Miniature bridge rectifier

A rectifier and micro-bridge technology, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of device damage, large thickness, and large space on PCB boards, and achieve improved installation accuracy and good heat conduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

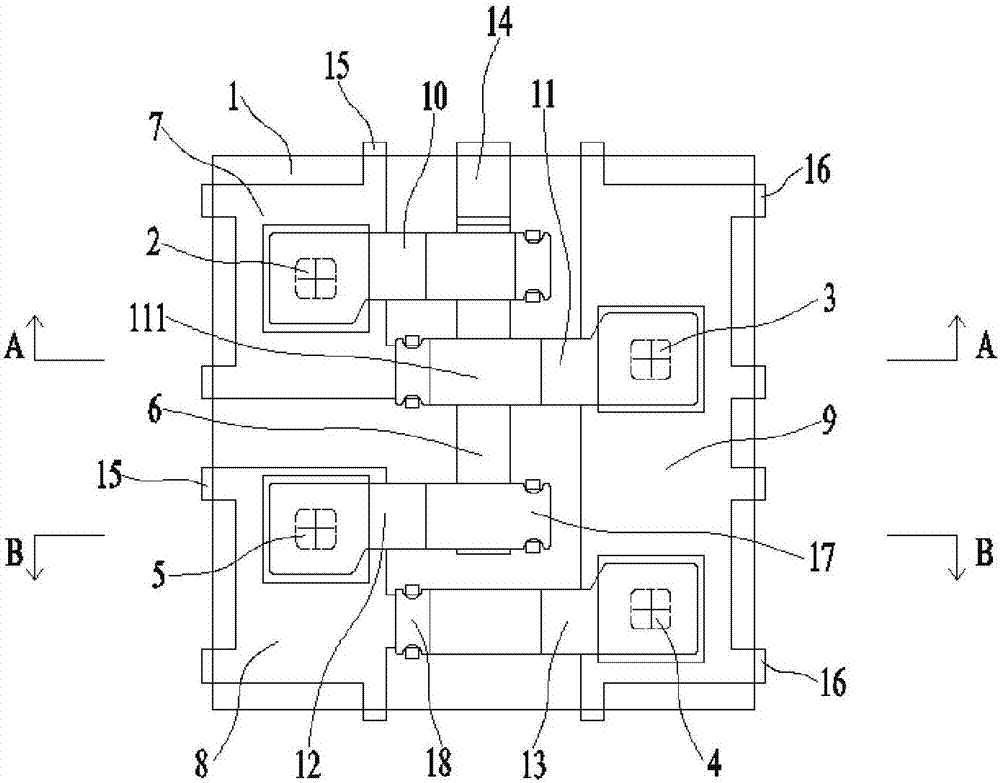

[0025] Embodiment: A kind of miniature bridge stack rectifier, comprising: first, second, third, fourth diode chips 2, 3, 4, 5 and negative electrode metal strip 6 covered by epoxy encapsulation body 1, The bottom of the epoxy package 1 and the left and right sides are respectively fixed with first and second metal substrates 7 and 8 and an E-shaped metal substrate 9, and the negative electrode metal strip 6 is located on the first and second metal substrates. Between 7,8 and the E-shaped metal substrate 9;

[0026] The positive terminal of the first diode chip 2 is electrically connected with the upper surface of the first metal substrate 7, the negative terminal of the second diode chip 3 is electrically connected with the upper surface of one end of the E-shaped metal substrate 9, and the third diode The negative end of the chip 4 is electrically connected to the upper surface of the other end of the E-shaped metal substrate 9, and the positive end of the fourth diode chip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com