Enzyme biological fuel cell and preparing method thereof

A biofuel cell and electrode technology, applied in the direction of biochemical fuel cells, etc., can solve problems such as instability and unfavorable operation of biofuel cells for a long time, and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1. Construction of Yin and Yang poles in enzyme biofuel cell

[0022] The base electrode used in the enzyme biofuel cell constructed in the experiment is a gold sheet electrode (1cm × 0.5cm), provided by 55 Institute (Nanjing, China). Before use, the gold sheet substrate was polished with absorbent cotton. Then ultrasonic cleaning was performed with ethanol and ultrapure water respectively, and finally blow-dried under nitrogen flow.

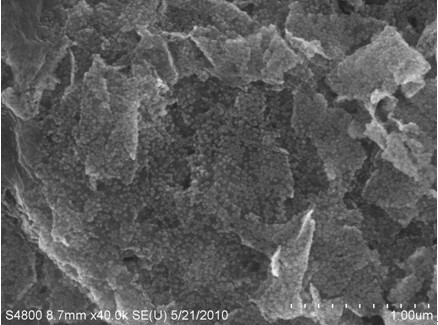

[0023] The preparation of the bioanode was similar to that reported in previous literature [Ref: Y.Chen, Y.Li, D.Sun, D.Tian, J.Zhang, J.-J.Zhu, J.Mater.Chem 2011, 21, 7604-7611.]. The optimal experimental conditions for biocathode preparation are as follows: first, 50 μL (0.75 mg mL -1 ) of the graphene-nano-gold composite solution was dropped onto the gold sheet electrode, and then the gold sheet electrode was dried at a constant temperature of 37°C. After preparing the graphene-nanogold composite electrode, 50 μL laccase s...

Embodiment 2

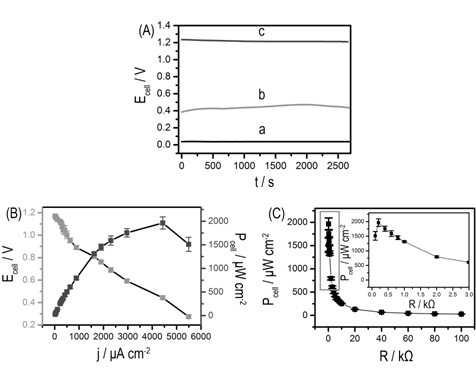

[0024] Example 2. Construction of Enzyme Biofuel Cell

[0025] Perfluorosulfonic acid / PTFE copolymer diaphragm (DuPont TM PFSA NRE-211, with a thickness of 25.4 μm) as a separator between the cathode and anode of a biofuel cell. The anolyte was nitrogen saturated acetate buffer (0.2 M, pH 5.0) containing 50 mM glucose. The catholyte was acetate buffer (0.2M, pH 5.0) containing 0.5mM ABTS, which required saturation with oxygen. When testing the power output curve, when the enzyme biofuel cell obtains a stable open circuit potential, various load values (100Ω~100kΩ) are connected to the two poles of the battery, and a digital multimeter is used to measure the power output on the load. The open circuit potential, polarization curve, power density curve and the relationship between power density curve and external resistance of enzyme biofuel cells are shown in image 3 , the red and yellow light-emitting diodes of the two enzyme biofuel cells were successfully lit, and the...

Embodiment 3

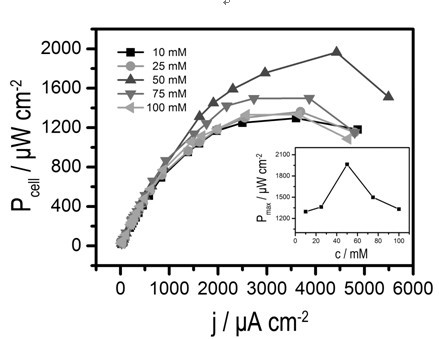

[0026] Example 3. Construction of Enzyme Biofuel Cell

[0027] Build enzyme biofuel cell by the step of embodiment 2, but the concentration of glucose is 10mM, the open circuit potential that obtains, polarization curve and power density curve will be lower than the result of embodiment 2, see figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com