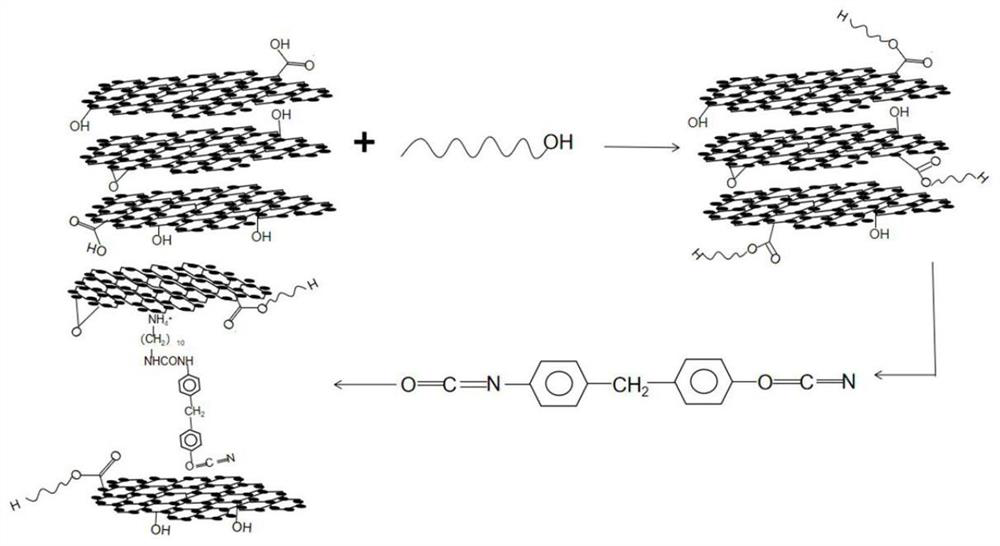

Preparation method of graphene/waste polyurethane composite material

A composite material, graphene technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of black material consumption, long time, secondary pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

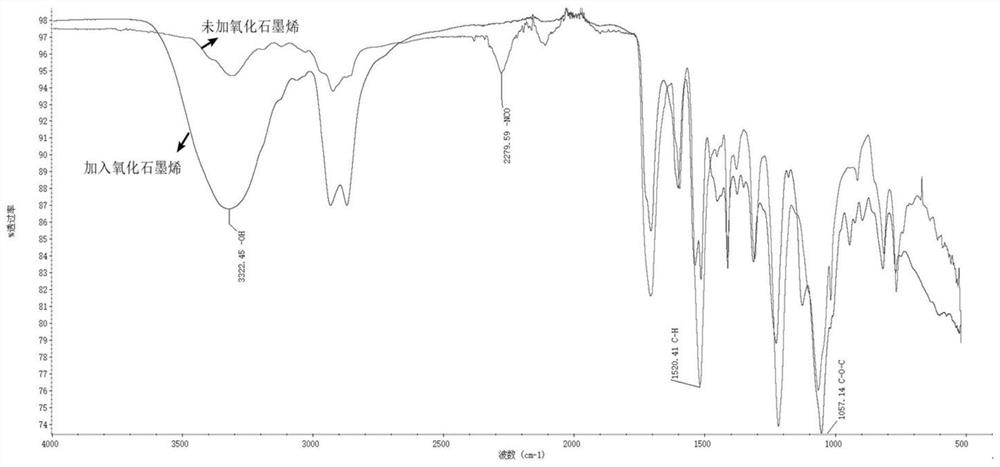

Method used

Image

Examples

Embodiment 1

[0048] A kind of preparation method of graphene / waste and old polyurethane composite material, comprises the following steps:

[0049] (1) Mix 0.5g of graphene oxide with 30g of butanediol, 35g of hydroxyethyl cellulose, 10g of pentaerythritol and 35g of triethanolamine. After ultrasonic oscillation for 2 hours, add it to the reaction kettle, and add 100g of waste polyurethane foam. The mixture was stirred for 3 hours, and the degradation product polyol was obtained after cooling to room temperature.

[0050] (2) Stir 30g of degradation product polyol with 0.2g of triethanolamine, 15g of HCFC-141b, 0.2g of organic selenium, and 3g of silicone oil CGY-5 and use it as a white material, then stir with 49.40g of PAPI-27 for 18s to make it foam, After cooling, a hard polyurethane material is obtained.

Embodiment 2

[0052] A kind of preparation method of graphene / waste and old polyurethane composite material, comprises the following steps:

[0053] (1) 0.5g graphene oxide is mixed with 30g1,2-propanediol, 35g hydroxyethyl cellulose, 10g pentaerythritol and 35g triethanolamine, after ultrasonic vibration 2h, add in the reactor, and add 100g waste polyurethane foam, in 180 Stirring at ℃ for 4.5 hours, cooling to room temperature to obtain the degradation product polyol.

[0054] (2) After mixing 20g of degradation product polyol with 10g of polyester polyol, 0.2g of isosorbide, 15g of antimony trioxide, 0.2g of tris(dimethylaminopropyl)hexahydrotriazine, and 3g of silicone oil CGY-5 As a white material, it was stirred with 48.50g of PAPI-27 for 15s to make it foam, and cooled to obtain a rigid polyurethane material.

Embodiment 3

[0056] A kind of preparation method of graphene / waste and old polyurethane composite material, comprises the following steps:

[0057] (1) Mix 0.5g of graphene oxide with 30g of 1,2-propanediol, 35g of 1,2-cyclopentadiol, 10g of pentaerythritol and 35g of diethanolamine, after ultrasonic oscillation for 2h, add to the reaction kettle, and add 100g of waste polyurethane foam, Stir at 150° C. for 4.5 hours, and cool to room temperature to obtain the degradation product polyol.

[0058] (2) Stir 25g of degradation product polyol with 5g of polyester polyol, 0.3g of glycerin, 15g of HCFC-141b, 0.2g of titanium glycol, and 3g of silicone oil L-600 as a white material, and then mix it with 48.20g of PAPI-27 Stir for 20s to make it foam, and cool to obtain a rigid polyurethane material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com