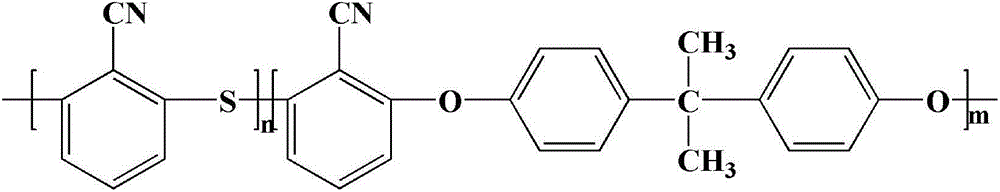

Bisphenol A type polyarylene sulfide ether nitrile resin and preparation method thereof

A polyarylene sulfide and ether nitrile technology is applied in the field of bisphenol A type polyarylene sulfide ether nitrile resin and its preparation, which can solve the problems of high production cost and processing temperature, and the heat resistance needs to be further improved, and achieves production The effect of cost reduction, easy realization of production conditions and low product price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

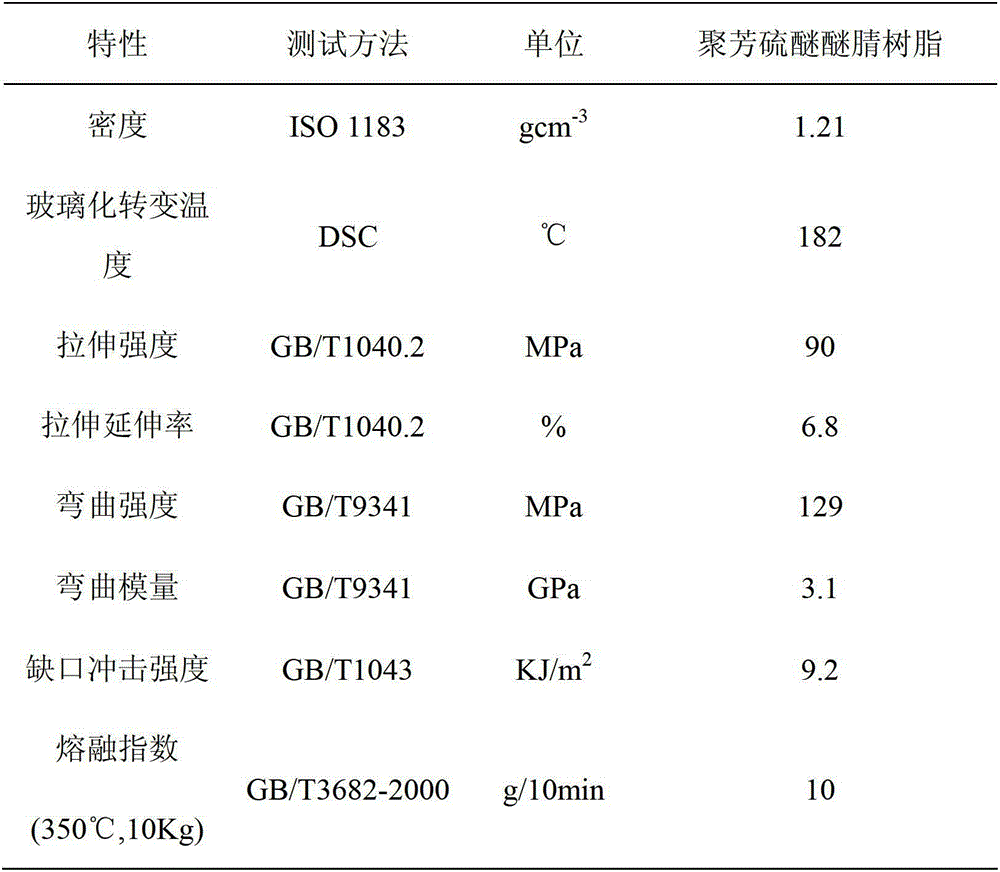

Embodiment example 1

[0026] Take 2,6-dichlorobenzonitrile:(n+m):potassium carbonate:N-methylpyrrolidone:toluene=1:1:(1.1~1.5):(6~8):(1.2~1.5) Molar ratio preparation, where n is the amount of sodium sulfide, m is the amount of bisphenol A, and the ratio of n to m is 1:9. Various raw materials were placed in a reactor with a water separator, a condenser, a stirrer and a heater, and the reaction was stirred at 140 to 170 ° C and normal pressure for 2 to 4 hours. When the high system temperature reaches 200°C, when the rod climbing phenomenon occurs, N-methylpyrrolidone is injected into the reaction kettle to dilute the reaction product, so that the reaction product can be quickly put into the precipitation kettle for precipitation. The obtained precipitate is dried and pulverized into particles with a particle size of 0.5-1.5 cm in a pulverizer, and then the particles are ground into fine powders in a size of 0.005-0.1 mm by a colloid mill. After the fine powder is soaked in methanol or ethanol org...

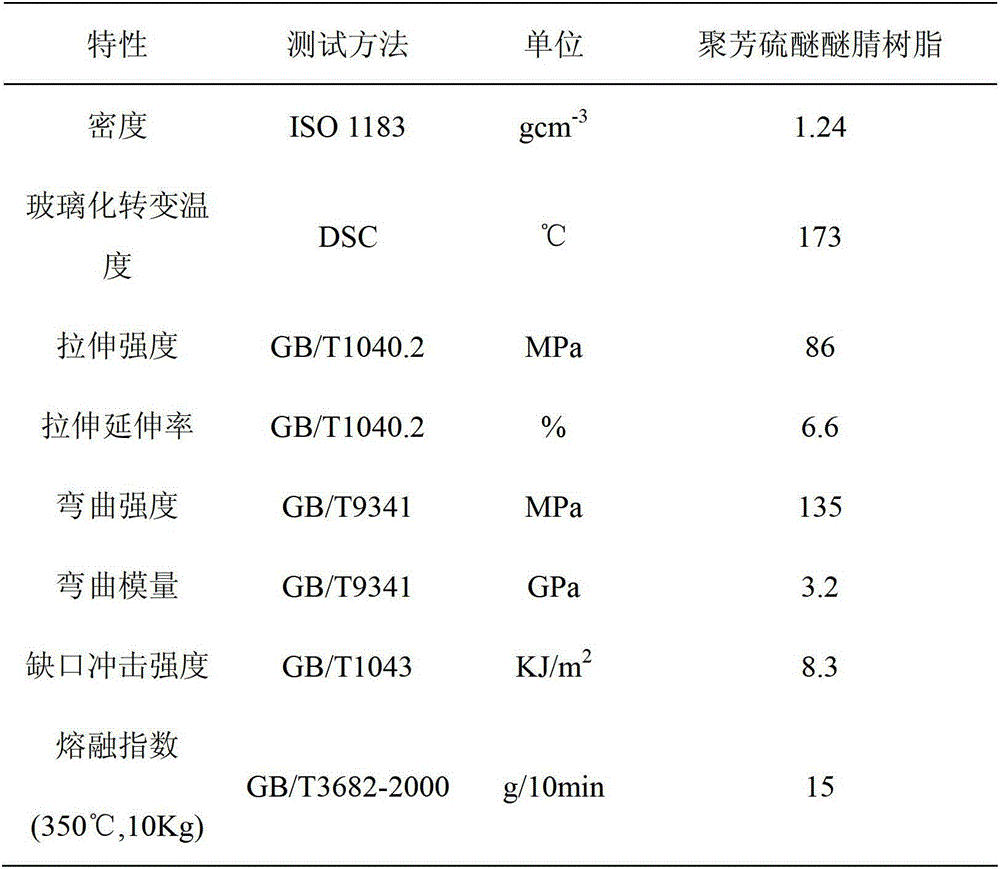

Embodiment 2

[0030] Take 2,6-dichlorobenzonitrile:(n+m):potassium carbonate:N-methylpyrrolidone:toluene=1:1:(1.1~1.5):(6~8):(1.2~1.5) Molar ratio preparation, where n is the amount of sodium sulfide, m is the amount of bisphenol A, and the ratio of n to m is 2:8. Various raw materials were placed in a reactor with a water separator, a condenser, a stirrer and a heater, and the reaction was stirred at 140 to 170 ° C and normal pressure for 2 to 4 hours. When the high system temperature reaches 200°C, when the rod climbing phenomenon occurs, N-methylpyrrolidone is injected into the reaction kettle to dilute the reaction product, so that the reaction product can be quickly put into the precipitation kettle for precipitation. The obtained precipitate is dried and pulverized into particles with a particle size of 0.5-1.5 cm in a pulverizer, and then the particles are ground into fine powders in a size of 0.005-0.1 mm by a colloid mill. After the fine powder is soaked in methanol or ethanol org...

Embodiment 3

[0034]Take 2,6-dichlorobenzonitrile:(n+m):potassium carbonate:N-methylpyrrolidone:toluene=1:1:(1.1~1.5):(6~8):(1.2~1.5) Molar ratio preparation, where n is the amount of sodium sulfide, m is the amount of bisphenol A, and the ratio of n to m is 3:7. Various raw materials were placed in a reactor with a water separator, a condenser, a stirrer and a heater, and the reaction was stirred at 140 to 170 ° C and normal pressure for 2 to 4 hours. When the high system temperature reaches 200°C, when the rod climbing phenomenon occurs, N-methylpyrrolidone is injected into the reaction kettle to dilute the reaction product, so that the reaction product can be quickly put into the precipitation kettle for precipitation. The obtained precipitate is dried and pulverized into particles with a particle size of 0.5-1.5 cm in a pulverizer, and then the particles are ground into fine powders in a size of 0.005-0.1 mm by a colloid mill. After the fine powder is soaked in methanol or ethanol orga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com