Radiating fin structure surface-mount rectifier bridge device

A technology of structural surface and rectifier bridge, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of large PCB board space, unfavorable energy saving and environmental protection, and large thickness, and achieve the effect of superior thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

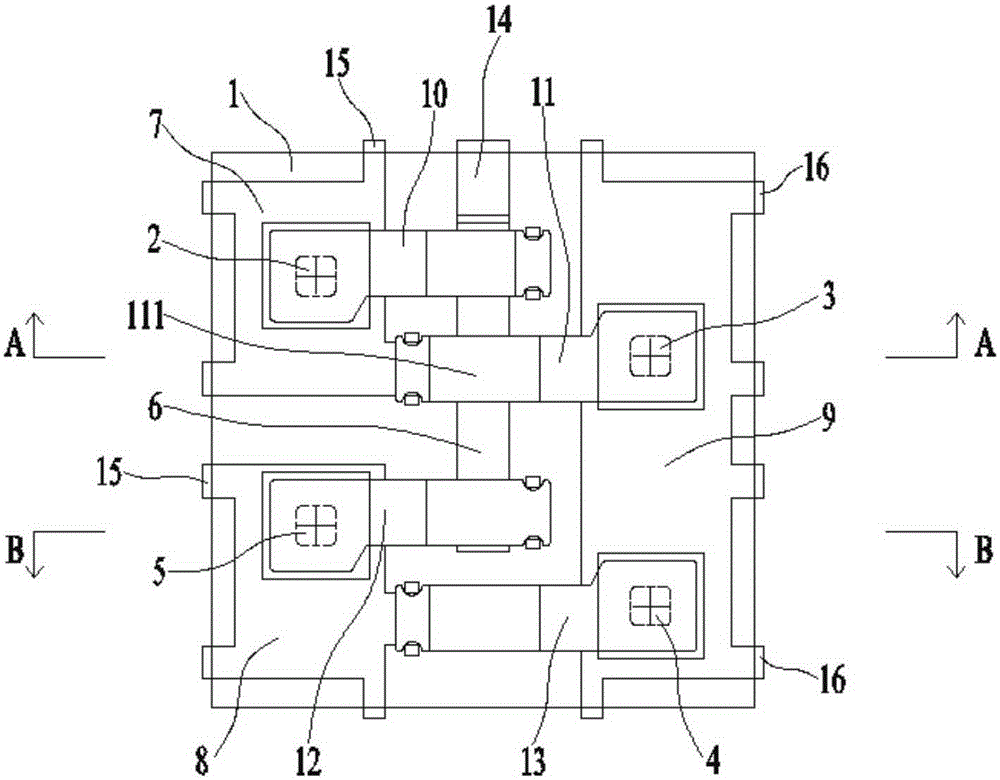

[0026] Embodiment: A heat sink structure surface mount rectifier bridge device, including: first, second, third, fourth diode chips 2, 3, 4, 5 and negative electrodes covered by epoxy package 1 Metal strip 6, the bottom of the epoxy package 1 and the first and second metal substrates 7, 8 and E-shaped metal substrate 9 are respectively fixed on the left and right sides, and the negative electrode metal strip 6 is located on the first, second, and second metal substrates. Between the second metal substrate 7,8 and the E-shaped metal substrate 9;

[0027] The positive terminal of the first diode chip 2 is electrically connected with the upper surface of the first metal substrate 7, the negative terminal of the second diode chip 3 is electrically connected with the upper surface of one end of the E-shaped metal substrate 9, and the third diode The negative end of the chip 4 is electrically connected to the upper surface of the other end of the E-shaped metal substrate 9, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com