Oak board color wiping system and color wiping process

A technology of oak boards and craftsmanship, applied in the field of furniture, can solve the problems of poor furniture appearance, uneven color rubbing, high labor costs, etc., and achieve the effect of vivid wood grain effect, high degree of automation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

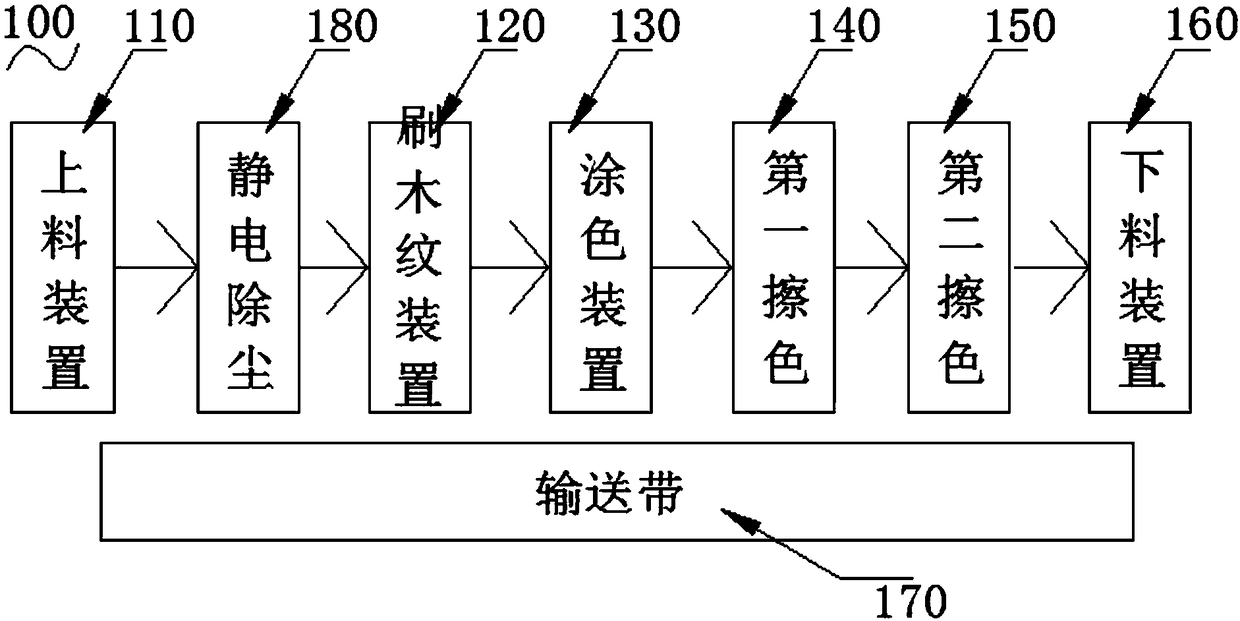

[0022] like figure 1 Shown is a schematic structural view of the oak board color erasing system of the present invention.

[0023] The oak board color erasing system 100 includes a feeding device 110, a wood grain brushing device 120, a coloring device 130, a first color erasing device 140, a second color erasing device 150 and a blanking device 160, and also includes a device for transporting oak boards. The conveyor belt 170 passes through the feeding device 110 , the wood grain brushing device 120 , the first color wiping device 140 , the second color wiping device 150 and the unloading device 160 in sequence.

[0024] On the one hand, the oak board is fed by the feeding device 110, the wood grain brushing device 120 brushes out the wood grain on the surface of the oak board through a wire brush, and then the paint is painted on the surface of the oak board by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com