Device and method for synthesizing catalyst by using novel redox coprecipitation method

A co-precipitation method and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of destroying the kinetic balance of precipitation and uneven distribution of catalyst components , Reduce catalyst activity and other issues, achieve the effects of reducing catalyst agglomeration, uniform catalyst synthesis, and stable pH of the reaction solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

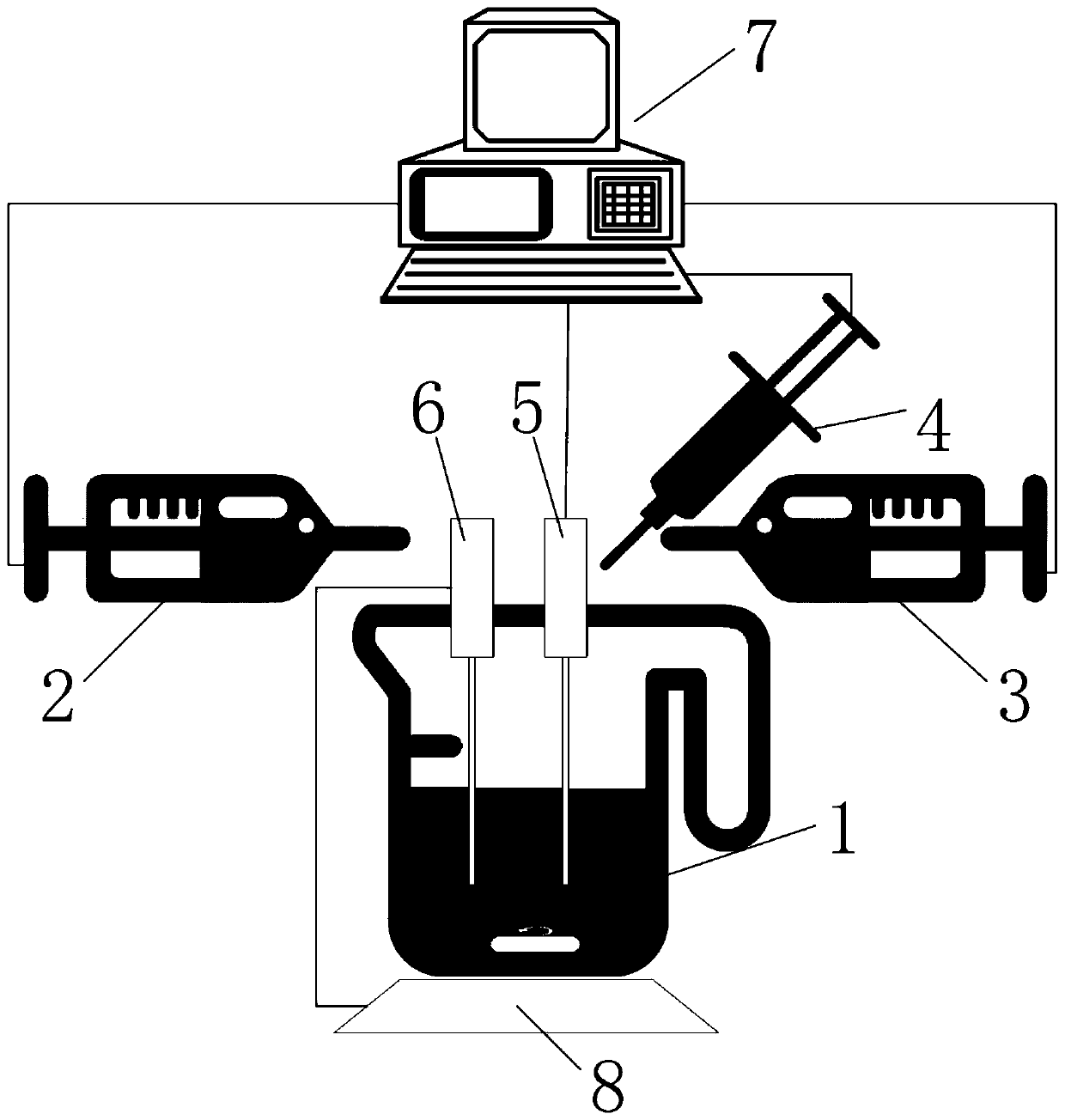

Method used

Image

Examples

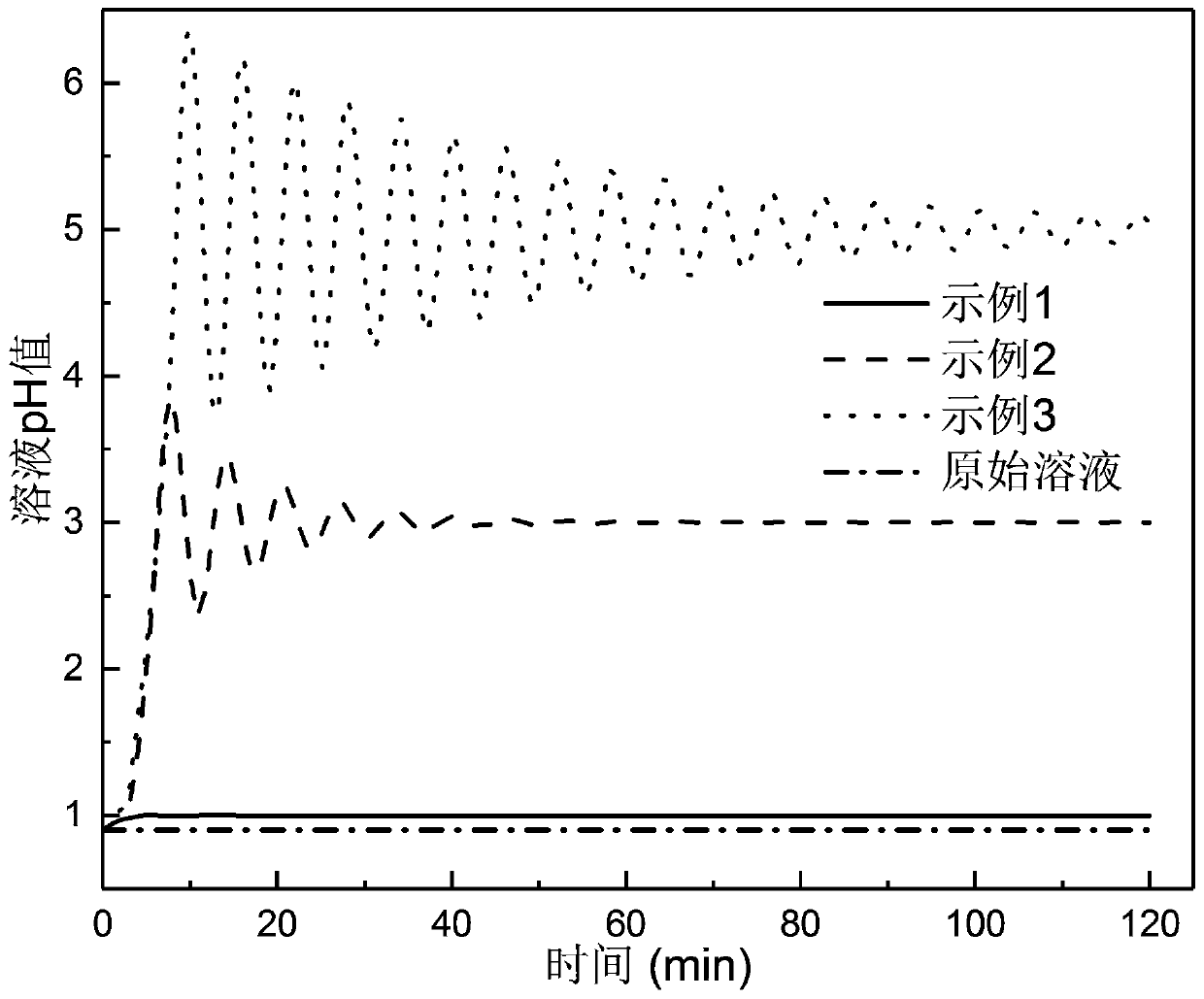

Embodiment 1

[0052] Configure acidic (nitric acid) deionized aqueous solution A (pH=1.0), weigh 9.31g Mn(NO 3 ) 2 50wt%H 2 O is dissolved in solution A to obtain solution B, which is sucked into the reducing solution injection pump 3;

[0053] Configure acidic (nitric acid) deionized aqueous solution C (pH=1.0), weigh 2.78g KMnO 4 Solid and 2.69g (NH 4 ) 2 Ce(NO 3 ) 6 , adding it to solution C, stirring to dissolve it to obtain solution D, and sucking solution D into the oxidizing solution syringe pump 2;

[0054] Configure 0.4M KOH solution E (pH=13.6), and suck the solution E into the alkaline solution syringe pump 4;

[0055] Start the magnetic stirrer 8 with heating function, heat the deionized water in the reaction tank to 70°C, and start the magnetic stirrer;

[0056] Set the pH value (1.0) required for this catalyst synthesis on the host computer 7, the syringe pump starts to work, and injects the reaction chemical solution into the reaction tank;

[0057] After the end, c...

Embodiment 2

[0059] Configure acidic (nitric acid) deionized aqueous solution A (pH=1.0), weigh 9.31g Mn(NO 3 ) 2 50wt%H 2 O is dissolved in solution A to obtain solution B, which is sucked into the reducing solution injection pump 3;

[0060] Configure acidic (nitric acid) deionized aqueous solution C (pH=1.0), weigh 2.78g KMnO 4 Solid and 2.69g (NH 4 ) 2 Ce(NO 3 ) 6 , adding it to solution C, stirring to dissolve it to obtain solution D, and sucking solution D into the oxidizing solution syringe pump 2;

[0061] Configure 0.4M KOH solution E (pH=13.6), and suck the solution E into the alkaline solution syringe pump 4;

[0062] Start the magnetic stirrer 8 with heating function, heat the deionized water in the reaction tank to 70°C, and start the magnetic stirrer;

[0063] The pH value (3.0) required for this catalyst synthesis is set on the upper computer 7, the syringe pump starts to work, and the reaction chemical solution is injected into the reaction tank;

[0064] After th...

Embodiment 3

[0066] Configure acidic (nitric acid) deionized aqueous solution A (pH=1.0), weigh 9.31g Mn(NO 3 ) 2 50wt%H 2 O is dissolved in solution A to obtain solution B, which is sucked into the reducing solution injection pump 3;

[0067] Configure acidic (nitric acid) deionized aqueous solution C (pH=1.0), weigh 2.78g KMnO 4 Solid and 2.69g (NH 4 ) 2 Ce(NO 3 ) 6 , adding it to solution C, stirring to dissolve it to obtain solution D, and sucking solution D into the oxidizing solution syringe pump 2;

[0068] Configure 0.4M KOH solution E (pH=13.6), and suck the solution E into the alkaline solution syringe pump 4;

[0069] Start the magnetic stirrer 8 with heating function, heat the deionized water in the reaction tank to 70°C, and start the magnetic stirrer;

[0070] Set the pH value (5.0) required for this catalyst synthesis on the host computer 7, the syringe pump starts to work, and injects the reaction chemical solution into the reaction tank;

[0071] After the end, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com