Solution pH adjustment method based on graphene quantum dots

A technology of graphene quantum dots and pH adjustment, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve problems such as unsuitable for large-scale production, difficult to separate impurities, low degree of graphitization, etc., and achieve clean edges without impurities Effects of functional groups, high purity of finished products, and high degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the preparation of graphene quantum dot

[0034] The preparation method of graphene quantum dots comprises the following steps: ① take graphite powder block and mechanically mix it with molten salt catalyst; ② take the mixed material in step ①, preheat and keep it warm; ③ take the mixed material in step ② after heat preservation and directly heat up and heat preservation; ④ After cooling the mixture in step ③ to room temperature, soak it in water to obtain the suspension; ⑤ Take the suspension in step ④, and obtain the graphene quantum dot product through centrifugal filtration.

[0035] In step ①, the mass ratio of graphite powder block to molten salt catalyst is 1:2 to 1:8, preferably 1:5 in this embodiment.

[0036] In step ①, the graphite powder block is industrial-grade graphite powder. The ash content of the graphite powder block in this embodiment is not more than 0.05, the moisture content is not higher than 0.02, the carbon content is more than 99...

Embodiment 2

[0042]Embodiment 2: Preparation of boron nitride quantum dots

[0043] The preparation method of boron nitride quantum dots, the raw material is hexagonal boron nitride, and the rest are the same as in embodiment 1.

[0044] Result analysis:

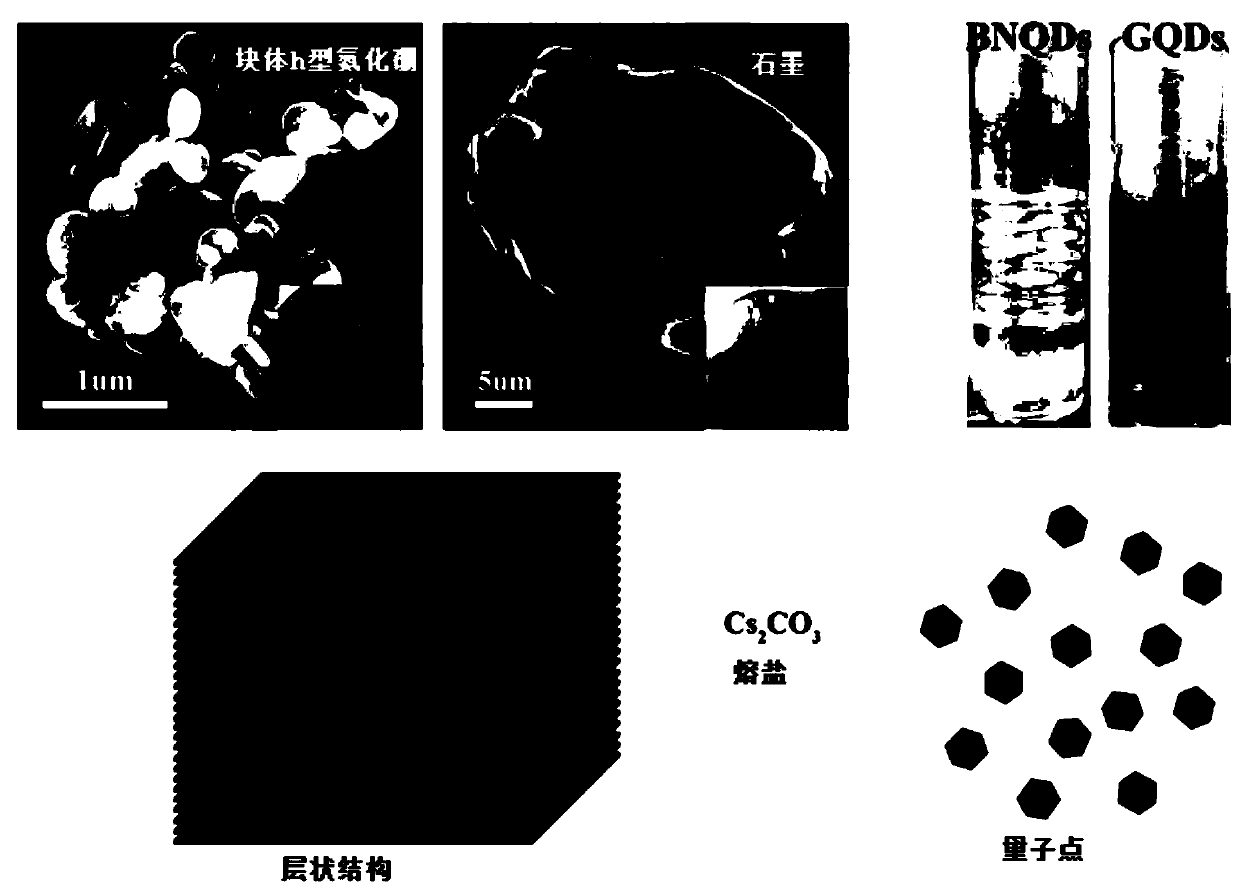

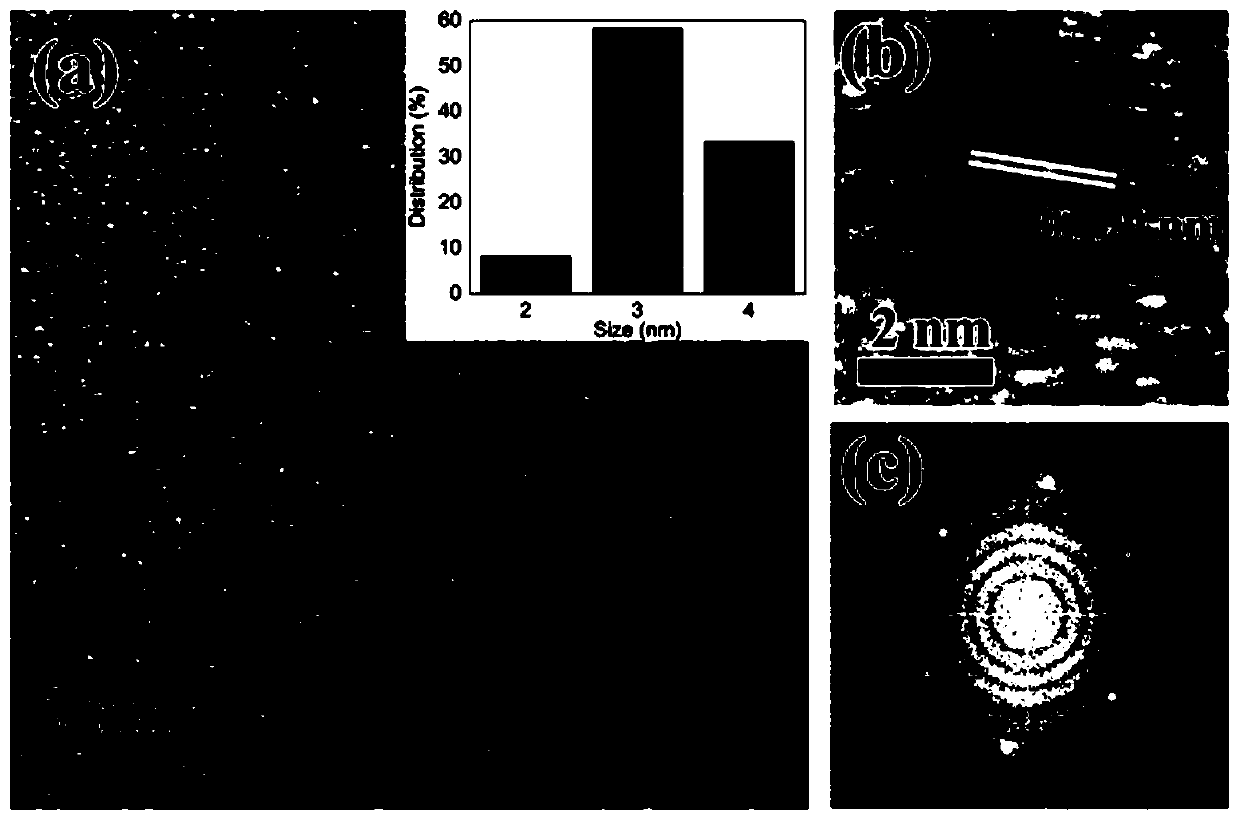

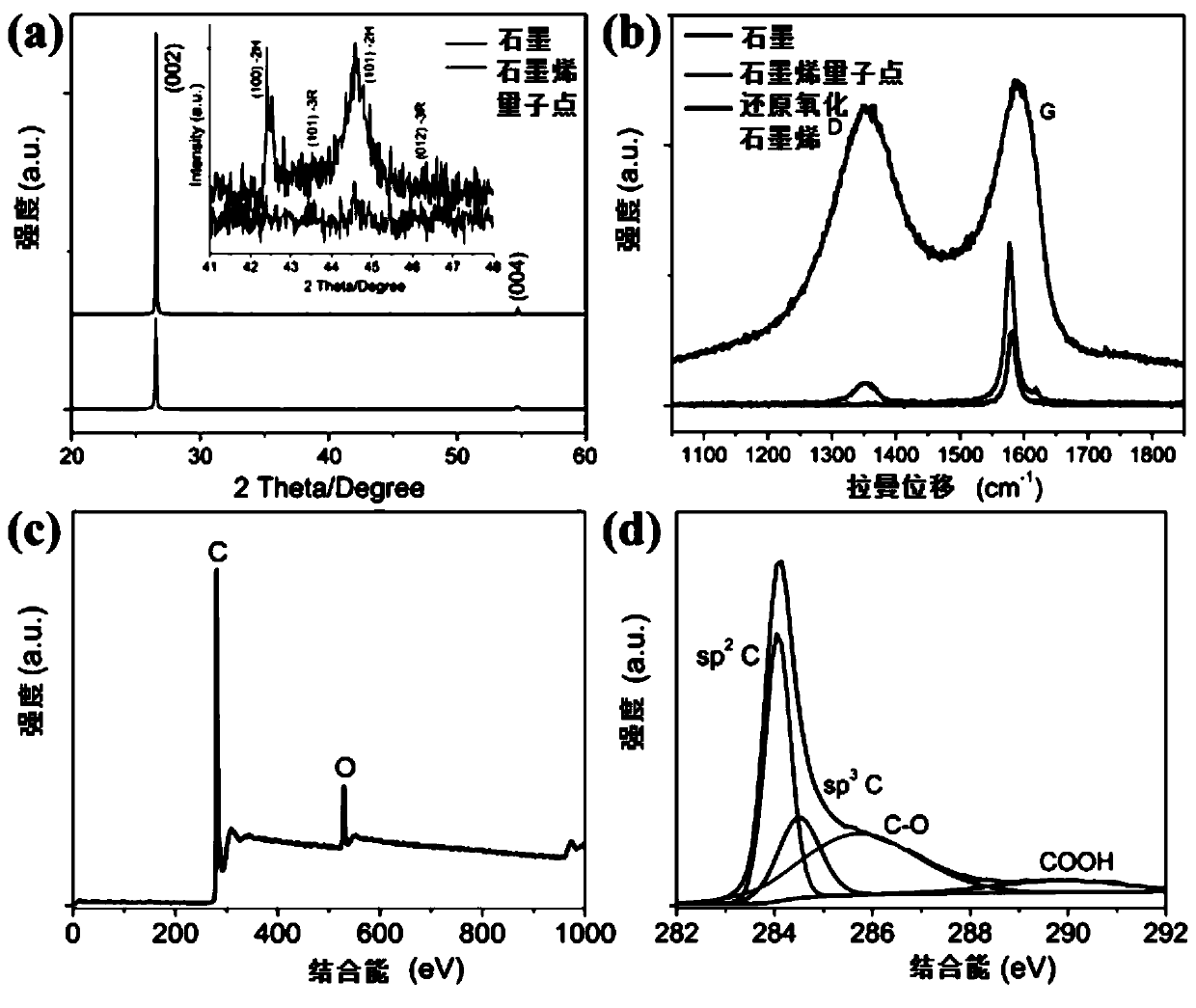

[0045] figure 1 It is the electron micrograph of the raw material graphite powder block and boron nitride, the macroscopic picture of the product solution and the schematic diagram of the reaction.

[0046] Depend on figure 1 It can be seen that the schematic preparation process of graphene quantum dots and boron nitride quantum dots. Diluted GQDS (5mg / ml) is transparent with black particles in suspension. The low water solubility and metallic luster indicate that it has less hydrophilic functional groups, which is totally different from the previously reported carbon quantum dots (CQDS). BNQDs (5mg / ml) are milky white. Both GQDs and BNQDs tend to precipitate and aggregate. This is the result of a small amount of hydrophilic funct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com