Marine Gas Hydrate Accumulation-Development Simulation Experiment System and Method

A simulation experiment and natural gas technology, applied in teaching models, mining fluids, earth square drilling, etc., can solve the problems of low natural gas hydrate velocity, reduced natural gas seepage capacity, low conversion rate of water-generated hydrate, etc., and achieve uniform synthesis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to have a clearer understanding of the technical features and purposes of the present invention, the technical solutions of the present invention are now described in detail below, but should not be construed as limiting the scope of implementation of the present invention. Under the teaching of the present invention, the skilled person can conceive any possible modifications based on the present invention, and these should be regarded as belonging to the scope of the present invention.

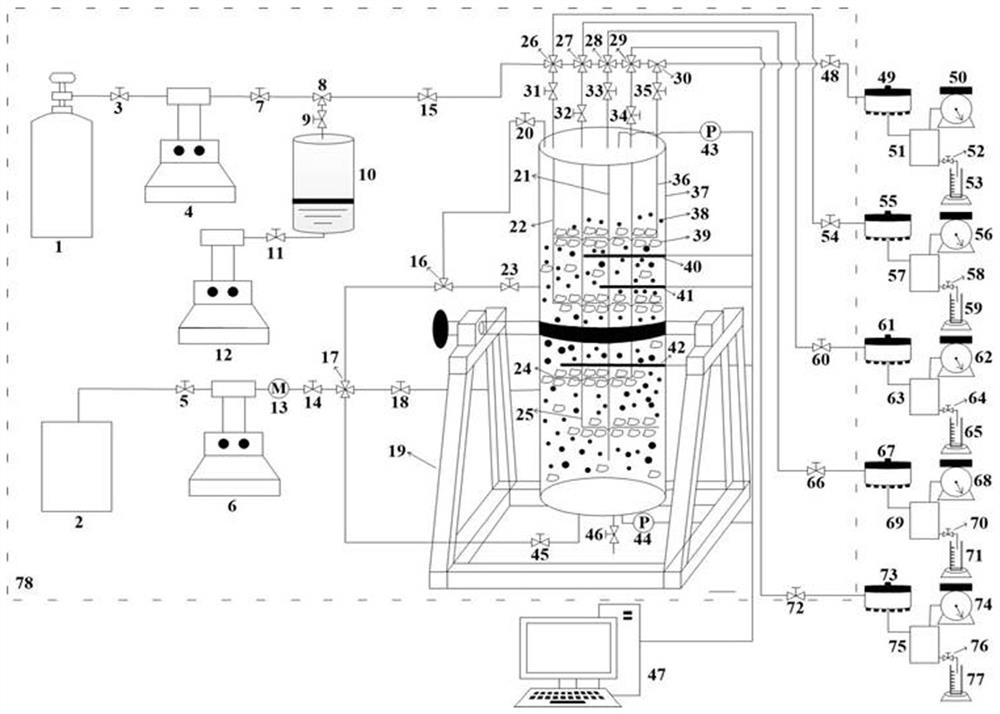

[0049] The marine gas hydrate accumulation-development simulation experiment system consists of a fluid injection part, a hydrate synthesis / decomposition part and a produced fluid metering part.

[0050] The fluid injection part includes a high-pressure displacement pump, a natural gas bottle, an intermediate container and a seawater storage tank. The natural gas bottle and the intermediate container are respectively connected to the top of the high-pressure reactor through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com