Harmless treatment device for sludge

A technology of harmless treatment and sludge, applied in biological sludge treatment, sludge treatment through temperature control, etc., can solve the problems of easy blockage, low environmental protection value, unreasonable design, etc., to improve treatment efficiency and environmental protection. High value, novel structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

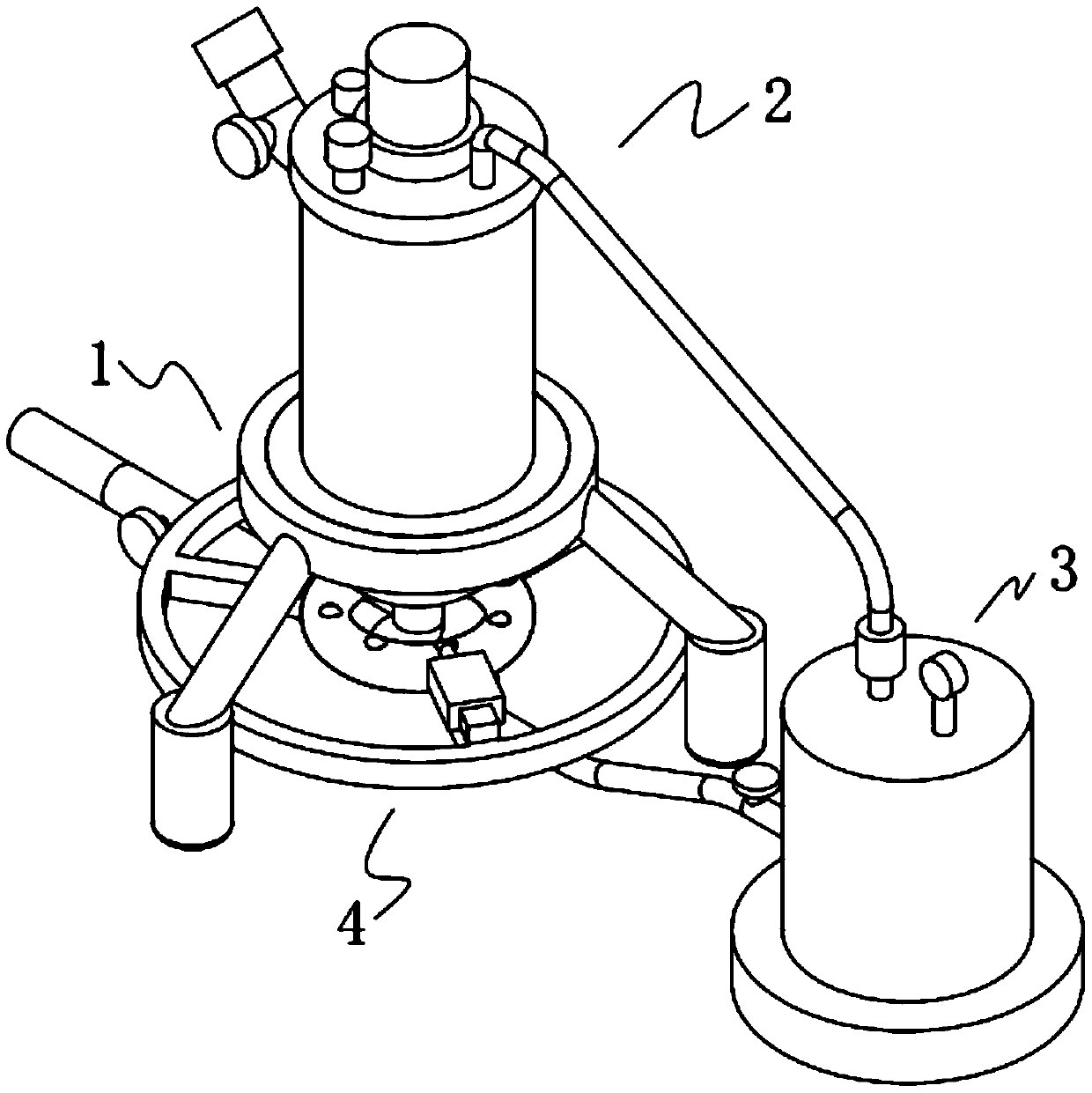

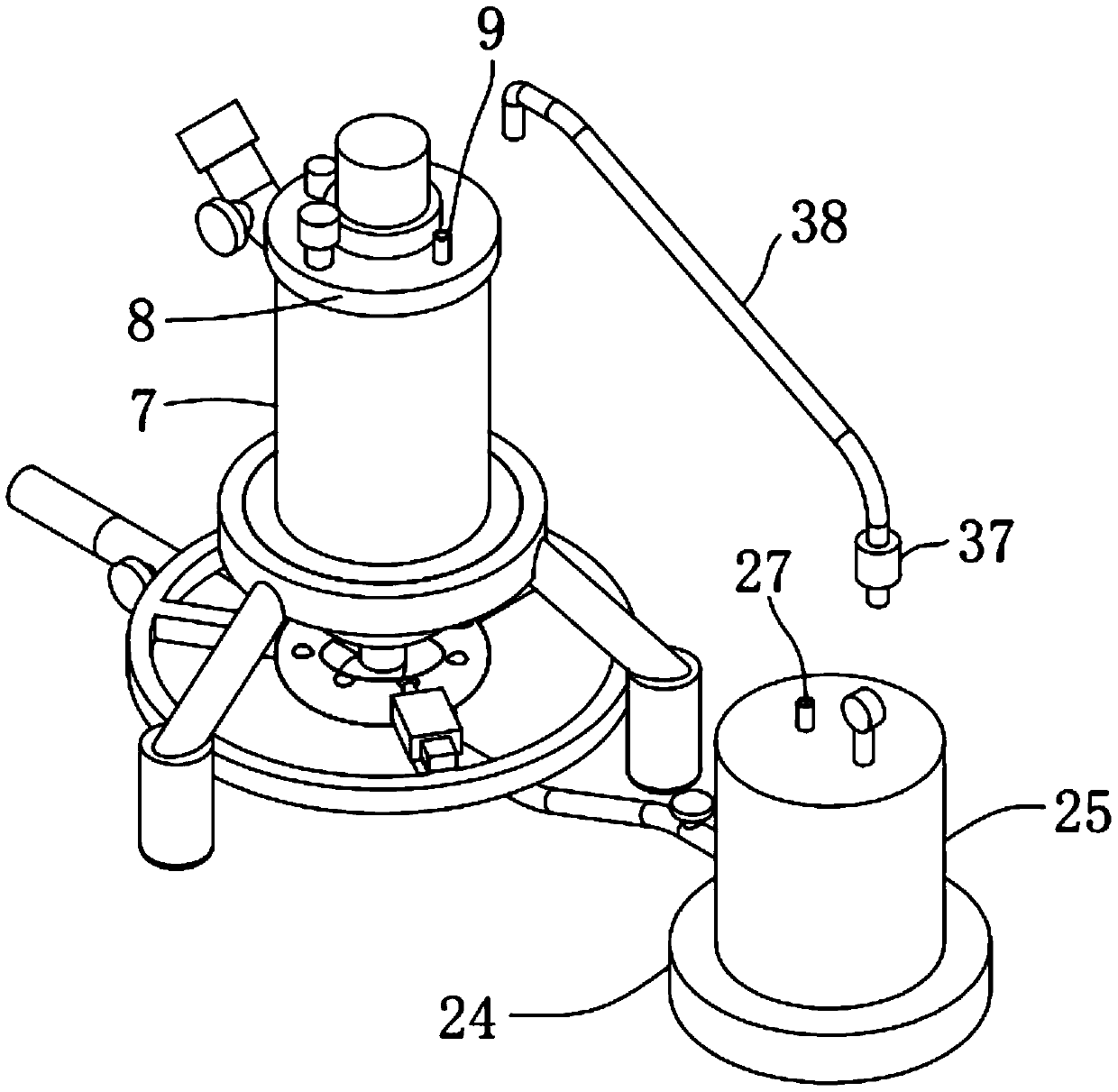

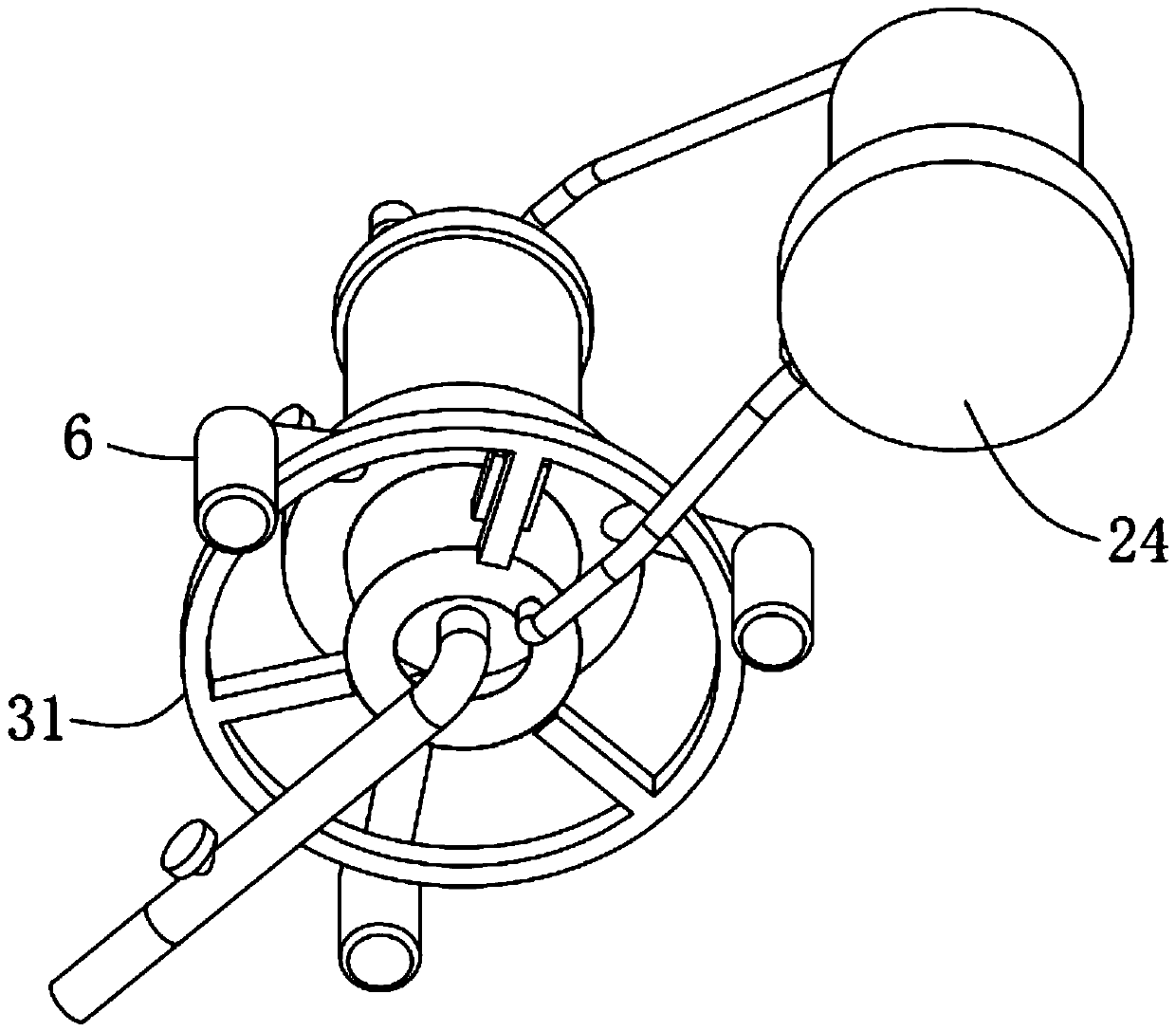

[0047] A sludge harmless treatment device, such as figure 1 As shown, it includes a bottom fixed unit 1, and also includes a sludge harmless treatment unit 2, a gas storage unit 3, and a combustion heating unit 4, and the sludge harmless treatment unit 2 is fixedly installed on the bottom fixed unit 1 , the gas storage unit 3 is connected to the sludge harmless treatment unit 2, the combustion heating unit 4 is connected to the gas storage unit 3, and the combustion heating unit 4 is fixedly installed on the bottom Bottom interior of fixed unit 1.

[0048] By adopting the above technical scheme, the bottom fixed unit 1 is used to install the sludge harmless treatment unit 2 and the combustion heating unit 4; the sludge harmless treatment unit 2 is used to perform harmless anaerobic fermentation treatment on the sludge, so that The organic matter in the sludge (such as human, livestock and poultry manure, straw, weeds, etc.) is decomposed and metabolized by various microorgani...

Embodiment 2

[0069] The difference from Example 1 is that a protective layer is also provided on the inner surface of the tank body 7, and the protective layer is prepared by the following method:

[0070] Take the following raw materials and weigh them by weight: 20-30 parts of epoxy resin, 8-12 parts of calcium carbonate powder, 10-12 parts of titanium dioxide powder, 14-18 parts of phenolic resin, 13-15 parts of aluminum oxide powder, 15-18 parts of tetrafluoroethylene, 12-14 parts of acrylic emulsion, 3-5 parts of alcohol ester dodecane, 3-5 parts of triethanolamine, 2-4 parts of emulsified silicone oil and 30-50 parts of water;

[0071] S1. Add the weighed acrylic emulsion, alcohol ester dodeca, triethanolamine, emulsified silicone oil and water into the mixer and stir for 20-30min at a stirring speed of 500-700r / min to prepare a mixed solution;

[0072] S2. Adding epoxy resin, calcium carbonate powder, titanium dioxide powder, phenolic resin, aluminum oxide powder and polytetrafluoro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com