Method for manufacturing supercapacitor material by coating MOF (metal organic frame) with dopamine

A supercapacitor and dopamine technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of poor stability and insufficient electrochemical activity, and achieve the effects of good performance, easy promotion and excellent electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] As introduced in the background art, the current supercapacitor materials still have the problems of insufficient electrochemical activity and poor stability in an alkaline environment. Therefore, the present invention proposes a method for making supercapacitor materials by coating MOF with dopamine. Using bimetallic MOF as a template and raw material, after dopamine-coated vulcanization, it becomes a stable hollow structure Zn x co 1-x S@C (x=0.01~1.0), as a high-performance supercapacitor cathode material, the specific preparation method includes the following steps:

[0037] a. Preparation of ZnCo-MOF precursor at room temperature;

[0038] b. Disperse the prepared ZnCo-MOF in the solution for dopamine coating;

[0039] c. Collect the coated product for annealing treatment;

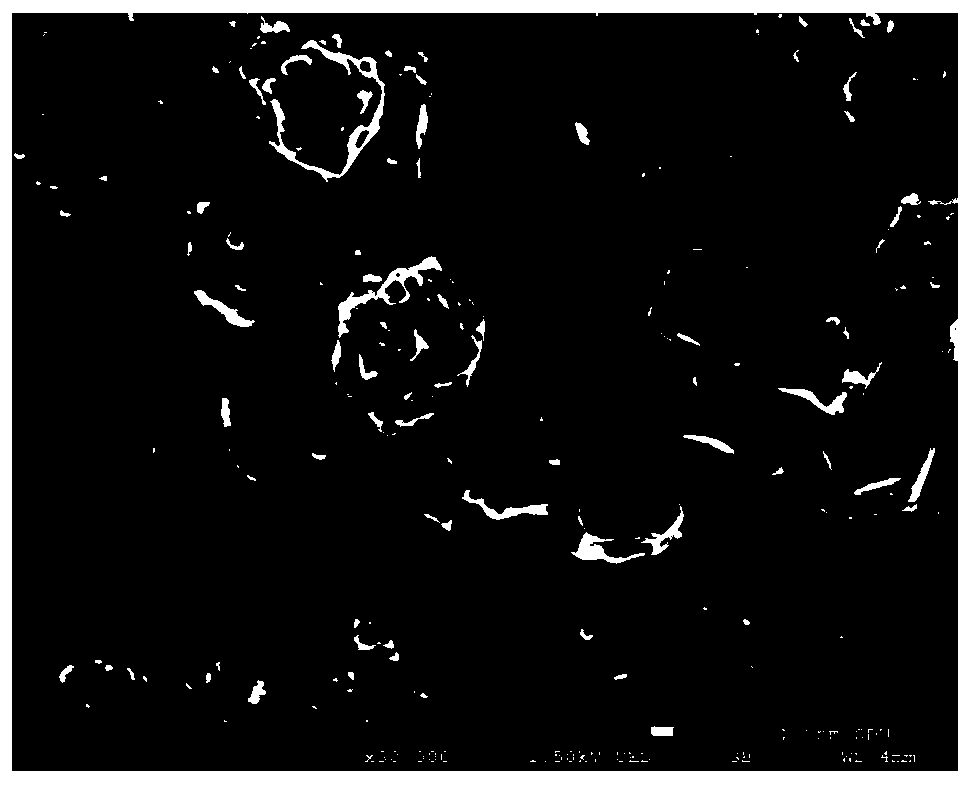

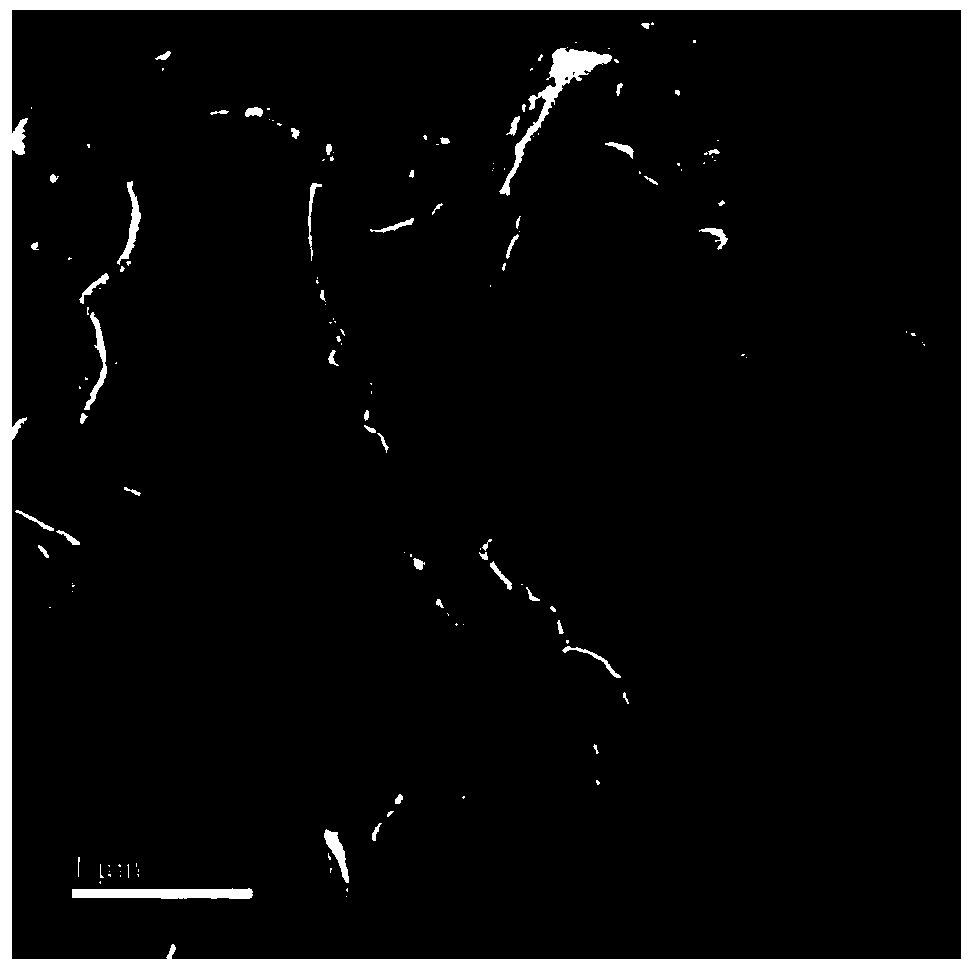

[0040] d. Sulfurize the annealed product to obtain Zn x co 1-x S@C (x=0.01~1.0) hollow structure.

[0041] The specific steps for preparing the ZnCo-MOF precursor at room temperature des...

Embodiment 1

[0052] Add 0.291 g of cobalt nitrate hexahydrate and 0.595 g of zinc nitrate hexahydrate into 25 mL of methanol, and stir to form a uniform solution. Add 0.985 g of dimethylimidazole into 15 mL of methanol and stir to form a homogeneous solution. The methanol solution of dimethylimidazole was added dropwise to the nitrate solution and stirred continuously to form a homogeneous solution and then left to stand for 24 hours to obtain a precipitate; the precipitate was collected by centrifugation and washed three times with methanol to obtain the ZIF-8 precursor.

[0053] 130 mg of ZnCo-MOF precursor was added to 100 mL of Tris-HCL buffer (PH=8.5) containing 100 mg of dopamine, and stirred for 24 h after ultrasonication for 2 minutes. The precipitate was collected by centrifugation, washed with deionized water and ethanol in turn, and dried at 60° C. for 5 hours. The dried ZnCo-MOF@PDA polyhedron was heated to 600°C at a rate of 5°C per minute under the protection of nitrogen and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com