Carrier of catalyst for light alkane dehydrogenation preparation of light olefin and use thereof

A technology of catalyst carrier and low-carbon olefins, applied in the direction of catalyst carrier, hydrocarbons, hydrocarbons, etc., can solve the problems of low loss of precious metals, loss of precious metals, poor wear resistance of dehydrogenation catalysts, etc., to reduce the loss of precious metals , enhance the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

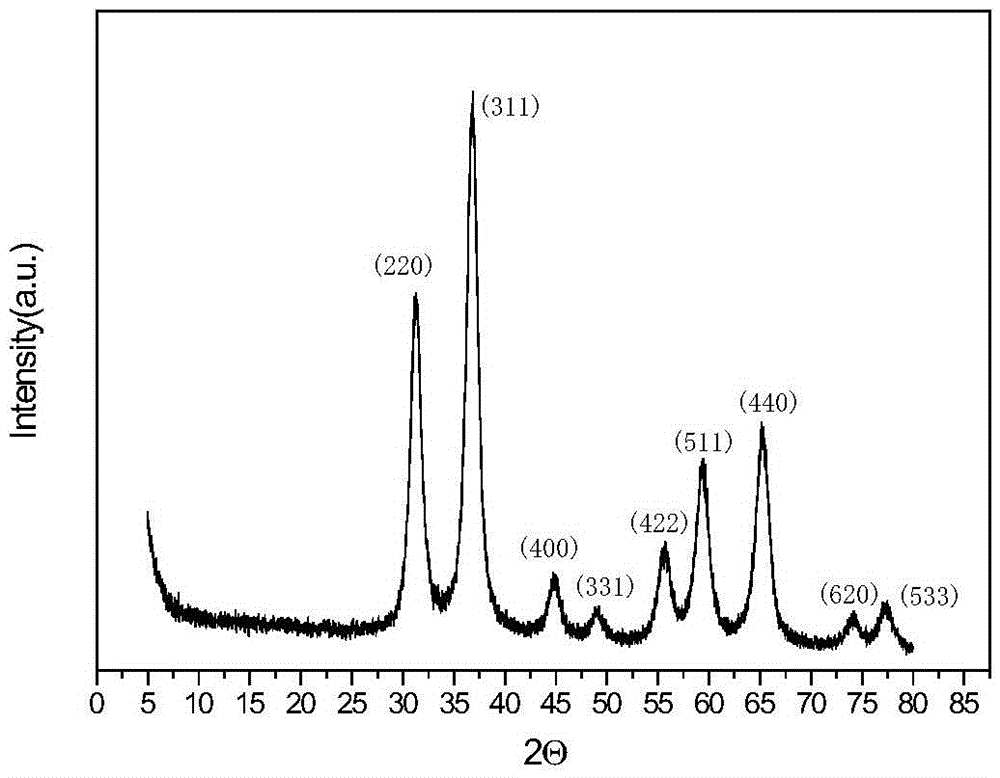

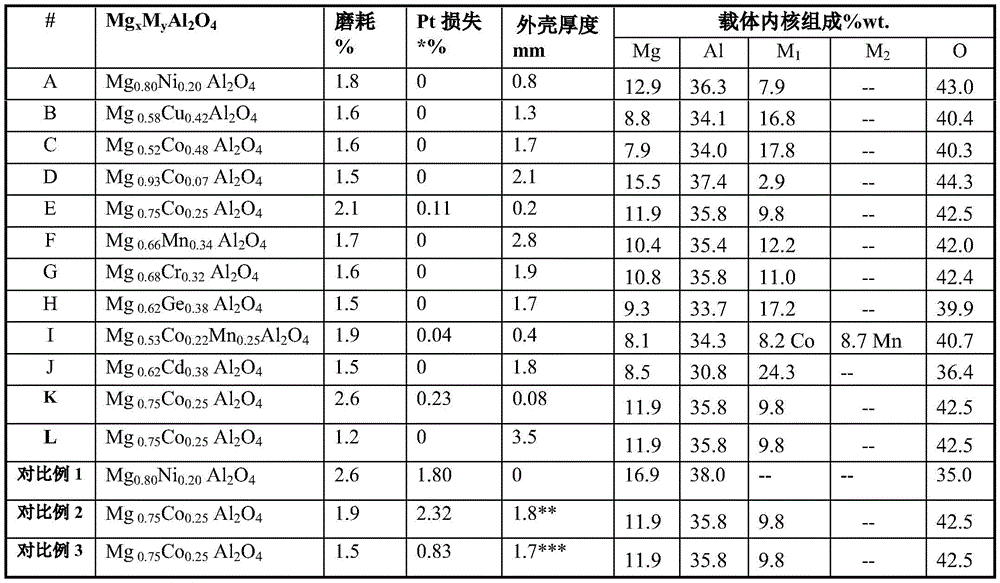

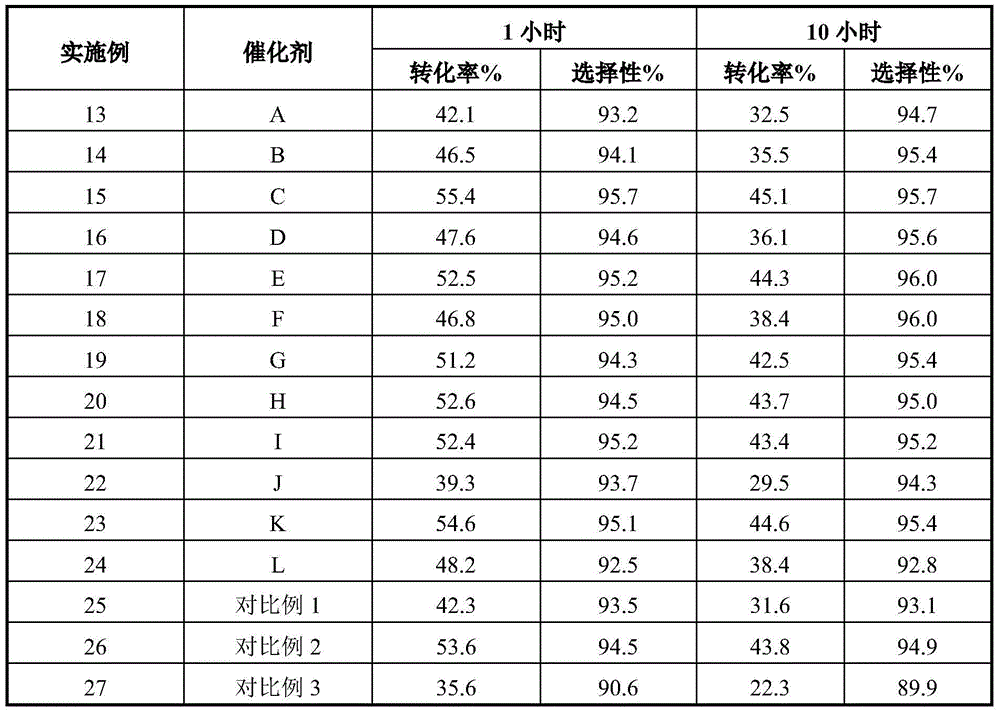

[0025] Get 751.56g aluminum nitrate (Al(NO 3 ) 3 9H 2 O), 205.12g magnesium nitrate (Mg(NO 3 ) 2 6H 2 O), 58.16g nickel nitrate (Ni(NO 3 ) 2 6H 2O) be dissolved in 2000ml deionized water; at 25 DEG C, under vigorous stirring, 6% by weight of ammonia water is slowly added dropwise to the mixed aqueous solution to form a precipitate, control the pH value to 6.7, and filter the precipitate at room temperature overnight , washed, extruded, dried at 80°C until the water content is about 10-30%, pelletized into cylindrical particles of Ф5×5mm, shaped into a spherical shape (diameter ~ 4mm) in a spherical granulator, and roasted at 720°C for 10 hours, a spherical carrier core was obtained. Roll the carrier evenly in a rolling ball equipment while spraying with 15% aluminum sol at room temperature. After 30 minutes, a composite carrier with a shell with a certain thickness is obtained. After drying at 120°C, bake at 1200°C for 8 hours to obtain a catalyst carrier. XRD charact...

Embodiment 2

[0029] Get 752.12g aluminum nitrate (Al(NO 3 ) 3 9H 2 O), 148.71g magnesium nitrate (Mg(NO 3 ) 2 6H 2 O), 101.47g copper nitrate (Cu(NO 3 ) 2 6H 2 O) be dissolved in 2000ml deionized water; at 20 DEG C, under vigorous stirring, 15% by weight of ammonia water is slowly added dropwise to the mixed aqueous solution to form a precipitate, control the pH value to 7.8, and filter the precipitate at room temperature overnight , washed, extruded, baked at 100°C until the water content is about 10-30%, pelletized into cylindrical particles of Ф5×5mm, shaped into a spherical shape (diameter ~ 4mm) in a spherical granulator, and roasted at 750°C for 8 Hours, the inner core of the composite magnesium aluminate carrier was obtained. The carrier is evenly rolled in the rolling ball equipment and sprayed with 20% aluminum sol at 40°C. After 30 minutes, a composite carrier with a shell with a certain thickness is obtained. After drying at 120°C, it is baked at 1100°C for 12 hours to o...

Embodiment 3

[0033] Get 751.36g aluminum nitrate (Al(NO 3 ) 3 9H 2 O), 133.33g magnesium nitrate (Mg(NO 3 ) 2 6H 2 O), 139.26g cobalt nitrate (Co(NO 3 ) 2 6H 2 O) be dissolved in 2000ml deionized water; at 26°C, under vigorous stirring, 20% by weight of ammonia water is slowly added dropwise to the mixed aqueous solution to form a precipitate, control the pH value to 7.2, and filter the precipitate after overnight at room temperature , washed, extruded, baked at 120°C until the water content is about 10-30%, pelletized into cylindrical particles of Ф5×5mm, shaped into a spherical shape (diameter ~ 4mm) in a spherical granulator, and roasted at 800°C for 5 Hours, the inner core of the composite magnesium aluminate carrier was obtained. The carrier is evenly rolled in the rolling ball equipment and sprayed with 25% aluminum sol at 40°C. After 30 minutes, a composite carrier with a shell with a certain thickness is obtained. After drying at 120°C, it is roasted at 1200°C for 8 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com