Method for directly preparing catalytic layer of platinum monoatomic layer used for proton exchange membrane fuel cell

A technology of proton exchange membrane and single atomic layer, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of unfavorable mass transfer, poor battery performance, and inability to ensure uniformity, and achieve the effect of improving utilization

Inactive Publication Date: 2018-05-25

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF3 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantages of the traditional method of preparing membrane electrodes: the carbon-supported catalyst and the electrolyte components are randomly mixed, and their uniformity cannot be guaranteed, and the three-phase interface of protons, electrons, and gases cannot be effectively constructed. The pores of the catalytic layer are relatively dense, which is not conducive to mass transfer. Battery performance is poor at lower loads

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0029] The difference from Example 1 is that the prepared Pd loading is 0.3 mg cm -2 the catalytic layer.

Embodiment 3

[0031] The difference from Example 1 is that the underpotential deposition technique can be continued on the single-layer platinum surface to prepare a multi-atomic layer platinum catalytic layer, and the Pt loadings of 0.05 and 0.06 mg cm can be obtained respectively. -2 gas diffusion electrodes.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

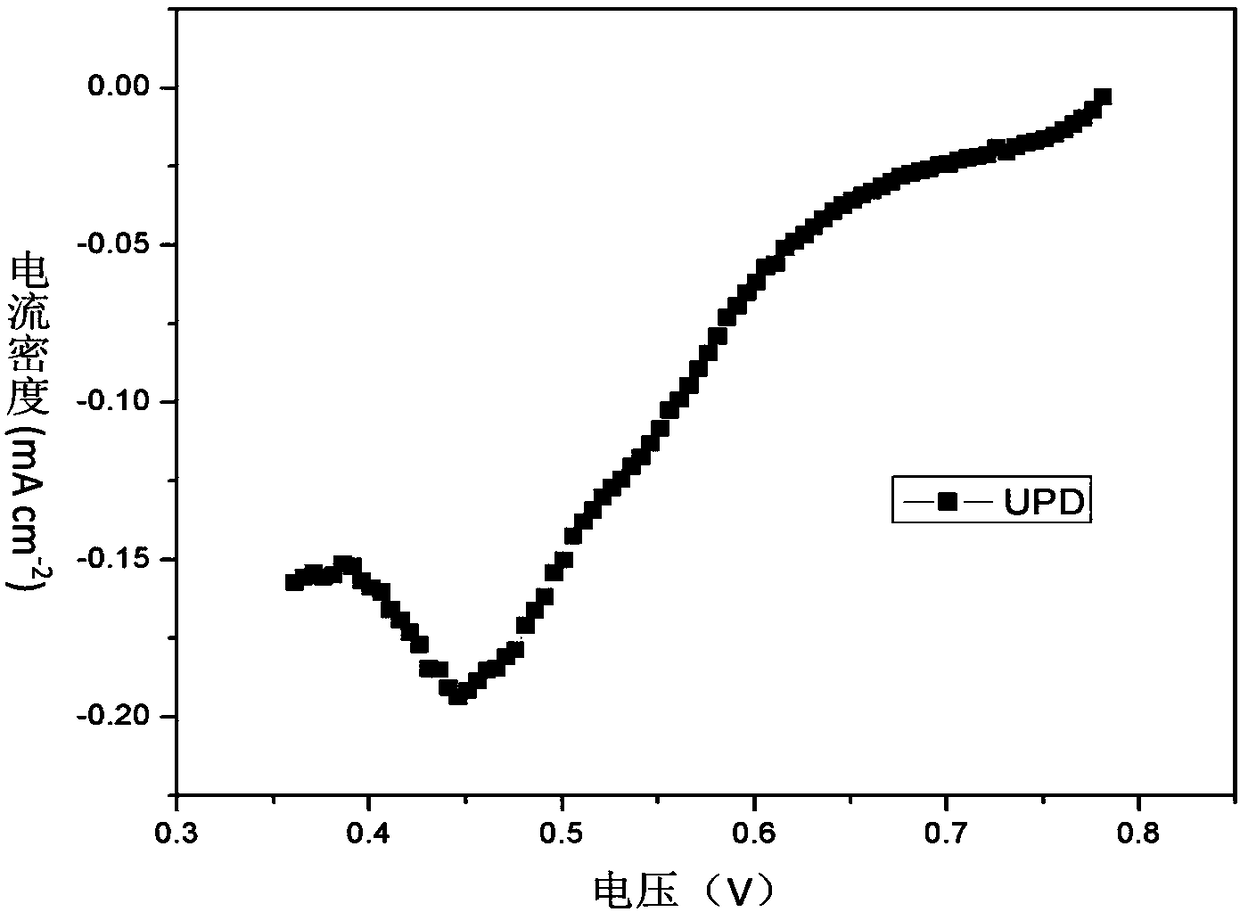

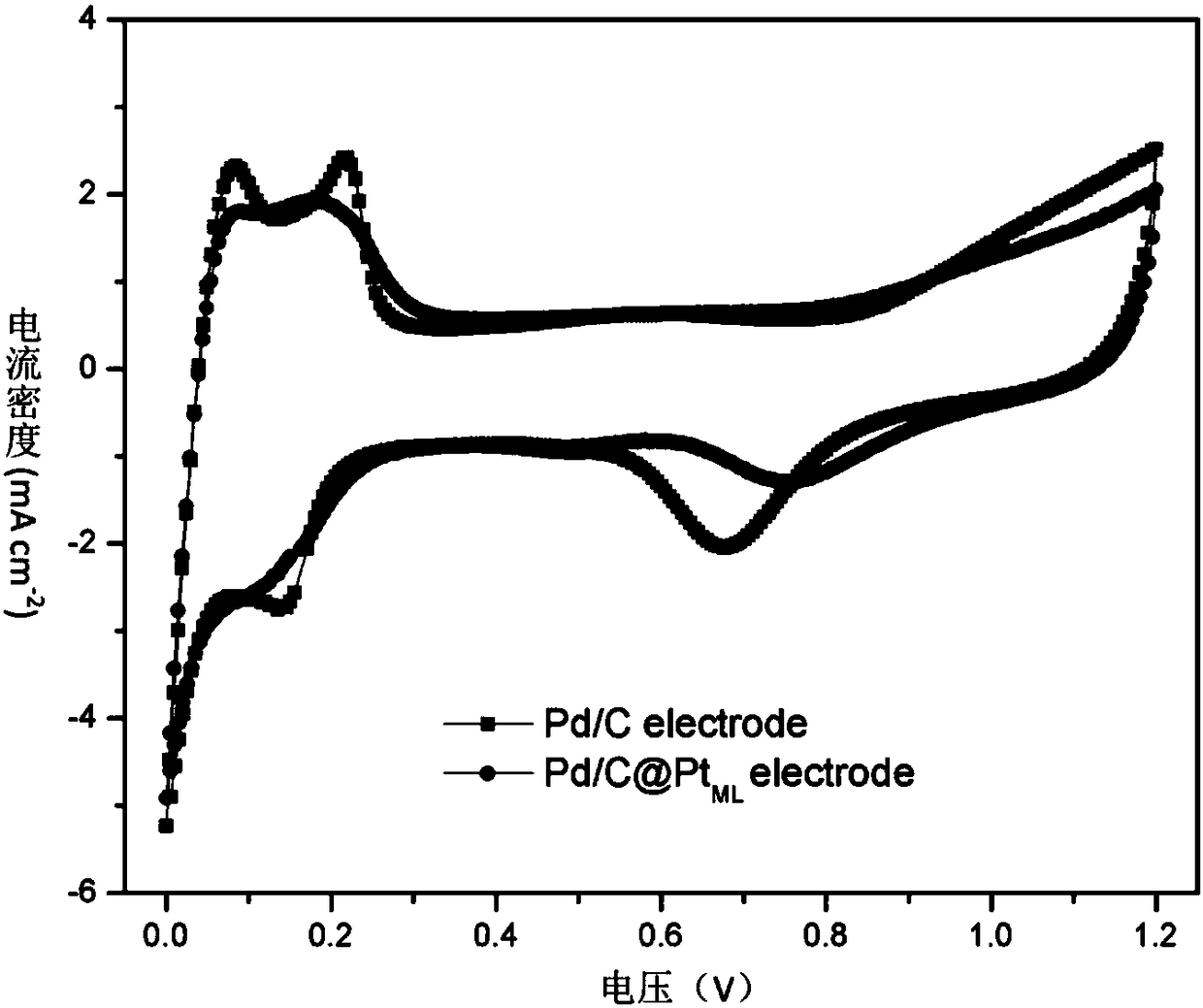

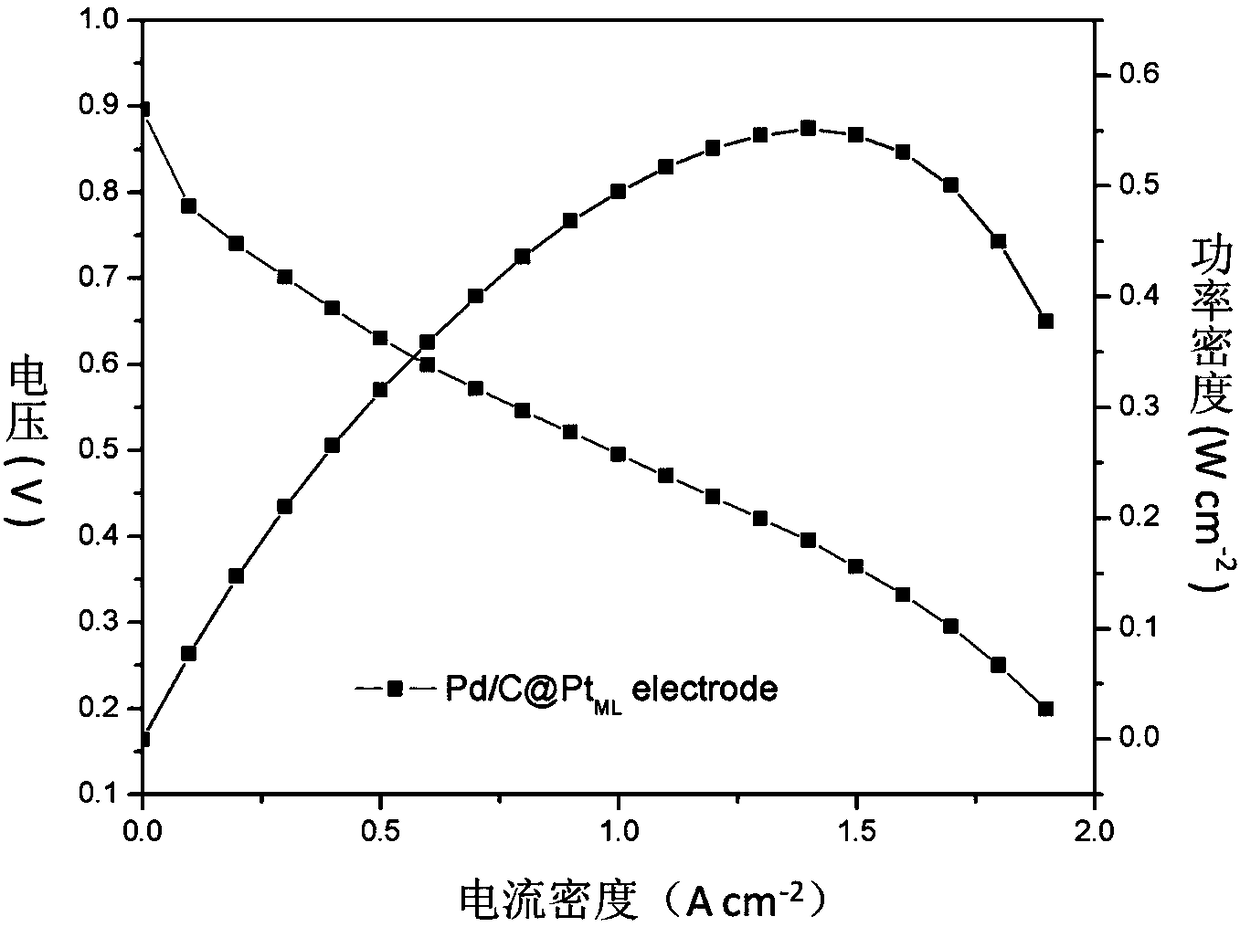

The invention discloses a method for directly preparing a catalytic layer of a platinum monoatomic layer used for a proton exchange membrane fuel cell. The method comprises the following steps of directly preparing a Pd / C catalytic layer in advance by using the catalytic layer through electrospinning technique, selecting polymer such as polyacrylic acid as a binder, afterwards, in a three-electrode system, adopting an underpotential deposition method to deposit Cu of a monoatomic layer on the Pd / C catalytic layer, then performing replacement to obtain the Pt of the monoatomic layer, and finally preparing a Pd / C@PtML catalytic layer. The Pd / C@PtML catalytic layer serves as a cathode, the Pd loading is 0.15mg / cm<-2>, the Pt loading is 0.02mg / cm<-2>, the maximum power density of a single cellis 560mW / cm<-2> (H2-Air), so that the Pd / C@PtML catalytic layer is superior to a catalytic layer of which the cathode Pt loading is 0.09mg / cm<-2>. By carrying out single cell acceleration attenuationtests on two catalytic layers, the Pd / C@PtML catalytic layer can be found to have better stability.

Description

technical field [0001] The invention belongs to the field of fuel cells and relates to a method for directly preparing a platinum monoatomic layer catalytic layer for a proton exchange membrane fuel cell. Background technique [0002] Proton exchange membrane fuel cell (PEMFC) has the advantages of high power density, high energy conversion efficiency, low temperature start-up, and environmental friendliness, and is considered as an ideal power source for stationary power stations, electric vehicles, and portable power sources. Then, if it wants to be successfully commercialized, it mainly faces two problems of cost and lifespan. In the fuel cell components, the cost of the catalyst accounts for nearly half, and reducing the catalyst load is the most direct way to reduce the cost of the fuel cell. Therefore, the preparation of highly active catalysts and the optimization of the electrode preparation process to enable low-load catalysts to still have high catalytic performan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/88H01M4/92

CPCH01M4/8878H01M4/92Y02E60/50

Inventor 侯明洪绍景邵志刚衣宝廉

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com