Preparation method of lithium ion capacitor (LIC) adopting pre-lithiation hard carbon negative electrode

A capacitor and lithium ion technology, applied in the field of lithium ion capacitors, can solve the problems of small stored energy and high energy storage speed, and achieve the effects of small impedance, simple operation and small diffusion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below through specific examples.

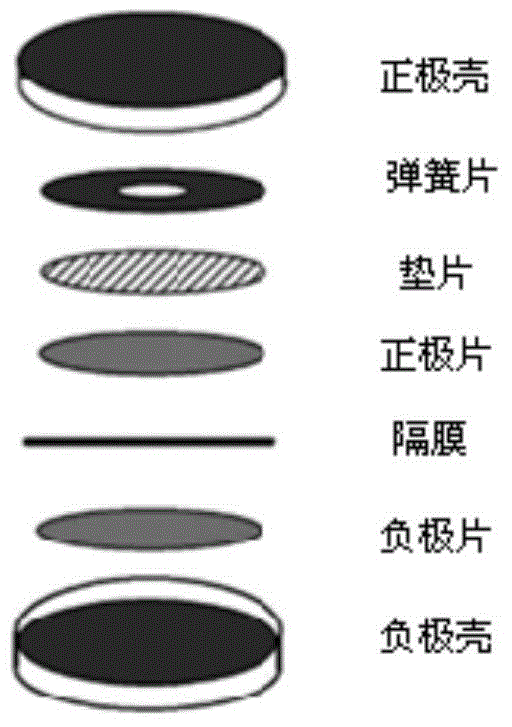

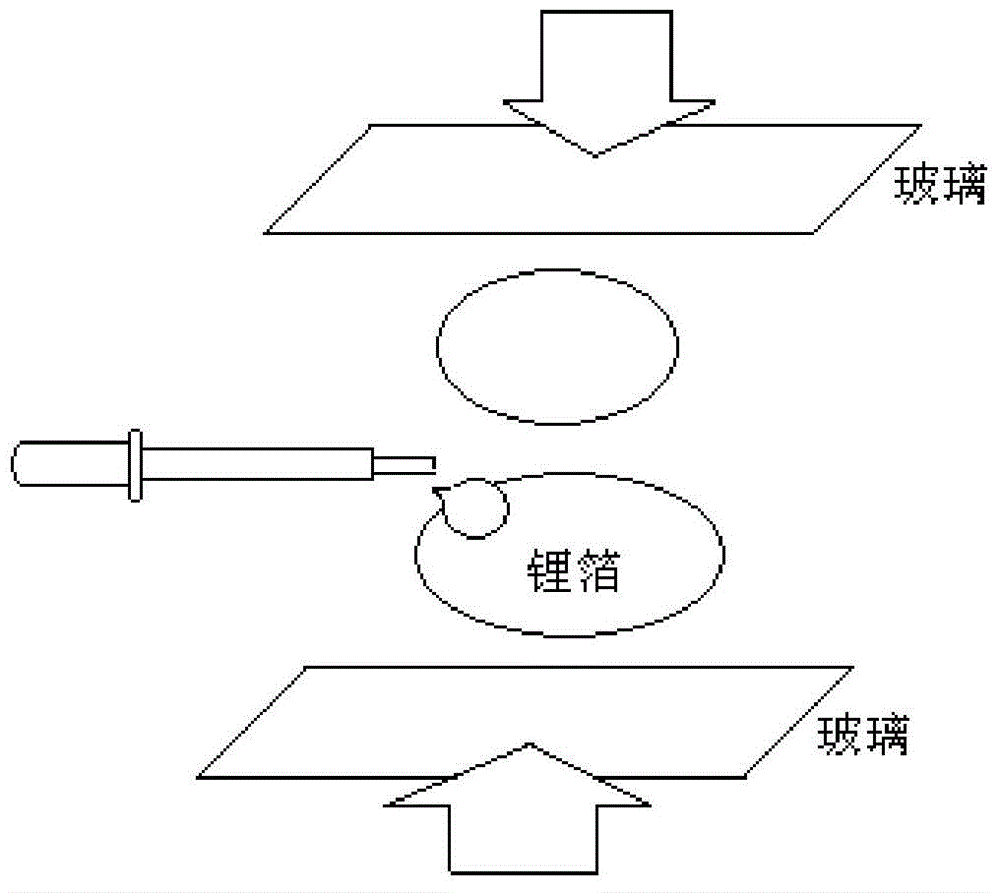

[0027] The present invention selects commercial electrode materials. At present, the electrode material of capacitors is mainly activated carbon, and the commercial negative electrode materials mainly include lithium titanate, artificial graphite, natural graphite, graphitized mesophase carbon microspheres, hard carbon, etc. Considering the working voltage of capacitors, carbon materials are more advantageous due to their lower lithium intercalation potential. Among the above-mentioned carbon materials, hard carbon has high capacity, rate characteristics and cycle characteristics, and is suitable for power lithium ion capacitors. Hard carbon is selected as the negative electrode material, while the positive electrode uses commercialized activated carbon, which is YP-D from Japan, and the negative electrode uses Japanese commercialized hard carbon.

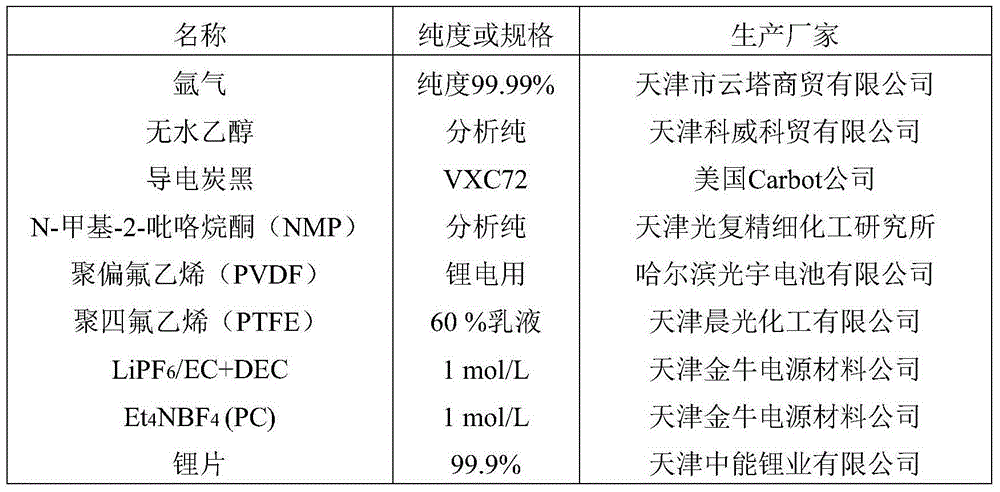

[0028] The specifications and manufac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com