Water pan and heat pump dryer comprising same

A water-receiving tray and dryer technology, applied in dryers, drying, refrigerators, etc., can solve the problems of loss of energy consumption of dryers, waste of condensed water cooling capacity, and excessive cooling capacity consumption, so as to improve the utilization rate of cooling capacity. , Improve heat exchange efficiency and enhance the effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

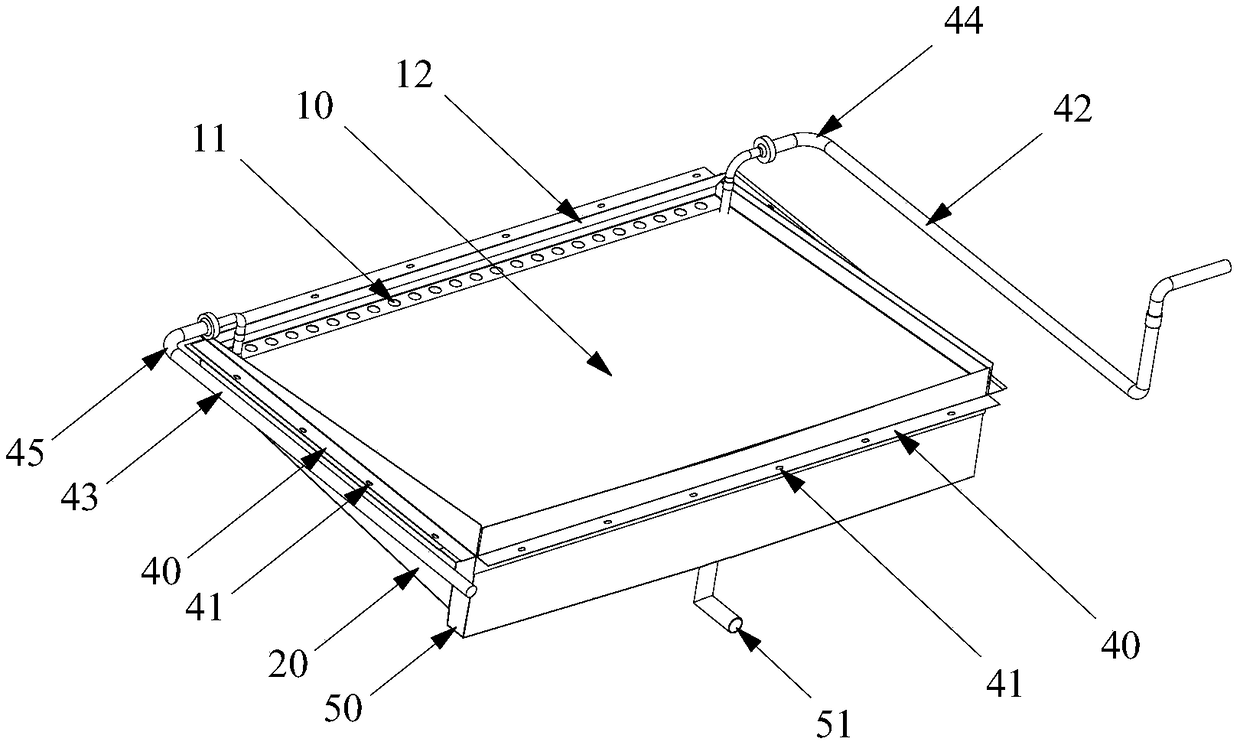

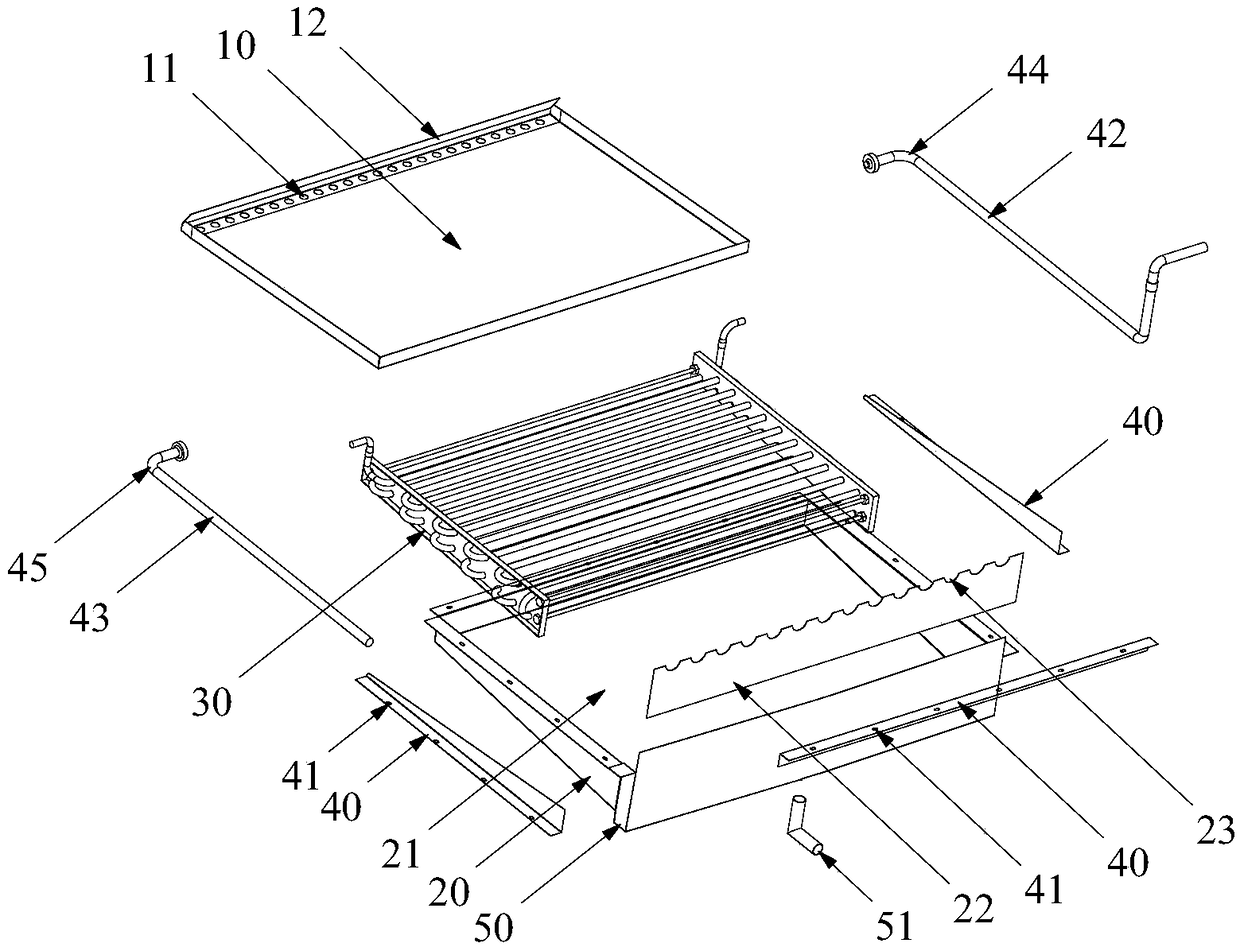

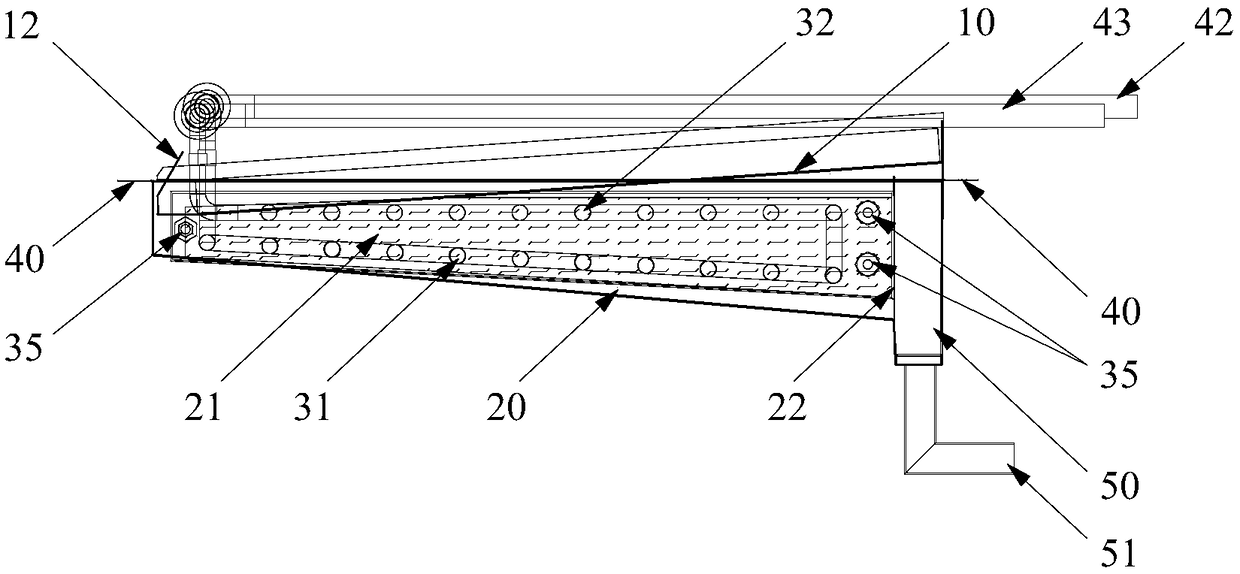

[0058] Such as Figure 1~Figure 3 As shown, a water receiving tray includes an upper tray 10 and a lower tray 20, and the upper tray 10 is located above the lower tray 20;

[0059] The upper plate 10 is used to receive the condensed water precipitated by the dryer, the rear end of the upper plate 10 is provided with a drain hole 11, and the bottom surface of the upper plate 10 is inclined downward towards the rear;

[0060] The lower plate 20 is used to receive the condensed water flowing out from the drain hole 11 , and the bottom surface of the lower plate 20 is inclined downward toward the front;

[0061] A cavity 21 for storing condensed water is formed inside the bottom wall 20 , and a heat exchange tube 30 is arranged in the cavity 21 .

[0062] After the condensed water separated out from the dryer is received by the upper plate 10 , it can flow smoothly to the drain hole 11 arranged at the rear end of the upper plate 10 along the bottom surface of the upper plate 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com