Energy-saving and environment-friendly method for preparing ethylbenzene from dry gas

An energy-saving, environmentally friendly, dry gas technology, applied in chemical instruments and methods, including molecular sieve catalysts, hydrocarbons, etc., can solve the problem of not giving the recovery rate of benzene carried by the tail gas, save equipment investment and follow-up operation costs, reduce The effect of device energy consumption and equipment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

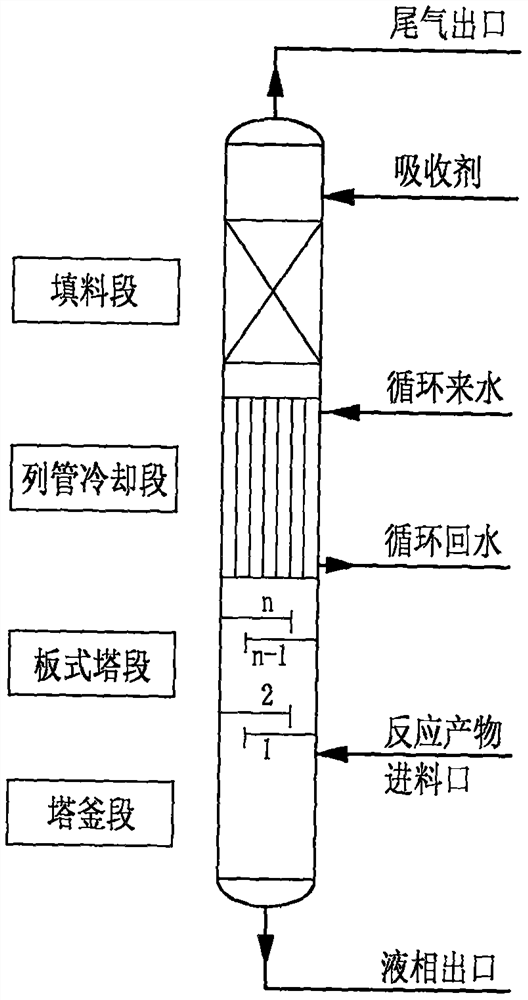

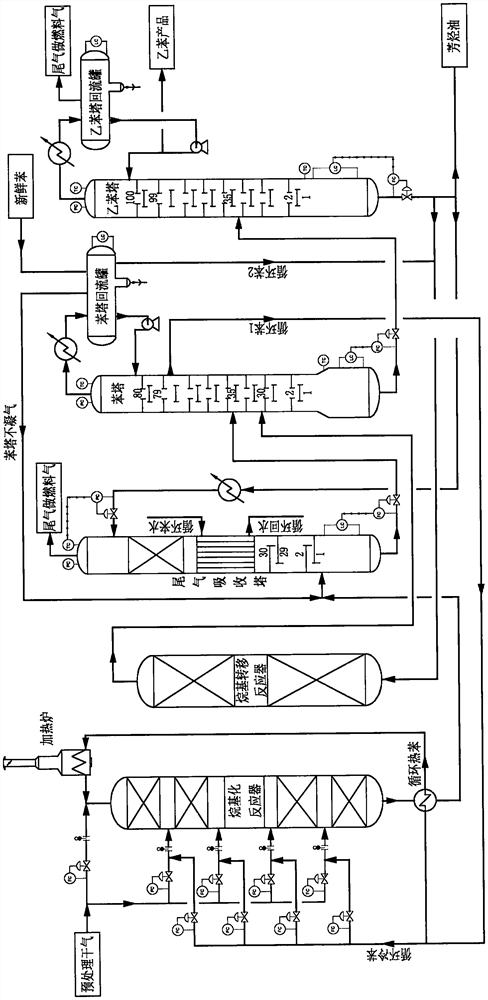

[0066] This example uses figure 1 The absorption separation tower shown and figure 2 The process flow shown is carried out on an 80,000-ton / year dry gas-to-ethylbenzene plant in a factory in Hami, Xinjiang.

[0067] After the raw MTP dry gas is pretreated to remove propylene, it enters the alkylation reactor in stages. The circulating hot benzene withdrawn from the upper part of the benzene tower enters from the top of the reactor, the feed temperature is 360°C, and the pressure is 1.0MPa. The circulating cold benzene extracted from the upper section of the benzene tower enters between the catalyst beds, the feed temperature is 200°C, and the pressure is 1.2MPa. The alkylation reaction temperature is 360-400°C, the reaction pressure is 1.0MPa, the weight ratio of benzene to ethylene is 15, and the weight hourly space velocity of ethylene is 0.8h -1 .

[0068] After the alkylation reaction product exchanges heat with the circulating benzene 1 extracted from the upper section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com