Method for preparing aluminium iron polychloride floculant

A technology of polyaluminum chloride and iron floc, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., to achieve the effects of process innovation, product stability, and consumption saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

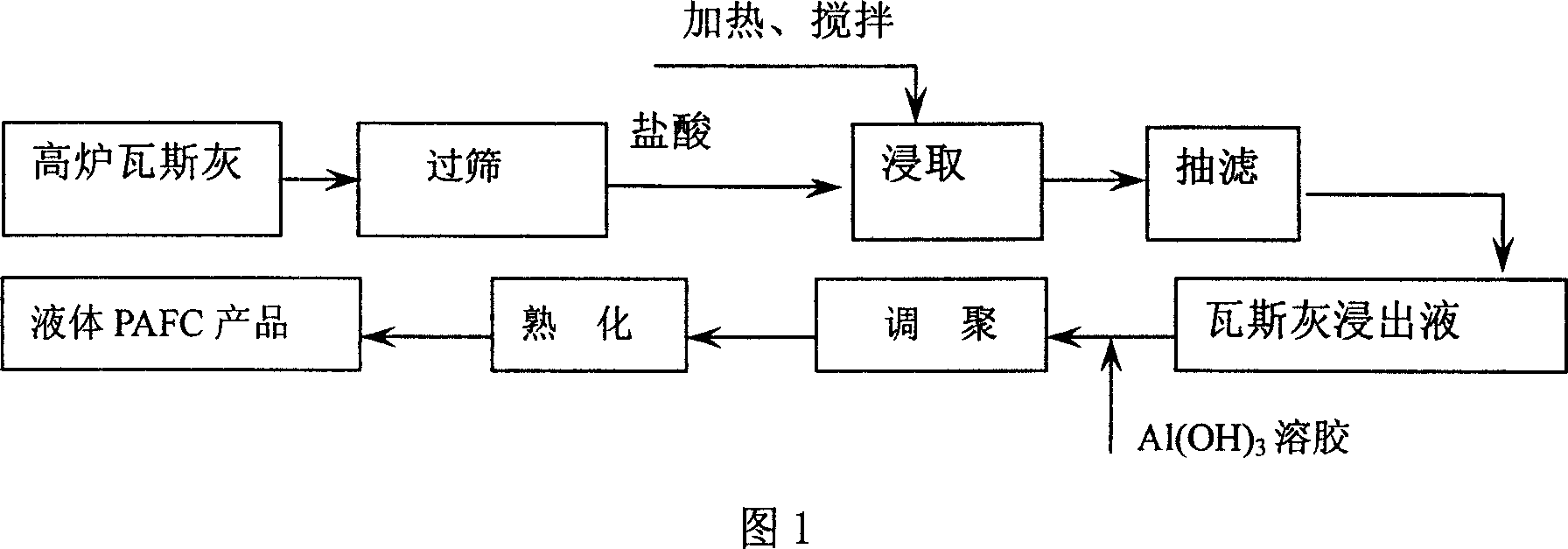

[0028] As shown in Figure 1, the preparation of composite inorganic macromolecule flocculant polyaluminum ferric chloride liquid product by using steel mill waste blast furnace gas ash comprises the following steps:

[0029] (1) Raw material selection: the Fe 2 o 3 The content is 24.32%, Al 2 o 3 Steel plant waste blast furnace gas ash with a content of 8.42% is naturally air-dried and passed through a 60-mesh sieve for subsequent use;

[0030] (2) Laboratory preparation of blast furnace gas ash dissolution solution: take 50g blast furnace gas ash, put it into a 500mL four-neck flask with a stirrer, thermometer and reflux device, add 2gNaF, and add 6mL mass percentage concentration while stirring. 49% HNO 3 To oxidize the ferrous iron in the blast furnace gas ash, use a hydrochloric acid solution with a mass percent concentration of 18% at a gray-acid ratio of 1:3 and a reaction temperature of 100-105°C for 3 hours to make the iron in the material , aluminum is dissolved ...

Embodiment 2

[0034] The method for preparing polyaluminum ferric chloride liquid flocculant by using steel mill waste blast furnace gas ash comprises the following steps:

[0035] (1) Raw material selection: the Fe 2 o 3 The content is 21.2%, Al 2 o 3Steel plant waste blast furnace gas ash with a content of 7.8% is passed through a 60-mesh sieve after natural air-drying, and is set aside;

[0036] (2) Laboratory preparation of blast furnace gas ash dissolution solution: take 50g blast furnace gas ash, put it into a 500mL four-neck flask with a stirrer, thermometer and reflux device, add 2gNaF, and add 6mL mass percentage concentration while stirring. 49% HNO 3 To oxidize the ferrous iron in the blast furnace gas ash, use a hydrochloric acid solution with a mass percent concentration of 18% at a gray-acid ratio of 1:4 and a reaction temperature of 70 to 85°C for 2 hours to make the iron in the material , aluminum is dissolved in the liquid phase to the greatest extent, and then suction...

Embodiment 3

[0040] The method for preparing polyaluminum ferric chloride liquid flocculant by using steel mill waste blast furnace gas ash comprises the following steps:

[0041] (1) Raw material selection: the Fe 2 o 3 The content is 25.2%, Al 2 o 3 Steel plant waste blast furnace gas ash with a content of 8.8% is passed through a 60-mesh sieve after natural air-drying, and is set aside;

[0042] (2) Laboratory preparation of blast furnace gas ash dissolution solution: take 50g blast furnace gas ash, put it into a 500mL four-neck flask with a stirrer, thermometer and reflux device, add 2gNaF, and add 6mL mass percentage concentration while stirring. 49% HNO 3 To oxidize the ferrous iron in the blast furnace gas ash, use a hydrochloric acid solution with a mass percent concentration of 18% at a gray-acid ratio of 1:2 and a reaction temperature of 50 to 65°C, and stir for 4 hours to make the iron in the material , aluminum is dissolved in the liquid phase to the greatest extent, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com