitrile composite material was obtained, wherein the melting temperature of the twin-screw extruder was 370°C. The physical performance indexes of the obtained polyarylether nitrile composite material are shown in Table 1.

[0054] Method 2: masterbatch dilution method

[0055] The weight of polyarylether nitrile / graphene microchip masterbatch and polyarylether nitrile in embodiment 2 method two steps (2) is changed into 10 kilograms and 90 kilograms, and melting temperature is changed into 350 ℃; Other steps are all with implementation Example 2 is the same. The physical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wear coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com