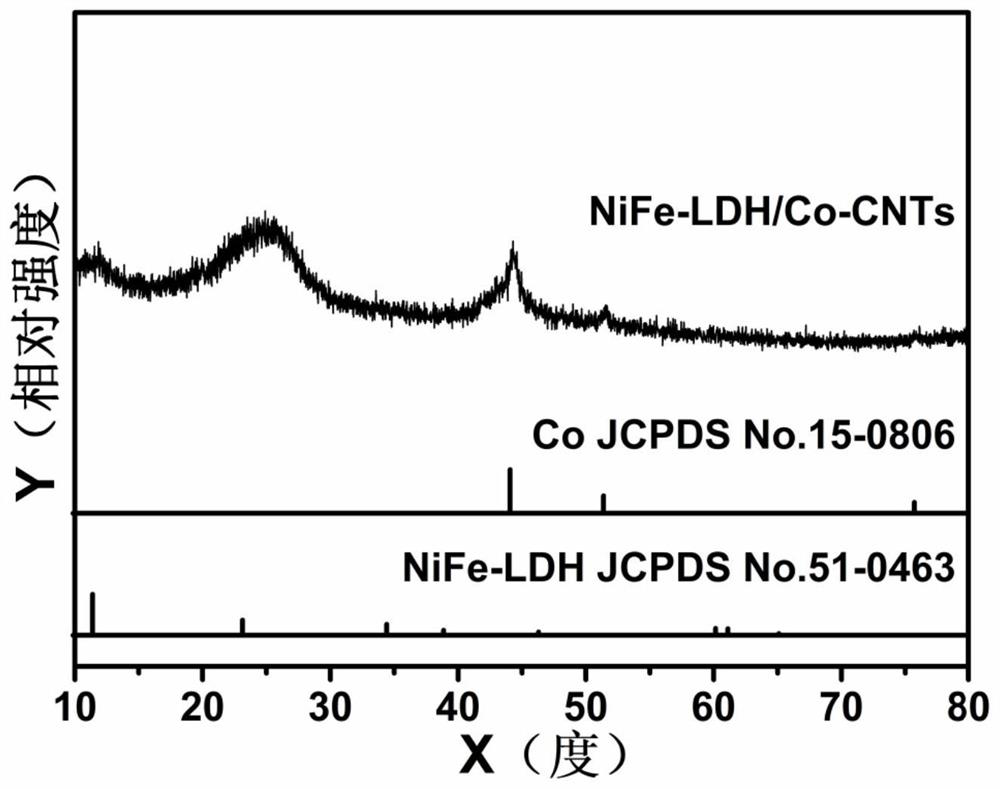

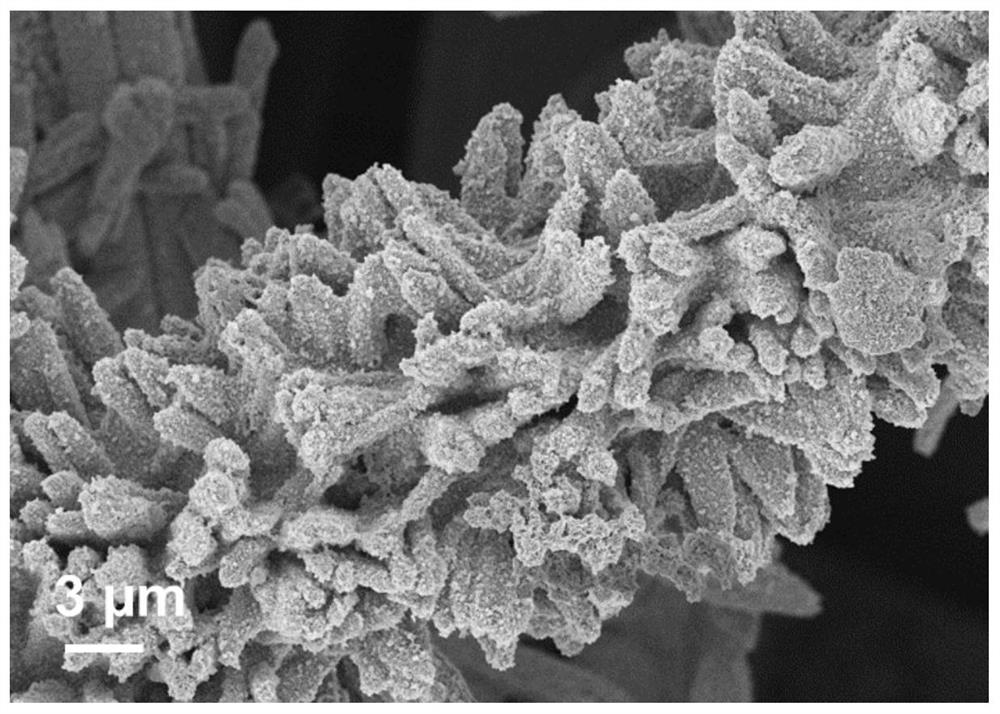

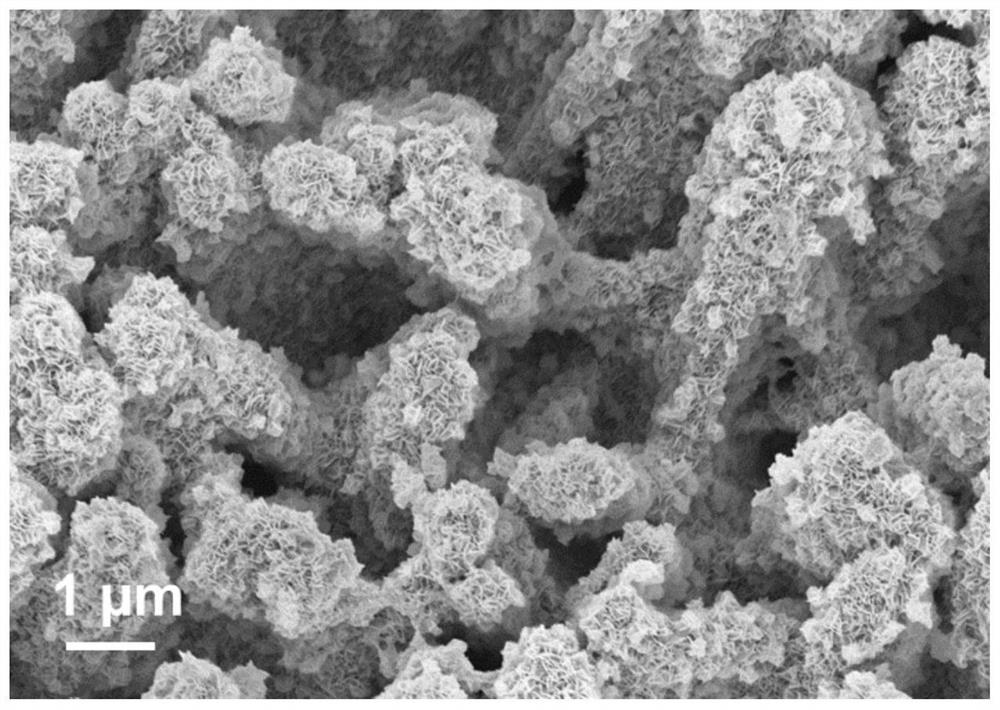

NiFe-LDH/Co-CNTs nano composite material and preparation method and application thereof

A nanocomposite material and nanomaterial technology, applied in the field of NiFe-LDH/Co-CNTs nanocomposite material and its preparation, can solve the problems of insufficient zinc-air battery performance, high bifunctional activity, etc., and achieve high energy conversion efficiency and cycle Stability, high bifunctional activity, effect of increasing power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Treatment of carbon cloth (CC)

[0040] Immerse the carbon cloth in acetone solution and ultrasonicate it for 15 minutes, wash it several times with absolute ethanol and deionized water after the ultrasonic treatment, and then immerse the carbon cloth in concentrated nitric acid (HNO 3 ), stirred in a water bath at 60°C for 2 hours, and finally washed several times with absolute ethanol and deionized water, and set aside.

[0041] (2) Preparation of Co-ZIF / CC

[0042] 0.582g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) Dissolve in 40mL of deionized water, pour it into 40mL of deionized water in which 1.32g 2-methylimidazole (2-MIM) has been dissolved, and after ultrasonic mixing at room temperature, the treated carbon cloth (CC) Add it into the formed purple solution, and age it for 4 hours after being fully submerged. Take out the carbon cloth with Co-ZIF grown on it, rinse it with deionized water several times, and dry it at 80°C for 6 hours.

[0043] (3) Preparation...

Embodiment 2

[0056] (1) Treatment of carbon cloth (CC)

[0057] Immerse the carbon cloth in acetone solution and ultrasonicate it for 15 minutes, wash it several times with absolute ethanol and deionized water after the ultrasonic treatment, and then immerse the carbon cloth in concentrated nitric acid (HNO 3 ), stirred in a water bath at 60°C for 2 hours, and finally washed several times with absolute ethanol and deionized water, and set aside.

[0058] (2) Preparation of Co-ZIF / CC

[0059] 0.582g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) Dissolve in 40mL of deionized water, pour it into 40mL of deionized water in which 1.32g 2-methylimidazole (2-MIM) has been dissolved, and after ultrasonic mixing at room temperature, the treated carbon cloth (CC) Add it into the formed purple solution, and age it for 4 hours after being fully submerged. Take out the carbon cloth with Co-ZIF grown on it, rinse it with deionized water several times, and dry it at 80°C for 6 hours.

[0060] (3) Preparation...

Embodiment 3

[0065] (1) Treatment of carbon cloth (CC)

[0066] Immerse the carbon cloth in acetone solution and ultrasonicate it for 15 minutes, wash it several times with absolute ethanol and deionized water after the ultrasonic treatment, and then immerse the carbon cloth in concentrated nitric acid (HNO 3 ), stirred in a water bath at 60°C for 2 hours, and finally washed several times with absolute ethanol and deionized water, and set aside.

[0067] (2) Preparation of Co-ZIF / CC

[0068] 0.582g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) Dissolve in 40mL of deionized water, pour it into 40mL of deionized water in which 1.32g 2-methylimidazole (2-MIM) has been dissolved, and after ultrasonic mixing at room temperature, the treated carbon cloth (CC) Add it into the formed purple solution, and age it for 4 hours after being fully submerged. Take out the carbon cloth with Co-ZIF grown on it, rinse it with deionized water several times, and dry it at 80°C for 6 hours.

[0069] (3) Preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum power density | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com