Hot start method for boost expander

An expander, hot start technology, applied in lighting and heating equipment, liquefaction, solidification and other directions, can solve the problems of high power consumption and cooling efficiency discount, and achieve the effect of reducing start-up power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

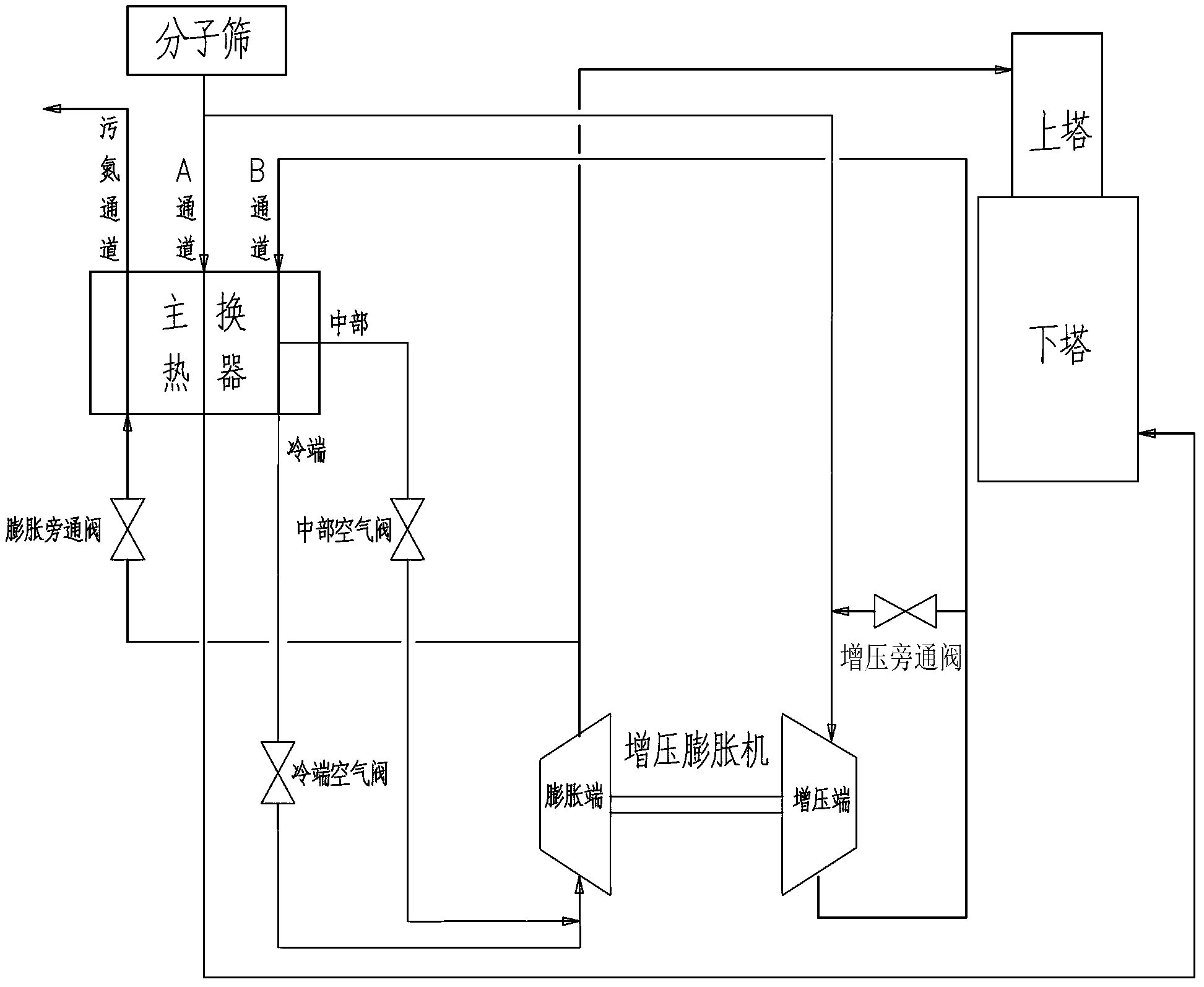

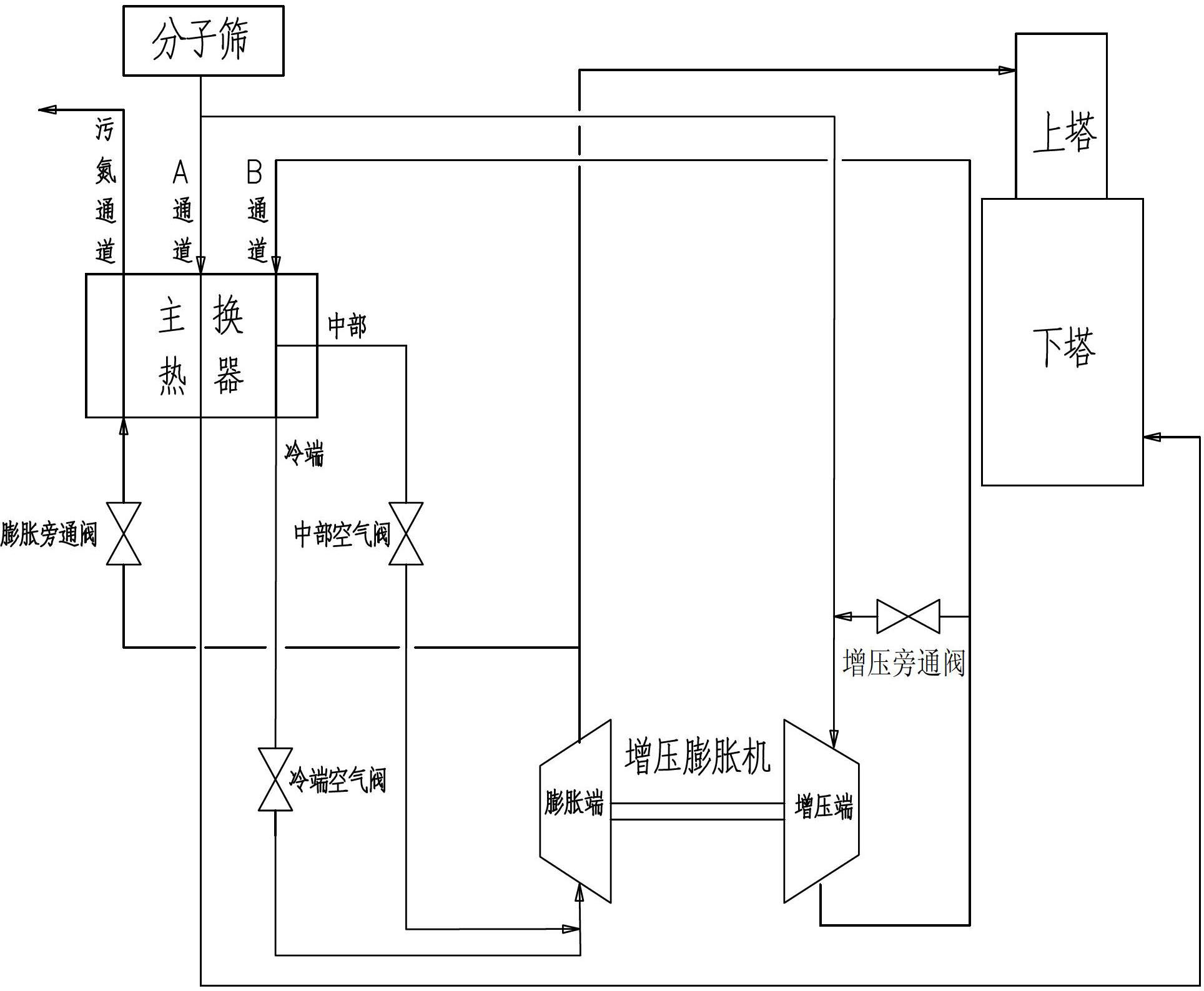

[0017] See figure 1 , is a process flow diagram of an embodiment of a method for thermally starting a booster expander in the present invention. In the initial stage of thermally starting the expander, in the present invention, all the gas at the outlet of the expansion end is bypassed with the dirty nitrogen channel of the main heat exchanger to speed up the main heat exchanger. At the same time, the air at the outlet of the cold end of the main heat exchanger is first introduced into the expansion end, and after the temperature of the outlet air at the expansion end drops to the design value, the air in the middle of the main heat exchanger is gradually introduced into the expansion end. Make full use of the maximum cooling capacity to shorten the hot start-up time of the air separation unit, and make the expander always operate at the highest d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com