Solid Lubricant Polysaccharide Derivatives for Drilling Fluid

A solid lubricant and drilling fluid technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of unprepared, etc., and achieve the effect of easy biodegradation, stable properties and good lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

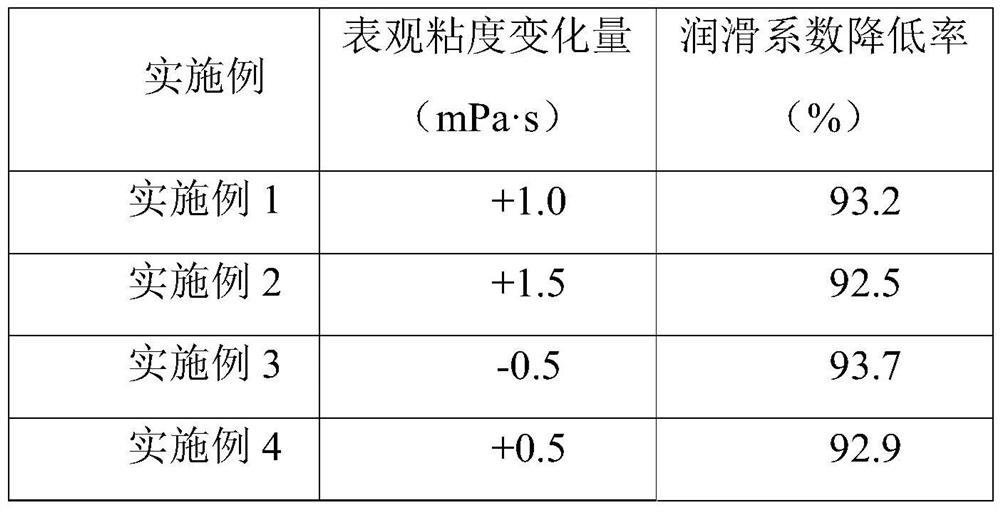

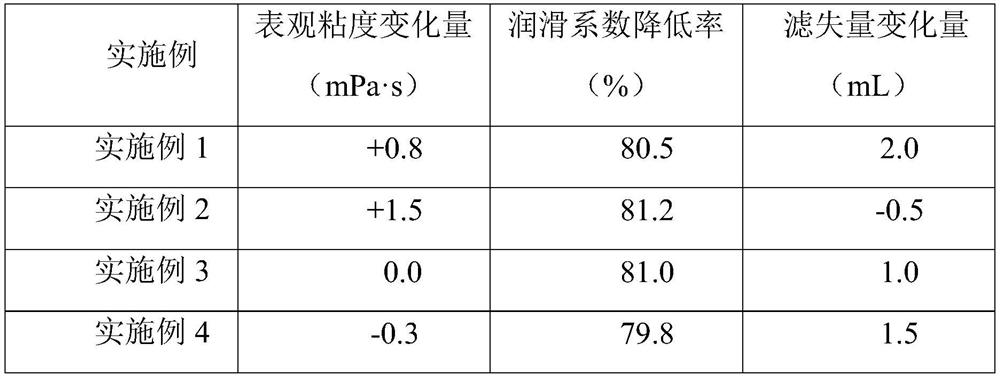

Examples

Embodiment 1

[0020] Embodiment 1: The solid lubricant polysaccharide derivative for drilling fluid of the present invention is made from the raw materials of following weight ratio: 30 parts of hydroxypropyl guar gum, 3 parts of propylene oxide, 0.1 parts of sodium hydroxide 20 parts of dodecyl alcohol, 0.15 parts of sulfuric acid catalyst, 10 parts of white oil, 2.5 parts of surfactant, 1 part of defoamer, 10 parts of mica powder, 1 part of bactericide, 6 parts of ethanol, and 20 parts of water; Described white oil is the combination of No. 7 white oil and No. 10 white oil two kinds of raw materials, and its weight ratio is 1: 1; Described catalyst sulfuric acid is the sulfuric acid aqueous solution that molar concentration is 0.1mol / L; Described surface Active agent is the combination of two kinds of raw materials of OP-10 surfactant and AEO-9 surfactant, and the weight ratio of OP-10 surfactant and AEO-9 surfactant is 1: 1.5; Described defoamer It is polyoxyethylene oxypropylene glyceri...

Embodiment 2

[0022] Embodiment 2: The solid lubricant polysaccharide derivative for drilling fluid of the present invention is made from the raw materials of following weight ratio: 40 parts of hydroxypropyl guar gum, 4 parts of propylene oxide, 0.15 parts of sodium hydroxide 25 parts of dodecyl alcohol, 0.2 parts of phosphoric acid catalyst, 12 parts of white oil, 3 parts of surfactant, 2 parts of defoamer, 12 parts of mica powder, 2 parts of bactericide, 8 parts of ethanol, and 10 parts of water; Described white oil is the combination of No. 7 white oil and No. 10 white oil, and the weight ratio of No. 7 white oil and No. 10 white oil is 1: 2; Described catalyst phosphoric acid is the phosphoric acid that molar concentration is 0.1mol / L aqueous solution; the surfactant is OP-10 surfactant; the defoamer is polydimethylsiloxane; the fungicide is starch preservative DL-D401.

[0023] The preparation method of the described solid lubricant polysaccharide derivative for drilling fluid compris...

Embodiment 3

[0024] Embodiment 3: the solid lubricant polysaccharide derivative for drilling fluid of the present invention is made from the raw materials of following weight ratio: 32 parts of hydroxypropyl guar gum, 3 parts of propylene oxide, 0.15 parts of sodium hydroxide 20 parts of dodecyl alcohol, 0.15 parts of catalyst, 15 parts of white oil, 3 parts of surfactant, 2 parts of defoamer, 10 parts of mica powder, 2 parts of bactericide, 8 parts of ethanol, and 18 parts of water; White oil is the combination of No. 7 white oil and No. 10 white oil, and the weight ratio of No. 7 white oil and No. 10 white oil is 1: 2; Described catalyzer is the combination of two kinds of raw materials of hydrochloric acid and sulfuric acid, and its weight ratio is 1: 1, described hydrochloric acid is the hydrochloric acid aqueous solution that molar concentration is 0.1mol / L, and described sulfuric acid is the sulfuric acid aqueous solution that molar concentration is 0.1mol / L; Described tensio-active a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com