Sulfuric acid alkylation reaction method and device and heat removal method for sulfuric acid alkylation reaction

An alkylation reactor and a technology for the reaction, which are applied in the alkylation treatment, hydrocarbon oil treatment, petroleum industry, etc., can solve problems such as self-circulation, increase the ratio of alkene to olefin, reduce the amount of circulating light hydrocarbons, and reduce the effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

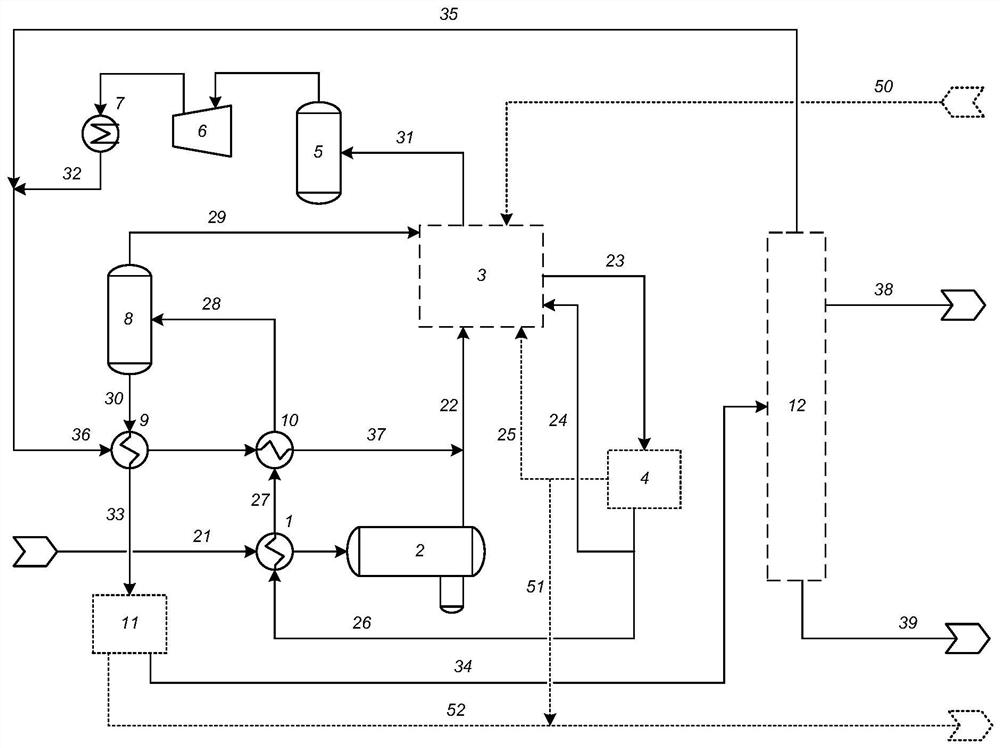

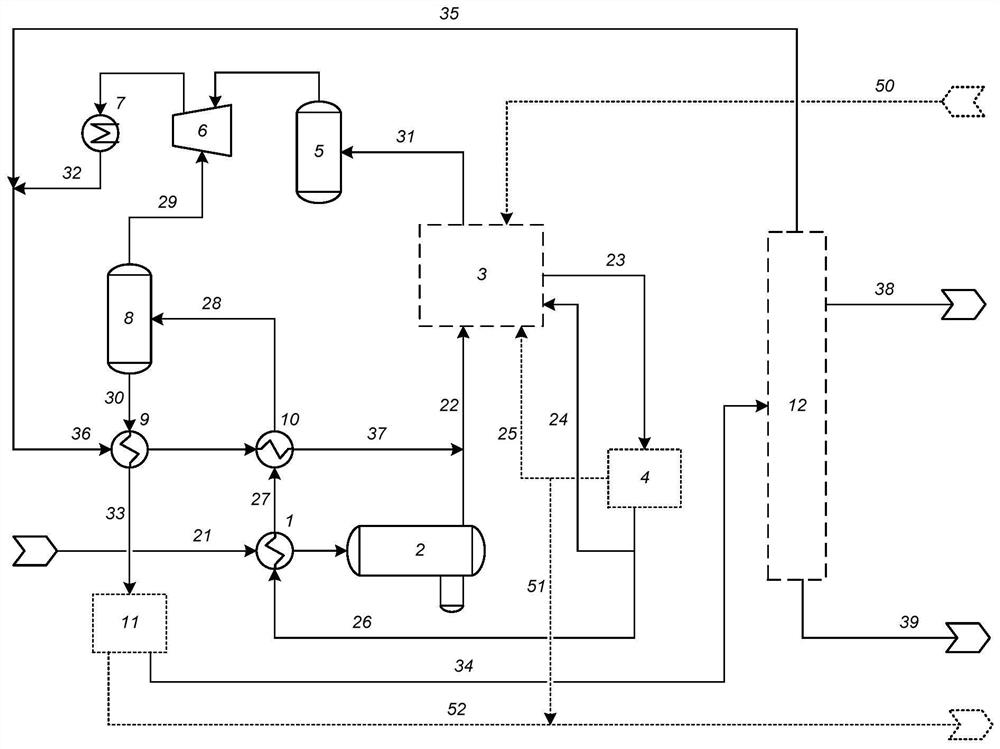

[0080] use figure 1 Shown sulfuric acid method alkylation reaction method and device, as figure 1 As shown, the C4 raw material passes through the pipeline 21 to exchange heat with the reaction product, then dehydrates in the dehydration tank 2, mixes with the circulating isobutane from the pipeline 37, and then enters the alkylation reactor 3. Under the action of sulfuric acid, the butene and isobutane in the feed react to generate alkylate, and the reaction liquid phase flows into the acid hydrocarbon primary separator 4 through the pipeline 23, and the separated sulfuric acid is recycled as a circulating acid; The crude reaction product is divided into two parts, one part is returned to the alkylation reactor through pipeline 24 as circulating hydrocarbon, and the other part enters the reaction product flash tank 8 through pipeline 28 after heat exchange, and the separated light hydrocarbon component is passed through The pipeline 29 returns to the primary inlet of the air...

Embodiment 2

[0085] The flow process of sulfuric acid alkylation reaction method is the same as embodiment 1.

[0086] Sulfuric Acid Alkylation Reaction Method C4 Feedstock B. See Table 2 for the main operating conditions of the alkylation reactor, Table 3 for the amount of circulating refrigerant treated by the compressor, and Table 4-1 and Table 4-2 for the processing capacity and product composition of the product separation unit. The product separation equipment includes a de-butanizer and a de-butanizer, and the main structural parameters are shown in Table 5. See Table 6 for public works material consumption.

Embodiment 3

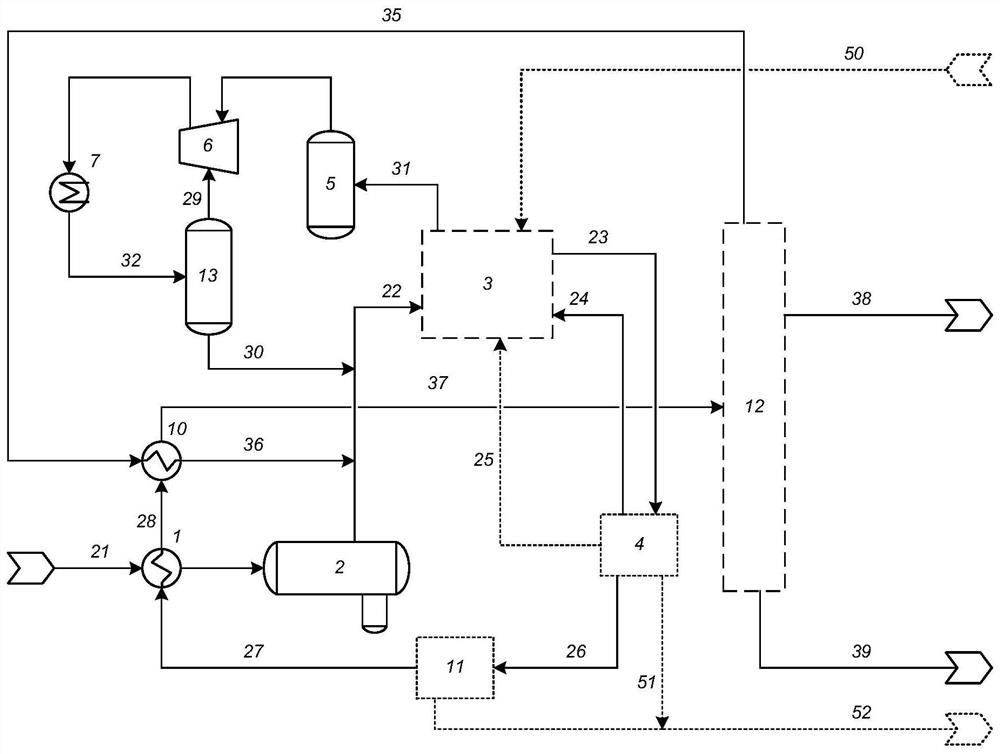

[0088] use figure 2 In the shown sulfuric acid alkylation reaction device and method, the air compressor system adopts a two-stage gas compression system. The difference from Embodiment 1 is that the crude reaction product enters the flash tank 8 for gas-liquid separation, and the separated light hydrocarbon components are directly returned to the secondary inlet of the compressor through the pipeline 29 .

[0089] For sulfuric acid alkylation reaction method C4 raw material A, see Table 2 for the main operating conditions of the alkylation reactor, see Table 3 for the amount of circulating refrigerant treated by the compressor, and see Table 4-1 for the processing capacity and product composition of the product fractionation unit. 4-2. The product separation equipment includes a de-butanizer and a de-butanizer, and the main structural parameters are shown in Table 5. See Table 6 for public works material consumption.

[0090] Table 1 C4 raw material composition

[0091] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com