Vacuum crystallization device for titanium dioxide

A technology of vacuum crystallization and titanium dioxide, which is applied in the direction of crystallization separation, solution crystallization, and selection of crystallization auxiliary conditions. It can solve the problems of poor diversion effect of the guide tube, poor helicity of the liquid flow, and influence on the crystallization effect, and achieve large stirring. effect, uniform crystal particle size distribution, crystallization speed and enhanced crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

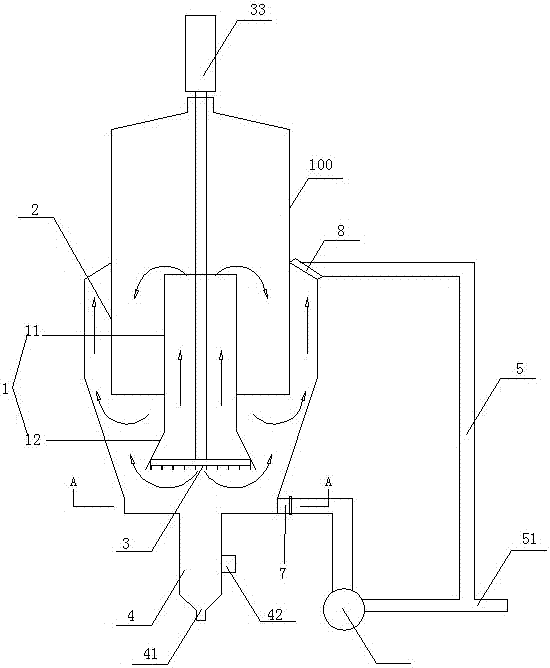

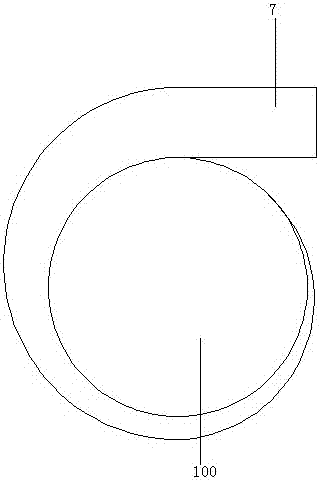

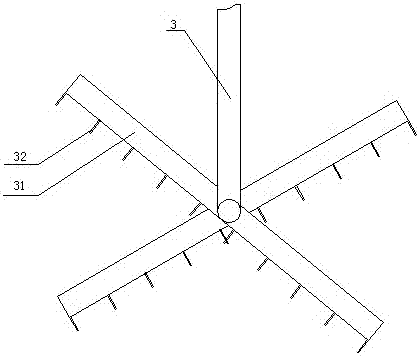

[0028] Such as figure 1 , figure 2 , image 3 As shown, a titanium dioxide vacuum crystallization device includes a crystallization tank 100, and the crystallization tank includes a guide tube 1, a baffle plate 2, a propeller 3, an elutriation tube 4, and a circulation tube 5, and the guide tube is arranged inside the crystallization tank. The flow tube includes an upper cylindrical flow guide tube 11 and a lower conical flow guide tube 12. The inner side of the crystallization tank is provided with a cylindrical baffle, and the lower conical flow guide tube is provided with a stirring paddle, which is connected to a stirring motor. 33. The stirring paddle includes a main paddle 31 and an auxiliary paddle 32. The auxiliary paddle is arranged on the lower side of the main paddle. An elutriation tube is provided at the bottom of the crystallization tank, and a mother liquor outlet 41 and a crystal outlet 42 are arranged at the bottom of the elutriation tank. There is a crysta...

Embodiment 2

[0032] Such as Figure 4 As shown, a titanium dioxide vacuum crystallization device 100, the top of the crystallization tank is connected to a cooling water system 200, and the cooling water system can better promote crystal formation. The circulation pipe is connected with a circulation pump, and a heating device 300 is arranged on the circulation pipe. The heating of the heating device makes it easy for the fine crystals in the reflux liquid to dissolve and form supersaturation, and return to the crystallization tank for recrystallization. And connect the crystal pump 6 at the crystal outlet. The rest of the structure is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com