Composite carbon fiber spectacle frame and preparation process thereof

A technology of composite carbon fiber and preparation process, applied in the field of glasses, can solve the problems of high production cost of carbon fiber glasses frames, lower radial strength than axial strength, and great influence of carbon fiber strength, etc., and achieves good curing effect, improved wear resistance, Good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

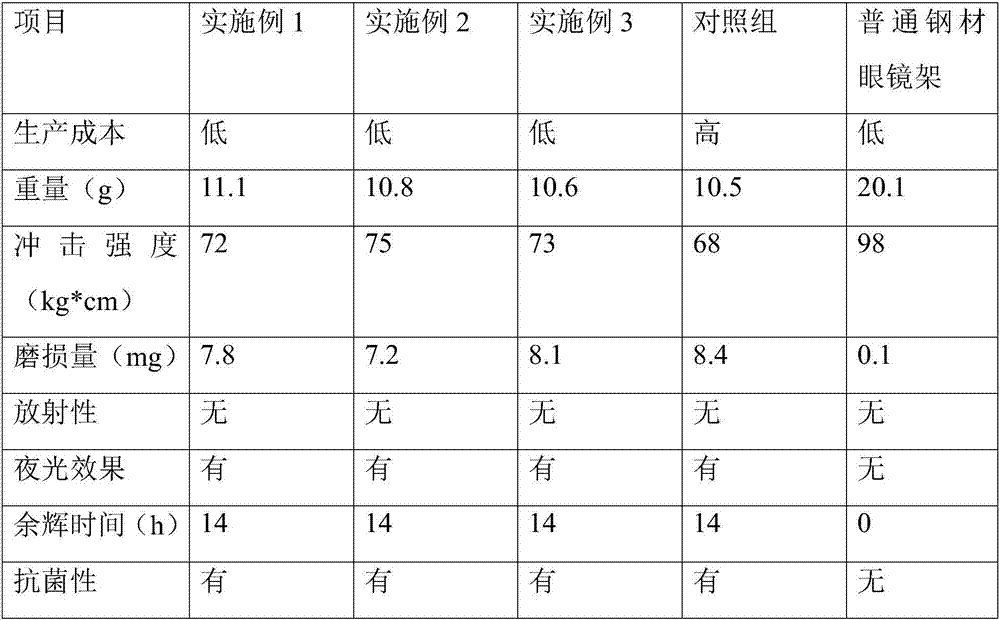

Examples

specific Embodiment 1

[0029]The composite carbon fiber spectacle frame is made of the following raw materials in parts by weight: 10 parts of carbon fiber, 23 parts of acetate fiber, 60 parts of epoxy resin, 3 parts of wear-resistant agent, 1 part of antibacterial agent, 0.5 part of luminous material, and 0.5 part of antioxidant , 1 part of coupling agent, 0.5 part of lubricant, 0.5 part of compatibilizer.

[0030] Among them, the wear-resistant agent is a mixture of graphite and polytetrafluoroethylene; the antibacterial agent is nano-silver; the luminous material is Zn 3 Ga 2 Ge 2 o 10 :Cr 3+ , the particle size of the material is 200nm; the antioxidant is antioxidant 1010 [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol and antioxidant 168 (three (2,4-di tert-butylphenyl) phosphite) mixture; coupling agent is aminosilane coupling agent; lubricant is stearylamide lubricant; described compatibilizer is the copolymer of styrene and maleic anhydride, The length of the carb...

specific Embodiment 2

[0031] The composite carbon fiber spectacle frame is made of the following raw materials in parts by weight: 20 parts of carbon fiber, 21 parts of acetate fiber, 52 parts of epoxy resin, 1 part of wear-resistant agent, 1 part of antibacterial agent, 0.5 part of luminous material, and 0.5 part of antioxidant , 3 parts of coupling agent, 0.5 part of lubricant, 0.5 part of compatibilizer.

[0032] Among them, the wear-resistant agent is a mixture of graphite and polytetrafluoroethylene; the antibacterial agent is nano-silver; the luminous material is Zn 3 Ga 2 Ge 2 o 10 :Cr 3+ , the particle size of the material is 200nm; the antioxidant is antioxidant 1010 [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol and antioxidant 168 (three (2,4-di tert-butylphenyl) phosphite) mixture; coupling agent is aminosilane coupling agent; lubricant is stearylamide lubricant; described compatibilizer is the copolymer of styrene and maleic anhydride, The length of the car...

specific Embodiment 3

[0033] The composite carbon fiber spectacle frame is made of the following raw materials in parts by weight: 20 parts of carbon fiber, 21 parts of acetate fiber, 52 parts of epoxy resin, 1 part of wear-resistant agent, 1 part of antibacterial agent, 0.5 part of luminous material, and 0.5 part of antioxidant , 3 parts of coupling agent, 0.5 part of lubricant, 0.5 part of compatibilizer.

[0034] Among them, the wear-resistant agent is a mixture of graphite and polytetrafluoroethylene; the antibacterial agent is nano-silver; the luminous material is Zn 3 Ga 2 Ge 2 o 10 :Cr 3+ , the particle size of the material is 200nm; the antioxidant is antioxidant 1010 [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol and antioxidant 168 (three (2,4-di tert-butylphenyl) phosphite) mixture; coupling agent is aminosilane coupling agent; lubricant is stearylamide lubricant; described compatibilizer is the copolymer of styrene and maleic anhydride, The length of the car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com