Microbiological fuel cell and recycling method for cassava waste mash

A fuel cell and microorganism technology, which is applied in the fields of environmental protection and comprehensive utilization of resources, can solve the problems that it is difficult to effectively realize the recycling of cassava waste mash, the waste mash is not directly utilized, etc., so as to improve the effect of electricity production and improve the degradability. , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

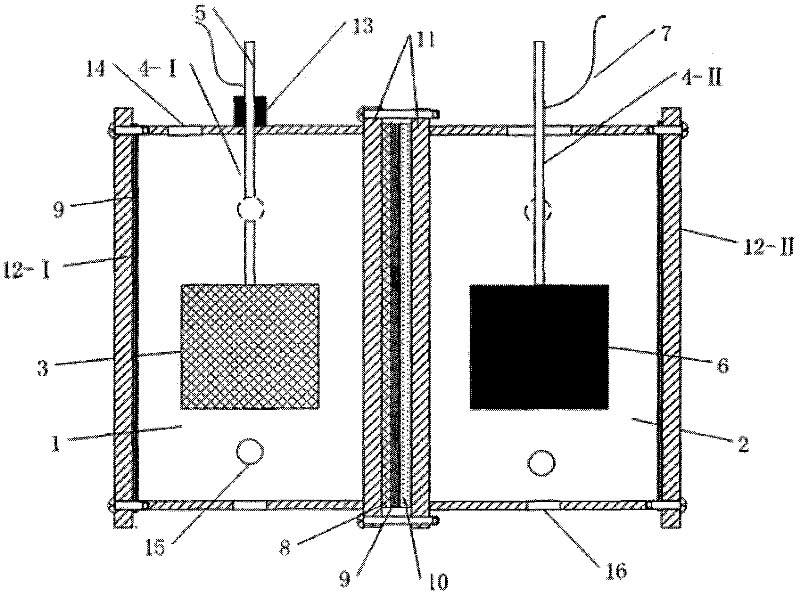

[0011] Specific embodiment 1: Structure of microbial fuel cell

[0012] The microbial fuel cell used in this embodiment (see figure 1 ) Consists of anode chamber 1, cathode chamber 2, anode 3, graphite rod (or titanium wire) 4, anode wire 5, catalytic cathode 6, cathode wire 7, isolation material 8, silica gel gasket 9, cation exchange membrane 10, flange 11. Sealing cover 12, characterized in that the anode chamber 1 and cathode chamber 2 of the microbial fuel cell are both closed-head cubic structures and symmetrically distributed. The two electrode chambers are connected by flange 11, with cation exchange membrane 10 and silica gel in between. The gasket 9 and the isolation material 8 are all rectangular. The center of the gasket has a rectangular square hole. The side length of the hole is smaller than the side length of the membrane. The isolation material 8, the gasket 9, the membrane 10 are arranged in order to form the membrane module , Connected and fixed with flange 11 ...

specific Embodiment approach 2

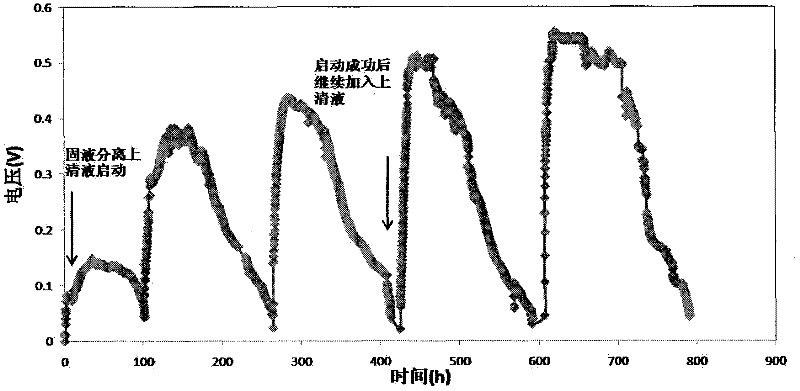

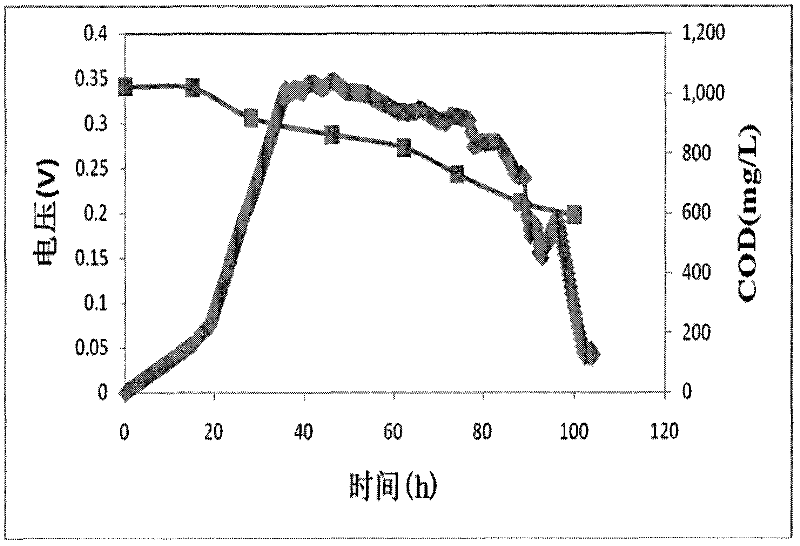

[0018] Specific embodiment two: using microbial fuel cell to dispose of waste mash

[0019] In this embodiment, the microbial fuel cell device described in the first embodiment uses cassava waste mash as a substrate to generate electricity, so that the waste mash is practically feasible. In the following examples, some typical conditions are provided And the structure is used to illustrate the present invention, but does not limit the scope of the present invention. The specific steps are as follows:

[0020] (1) Solid-liquid separation of waste mash: use centrifugal separation to process cassava waste mash to obtain mash and supernatant at 5000~8000rpm for 8~10min, take the supernatant and use medium-speed qualitative filter paper for use;

[0021] (2) Ultrasonic-high-temperature anaerobic short-path fermentation combined treatment: Collect the mash in step 1 in a centrifuge tube, and use an ultrasonic cell disruptor to break it. The ultrasonic power density is 1~1.5W / ml, the freque...

specific Embodiment approach 3

[0025] Specific embodiment three: This embodiment is different from the ultrasonic processing method described in step 2 of the second embodiment in that the ultrasonic power density is 1.5 W / mL and the frequency is 20 kHz. The other embodiments are the same as the first and second specific embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com