Preparation method of SSZ-13 molecular sieve composite material

A 1. SSZ-13, composite material technology, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problems of no mass production, high price, limited prospects, etc., and achieve an improved ratio. Effects of surface area and pore volume, lower production costs, and improved solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

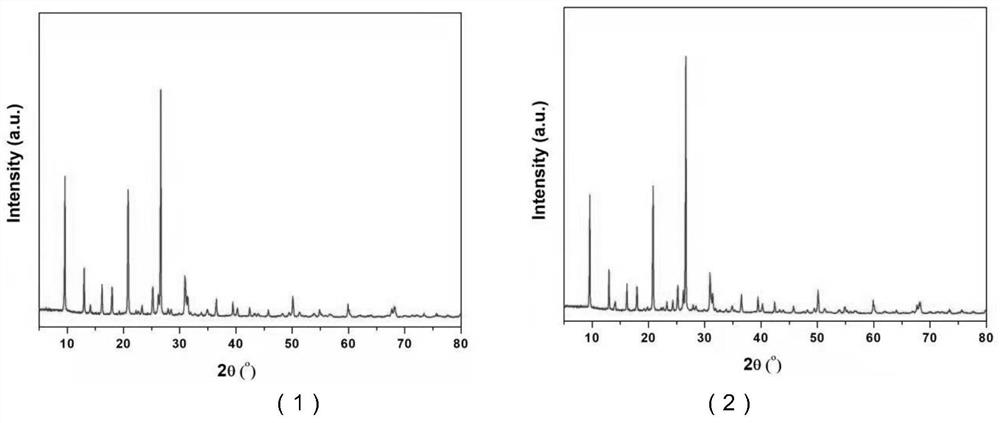

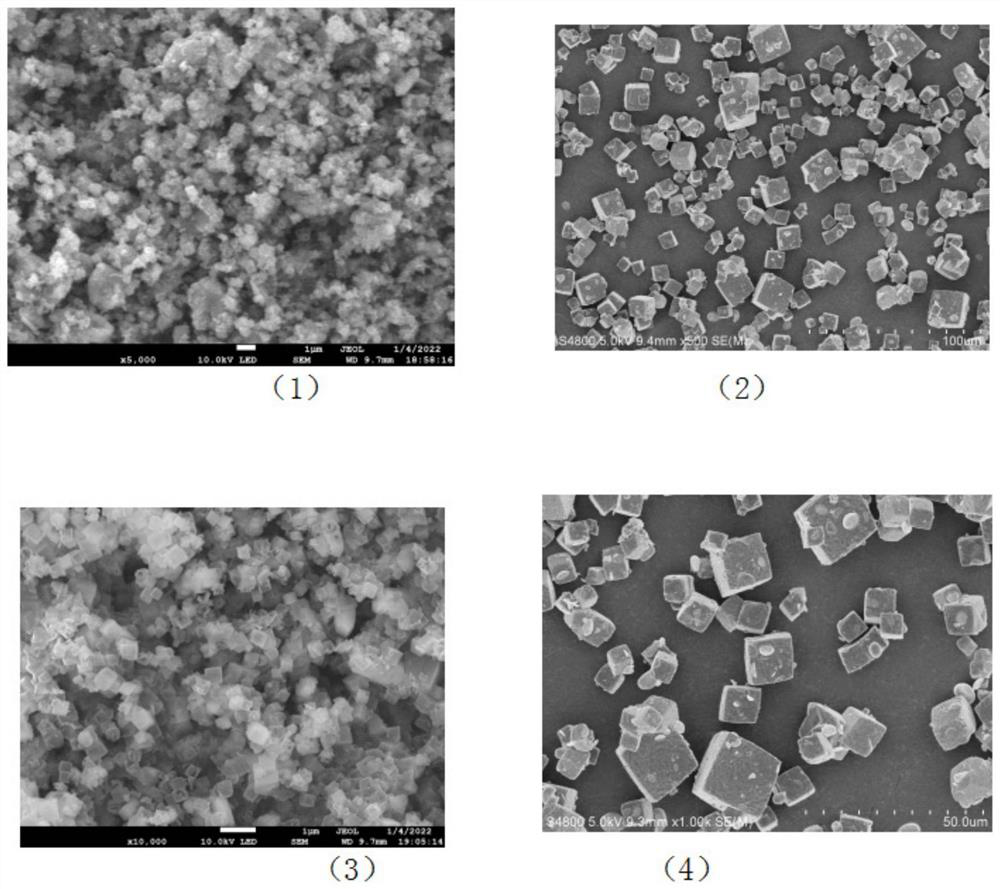

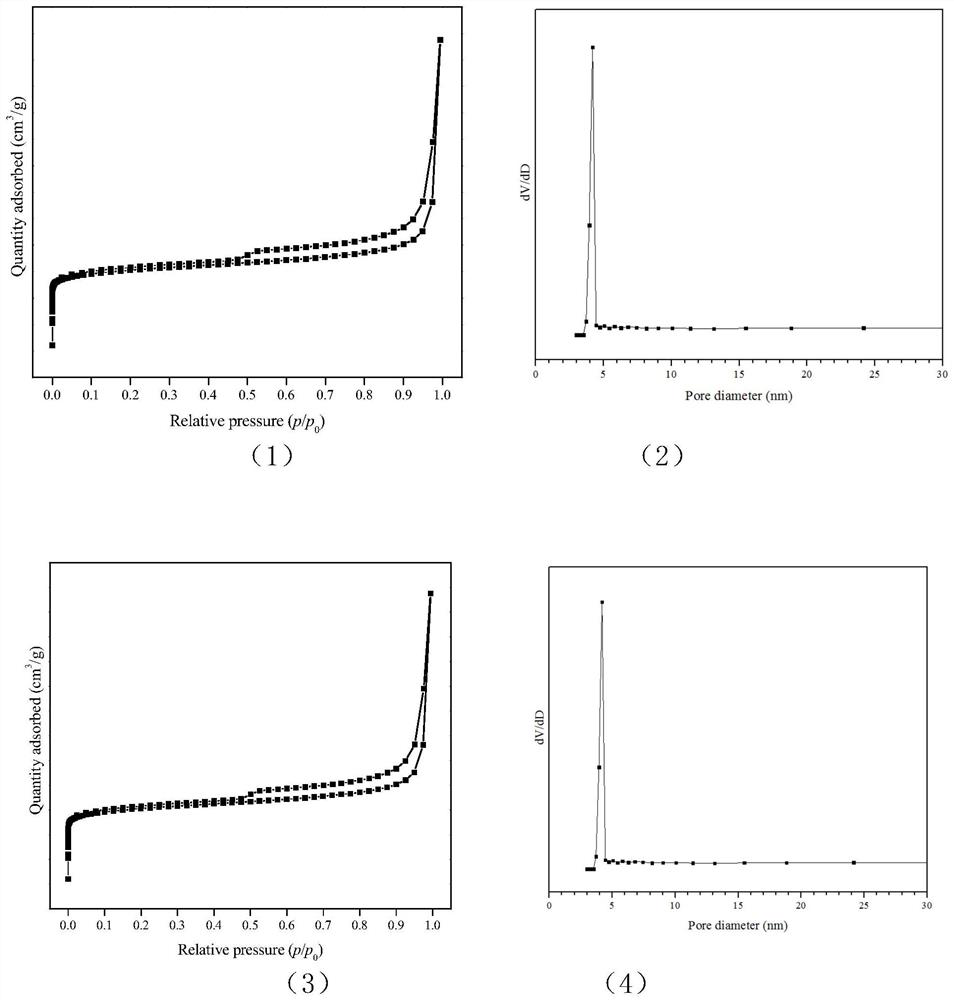

[0048] (1) Synthesis of SSZ-13 molecular sieve seeds:

[0049] (1-1) Weigh the material according to the aluminum source, silicon source, sodium hydroxide, organic amine template agent (R) and water according to the molar ratio of 0.025:1:0.15:0.35:30, and first mix the aluminum source and hydrogen peroxide with water. Sodium was dissolved, stirred for 10 minutes, then added organic amine template (R) and stirred for 1 hour, finally added silicon source and stirred for 6 hours, put it into a reactor with a filling degree of 60%, and crystallized at 150 ° C for 72 hours.

[0050] (1-2) After the reaction, the product is separated by centrifugation or suction filtration, the supernatant liquid is poured off, the remaining solids are continuously added with deionized water, centrifuged after ultrasonication for 10 minutes, and the supernatant liquid is poured out.

[0051] (1-3) Repeat step (2) 3 times until the pH of the supernatant is between 7-8, to obtain solid SSZ-13 molecul...

Embodiment 2

[0062] (1) Synthesis of SSZ-13 molecular sieve seeds:

[0063] (1-1) Weigh the material according to the aluminum source, silicon source, sodium hydroxide, organic amine template agent (R) and water according to the molar ratio of 0.025:1:0.15:0.35:30, and first mix the aluminum source and hydrogen peroxide with water. Sodium was dissolved, stirred for 10 minutes, then added organic amine template (R) and stirred for 1 hour, finally added silicon source and stirred for 6 hours, put it into a reactor with a filling degree of 60%, and crystallized at 170 ° C for 120 hours.

[0064] (1-2) After the reaction, the product was separated by suction filtration, the supernatant liquid was poured off, the remaining solids were continuously added with deionized water, centrifuged after ultrasonication for 10 min, and the supernatant liquid was poured out.

[0065] (1-3) Repeat step (2) 4 times until the pH of the supernatant is between 8, to obtain solid SSZ-13 molecular sieve, dry at 90...

Embodiment 3

[0076] (1) Synthesis of SSZ-13 molecular sieve seeds:

[0077] (1-1) Weigh the materials according to the aluminum source, silicon source, sodium hydroxide, organic amine template agent (R) and water according to the molar ratio of 0.033:1:0.2:0.3:30. Sodium was dissolved, stirred for 10 minutes, then added organic amine template (R) and stirred for 1 hour, finally added silicon source and stirred for 6 hours, put it into a reactor with a filling degree of 60%, and crystallized at 150 ° C for 72 hours.

[0078] (1-2) After the reaction, the product is separated by centrifugation or suction filtration, the supernatant liquid is poured off, the remaining solids are continuously added with deionized water, centrifuged after ultrasonication for 10 minutes, and the supernatant liquid is poured out.

[0079] (1-3) Step (2) was repeated 4 times until the pH of the supernatant liquid was between 8 to obtain solid SSZ-13 molecular sieve, which was dried at 100° C. and ground to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com