Water-based color-changing-resistant varnish and coating process thereof

A discoloration-resistant, water-based technology, which is applied to the surface coating liquid device, coating, polyurea/polyurethane coating, etc., can solve the problem of discoloration of African mahogany woodware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The embodiment of the present invention provides a method for using the water-based natural texture varnish for African mahogany woodware described in the above technical solution or the water-based natural texture varnish for woodware obtained by the preparation method described in the above technical solution, comprising the following steps:

[0046] The discoloration-resistant water-based discoloration-resistant varnish primer for African mahogany woodware described in the above scheme or the discoloration-resistant water-based discoloration-resistant varnish primer for African mahogany woodware obtained by the method described in the above scheme is mixed with water to obtain a durable coating for African mahogany woodware. Color-changing water-based tarnish-resistant varnish primer;

[0047] The preparation method of the water-based African mahogany woodware with color-resistant water-based color-resistant varnish finish is as follows:

[0048] First, the water-bas...

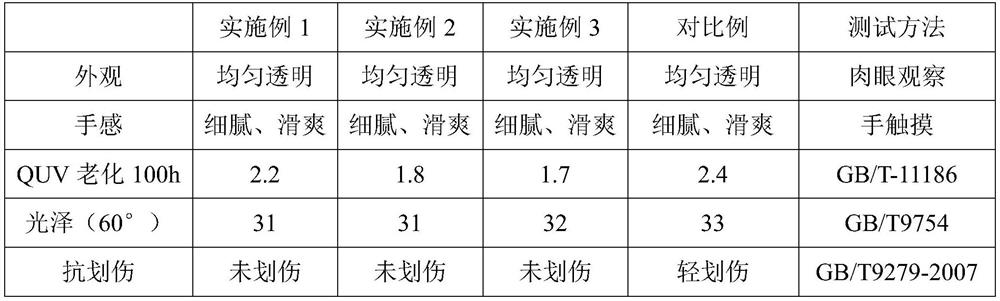

Embodiment 1~3

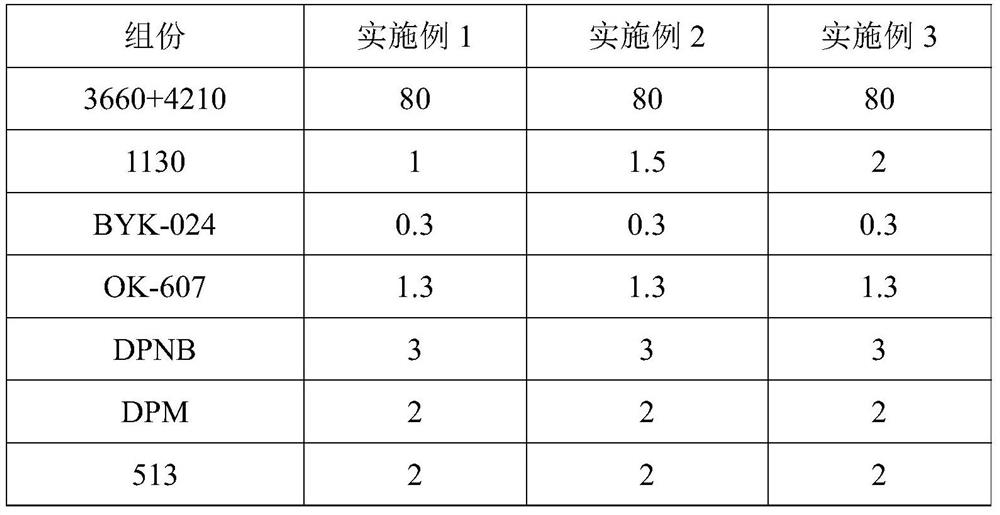

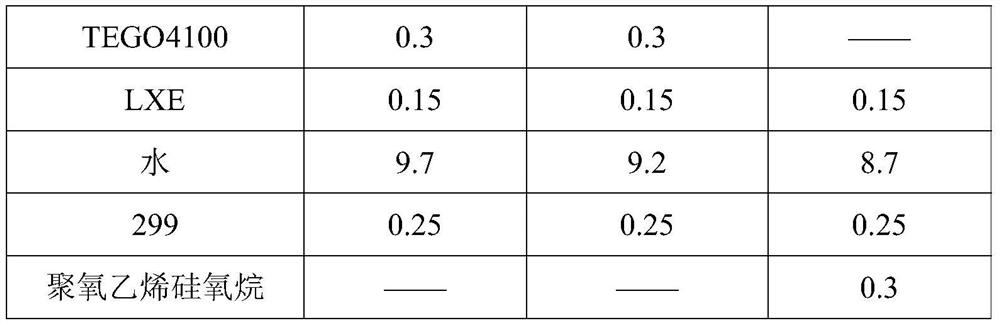

[0063] Embodiment 1~3 raw material ratio is as follows (weight ratio):

[0064]

[0065]

[0066] The preparation methods of Examples 1-3 are the same as those described above, wherein the polyoxyethylene siloxane is polymerized from 10 parts by weight of diethylene glycol and 50 parts by weight of vinyltrichlorosilane, and the preparation method is as follows:

[0067] Step 1: Mix 10 parts by weight of polyoxyethylene monomer with 10 parts by weight of silicone monomer, add 20 times by weight of triethylamine, add 5 times by weight of xylene, and reflux for 40 hours;

[0068] Step 2: Suction filter the mixture obtained in Step 1, remove the solid, spin dry, add the remaining silicone monomer, and react at 80 degrees Celsius for 72 hours;

[0069] Step 3: Take an equal weight of water to wash the mixture obtained in Step 2, and dry to obtain polyoxyethylene siloxane.

[0070] The preparation method of the polyoxyethylene siloxane of the embodiment of the present inventi...

Embodiment 4

[0085] Prepare primer and topcoat according to the water-based discoloration-resistant varnish component of Example 2, and mix the primer with water 1:1 to obtain the discoloration-resistant water-based discoloration-resistant varnish primer for African mahogany woodware for coating; African mahogany board Grind evenly, and apply the discoloration-resistant water-based primer for African mahogany woodware in the above-mentioned embodiment 2, dip-coat the above-mentioned polished African mahogany plank, dry it for 3 hours and then sand it to smooth and uniform, then spray the above-mentioned implementation The coating of Example 2 uses the discoloration-resistant water-based primer for African mahogany woodware, mixes water 1: (0-0.2), and adds 0.5wt% of water-based nano-iron oxide red-yellow paste, sprays evenly until the above-mentioned primer is done and polished On good panels, get primed panels. Spraying example 2 African mahogany woodware is finished twice with anti-disco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com