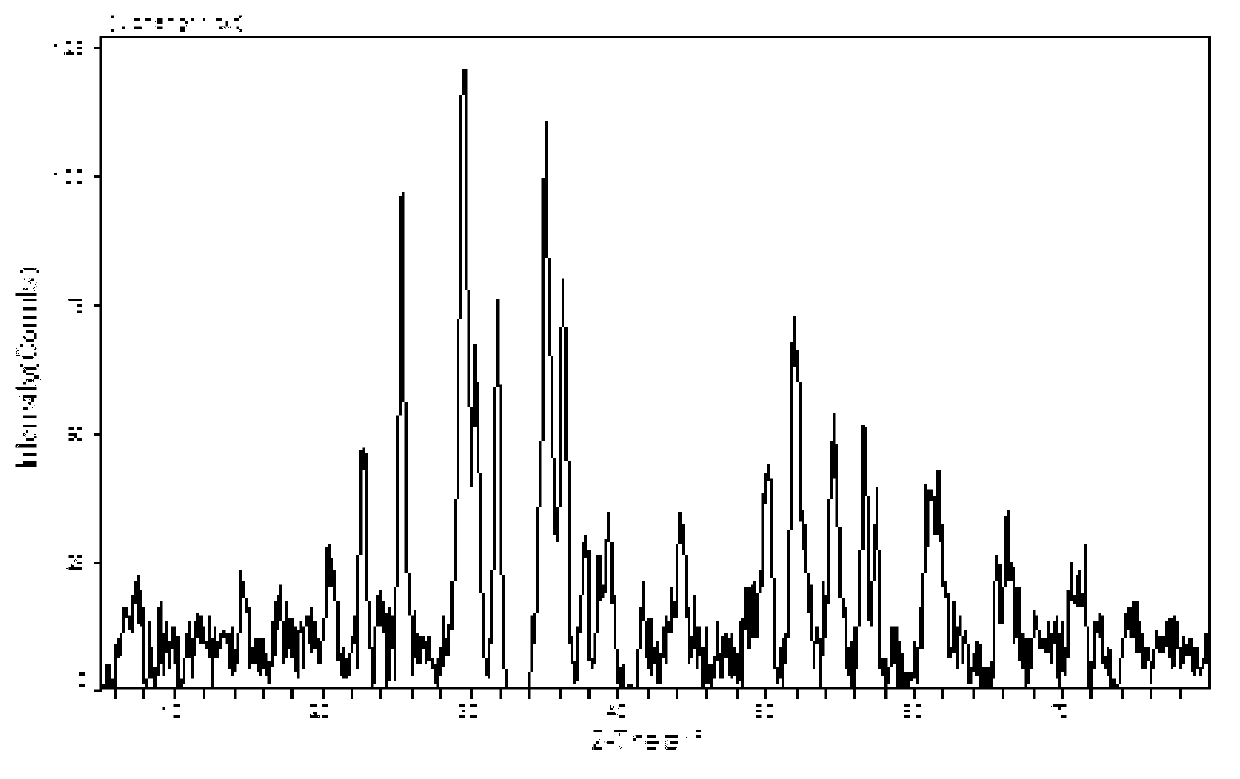

High-performance lithium iron phosphate cathode material and preparation method of lithium iron phosphate cathode material

A technology for lithium iron phosphate and cathode materials, applied in chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve problems such as poor repeatability, complicated operation, and impact on material tap density, and achieve cost reduction and uniform particle distribution , the effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

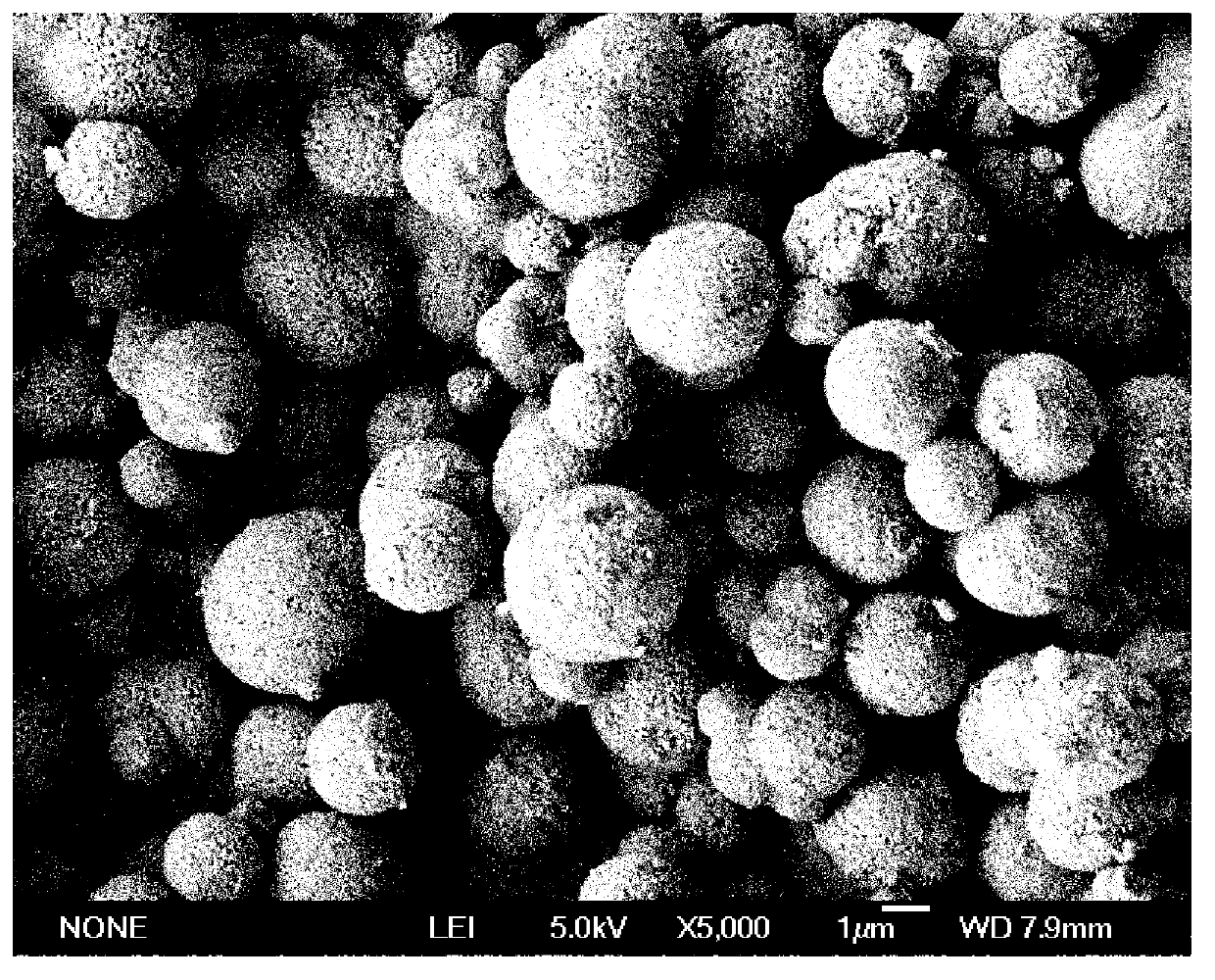

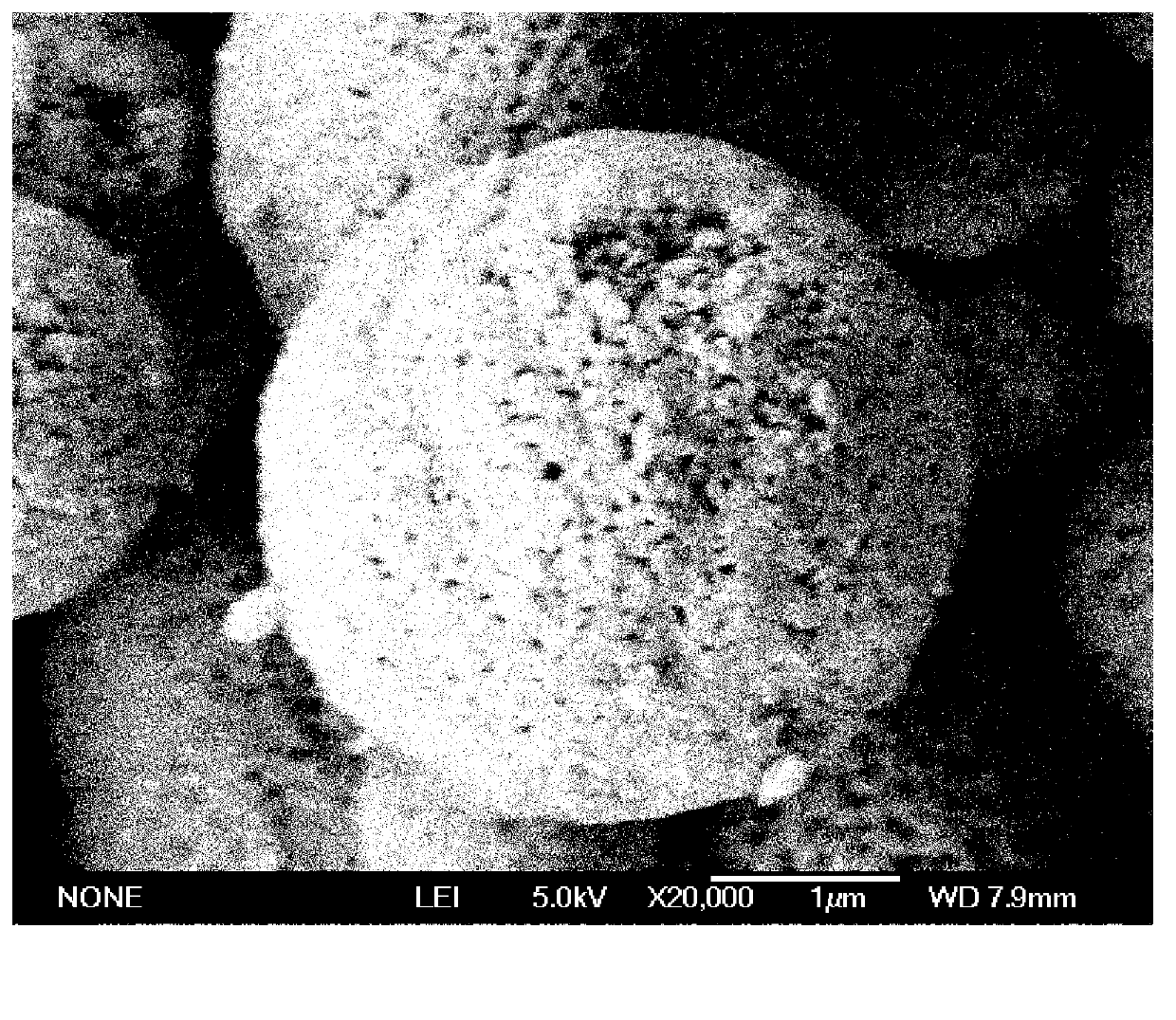

Embodiment 1

[0059] (1) Add 7.5g TiO 2 Mixed with 400mL of 5M NaOH solution, ultrasonically mixed for 3h, transferred to a 500mL hydrothermal kettle, and placed in an oven at 200°C for 40h of hydrothermal reaction. After the reaction, take out the reaction kettle, after natural cooling, filter to obtain the product, fully wash with 0.3M dilute sulfuric acid and keep stirring until the pH reaches neutral, then wash with deionized water and absolute ethanol several times after suction filtration, After drying at 100°C, titanic acid nanowires were obtained. Put titanate nanowires in a crucible, keep it warm at 600°C for 3 hours, and cool it down to room temperature naturally to get TiO 2 Nanowires.

[0060] (2) Weigh 3.6g V 2 o 5 Put it in a beaker, add 30mL of n-hexanol and 70mL of deionized water, stir magnetically for 1h, transfer the orange suspension to the reaction kettle, and keep it at 200°C for 60 hours. After the reaction, take out the reaction kettle, cool naturally, and filter...

Embodiment 2

[0065] TiO 2 nanowire with V 3 o 7 The synthesis of nanowires is the same as in Example 1.

[0066] Weigh 7.3g of lithium hydroxide and 34.1g of iron phosphate, dissolve LiOH in deionized water, add iron phosphate to the above solution after it is completely dissolved, and obtain a homogeneous solution by ultrasonication, add 20g of citric acid into the above solution, and then add 0.133g V 3 o 7 , add deionized water to make the volume to 350mL, transfer to a 500mL reactor, and keep the temperature at 150°C for 10 hours. After the reactor was cooled to room temperature, the product was washed several times with deionized water, centrifuged and analyzed, and the precipitate was dried at 100° C. for 10 h to obtain a green lithium iron phosphate precursor. Weigh the green precursor, mix it with citric acid with a mass ratio of carbon: precursor = 0.07:1, ball mill it at a speed of 300rmp for 1 hour, transfer it to a crucible, and heat it at 5°C under the protection of a nit...

Embodiment 3

[0069] TiO 2 nanowire with V 3 o 7 The synthesis of nanowires is the same as in Example 1.

[0070] Weigh 7.3g of lithium hydroxide and 34.1g of iron phosphate, dissolve LiOH in deionized water, add iron phosphate to the above solution after it is completely dissolved, and obtain a homogeneous solution by ultrasonication, weigh 16.1g of ascorbic acid and 33.7g of ammonium bicarbonate and add In the above solution, then add 0.157g TiO 2 with 0.133g V 3 o 7 , add deionized water to make the volume to 350mL, transfer to a 500mL reactor, and keep the temperature at 180°C for 10 hours. After the reactor was cooled to room temperature, the product was washed several times with deionized water, centrifuged and analyzed, and the precipitate was dried at 100° C. for 10 h to obtain a green lithium iron phosphate precursor. Weigh the green precursor, mix it with glucose with a mass ratio of carbon: precursor = 0.05:1, ball mill at 300rmp for 1 hour, transfer to a crucible, and unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com