Nitrogen-sulfur-phosphorus doped ordered mesoporous carbon material, preparation method and application thereof

A technology of mesoporous carbon and carbon materials, which is applied in the field of nitrogen, sulfur, and phosphorus doped ordered mesoporous carbon materials and their preparation, can solve the problem of producing ordered mesoporous carbon materials, large size, and insufficient structure of ordered mesoporous carbon materials. Uniformity and other issues, to achieve the effects of good uniformity, improved capacitance performance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

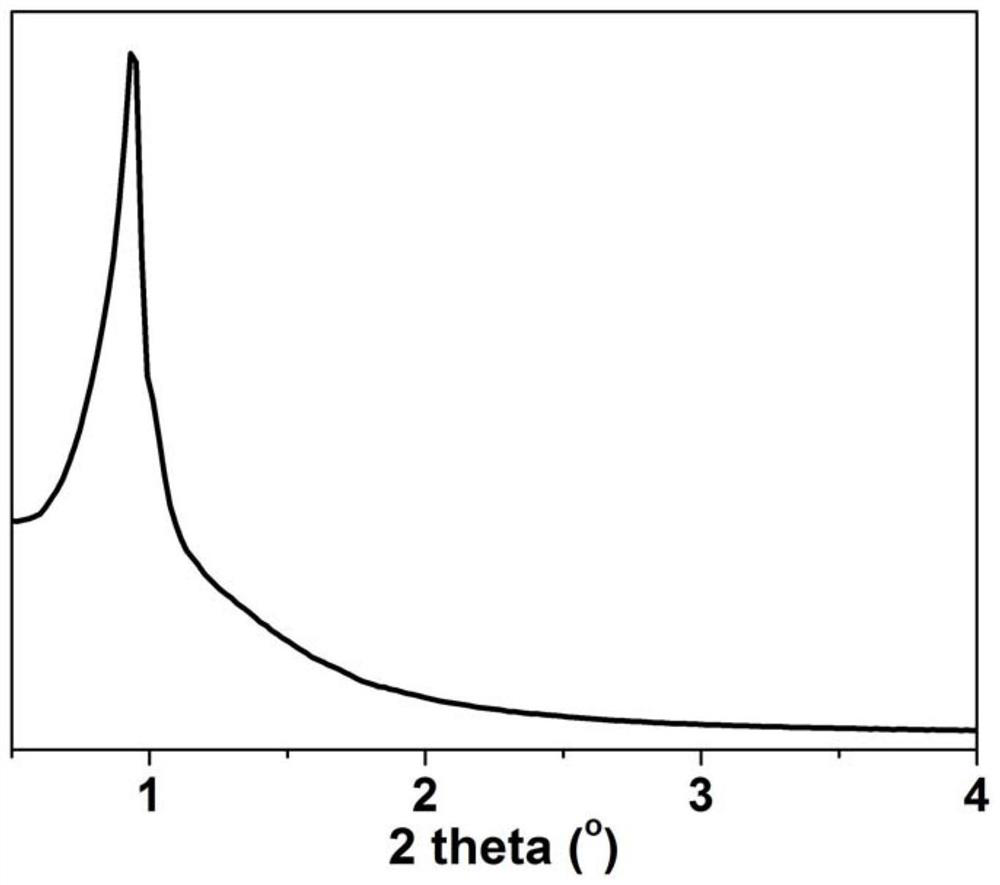

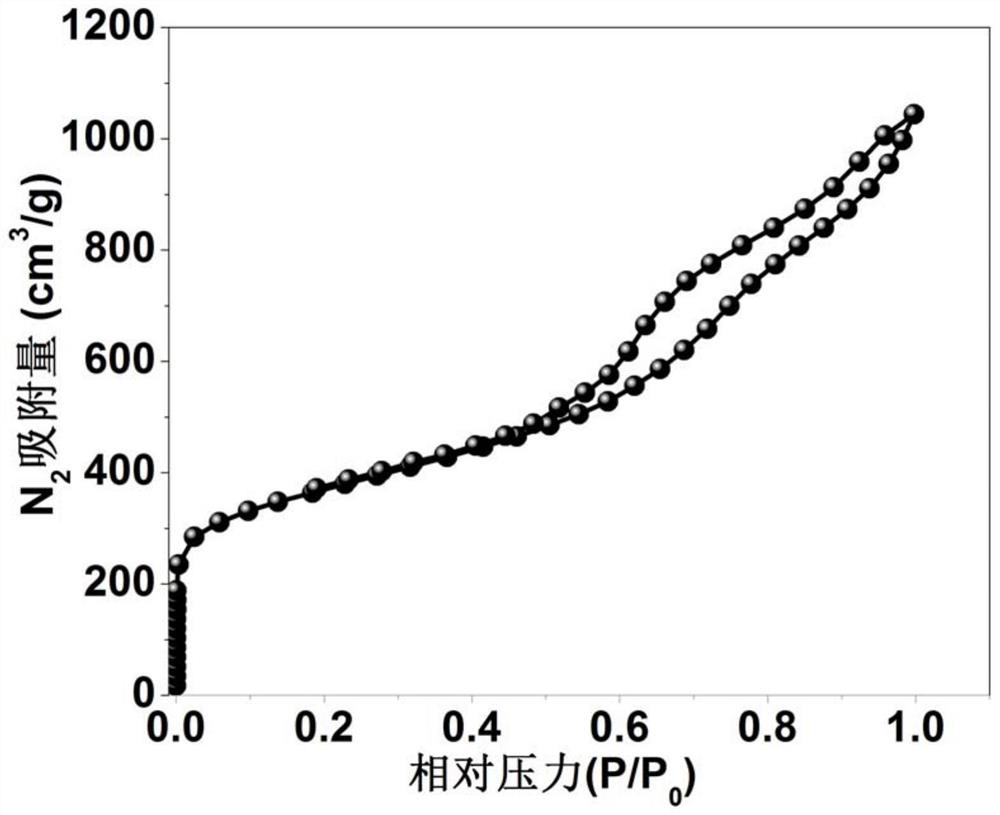

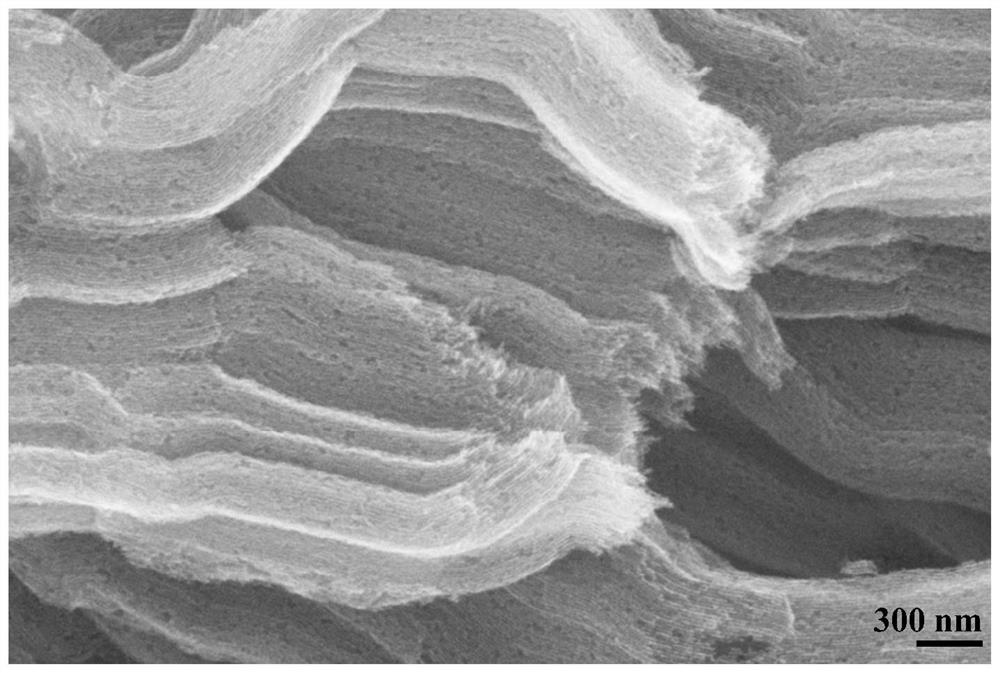

[0033] (1) Preparation of nitrogen, sulfur, phosphorus ordered mesoporous carbon materials

[0034] Add 0.10g of phosphoric acid and 0.10g of sulfuric acid into 5mL of methanol, stir evenly, add 1.0g of ordered mesoporous silica molecular sieve SBA-15, ultrasonicate for 5min, then heat in a water bath at 90°C to evaporate the solvent, and fry to dryness Finally, SBA-15 loaded with sulfuric acid and phosphoric acid in the pores was obtained. Put 1.0g of SBA-15 loaded with sulfuric acid and phosphoric acid at the bottom of the inner tank of the hydrothermal kettle, and then place the small glass bottle containing 0.20g of pyrrole and 0.30g of 2-aminopyrrole in the hydrothermal kettle, at 180°C After heating for 2 hours to volatilize pyrrole and 2-aminopyrrole, gas phase pyrrole and gas phase 2-aminopyrrole also enter the pores of SBA-15, and polymerize with sulfuric acid and phosphoric acid in the pores to obtain polypyrrole compounds and SBA-15 compound. The composite was car...

Embodiment 2

[0038] (1) Preparation of nitrogen, sulfur, phosphorus ordered mesoporous carbon materials

[0039]Add 0.20g of phosphoric acid and 0.10g of sulfuric acid into 5mL of methanol, stir evenly, add 1.0g of ordered mesoporous silica molecular sieve SBA-15, ultrasonicate for 5min, then heat in a water bath at 90°C to evaporate the solvent, and fry to dryness Finally, SBA-15 loaded with sulfuric acid and phosphoric acid in the pores was obtained. Put 1.0g of SBA-15 loaded with sulfuric acid and phosphoric acid at the bottom of the inner tank of the hydrothermal kettle, and then place the small glass bottle containing 0.30g of pyrrole and 0.20g of 2-aminopyrrole in the hydrothermal kettle, at 180°C After heating for 2 hours to volatilize pyrrole and 2-aminopyrrole, gas phase pyrrole and gas phase 2-aminopyrrole also enter the pores of SBA-15, and polymerize with sulfuric acid and phosphoric acid in the pores to obtain polypyrrole compounds and SBA-15 compound. The composite was carb...

Embodiment 3

[0043] (1) Preparation of nitrogen, sulfur, phosphorus ordered mesoporous carbon materials

[0044] Add 0.40g of phosphoric acid and 0.40g of sulfuric acid into 5mL of methanol, stir evenly, add 1.0g of ordered mesoporous silica molecular sieve SBA-15, ultrasonicate for 5min, then heat in a water bath at 90°C to volatilize the solvent, and fry to dryness Finally, SBA-15 loaded with sulfuric acid and phosphoric acid in the pores was obtained. Put 1.0g of SBA-15 loaded with sulfuric acid and phosphoric acid at the bottom of the inner tank of the hydrothermal kettle, and then place the small glass bottle containing 0.10g of pyrrole and 0.10g of 2-aminopyrrole in the hydrothermal kettle, at 180°C After heating for 2 hours to volatilize pyrrole and 2-aminopyrrole, gas phase pyrrole and gas phase 2-aminopyrrole also enter the pores of SBA-15, and polymerize with sulfuric acid and phosphoric acid in the pores to obtain polypyrrole compounds and SBA-15 compound. The composite was ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com