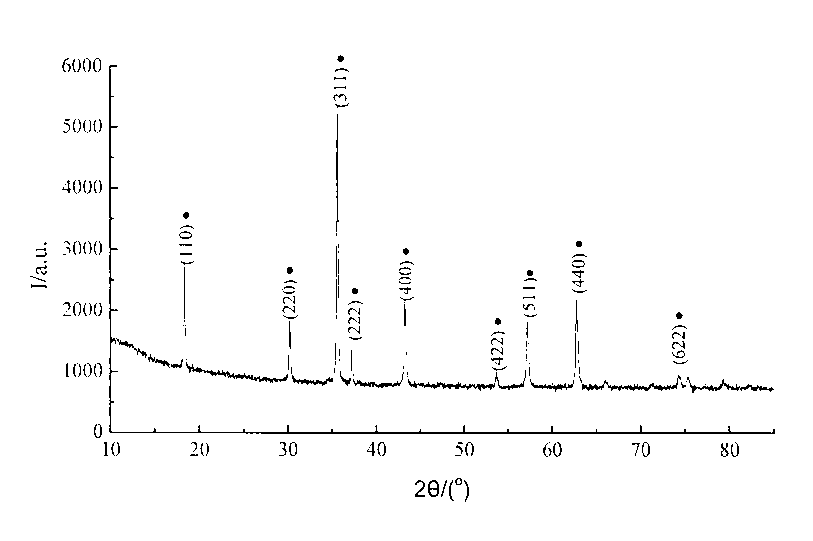

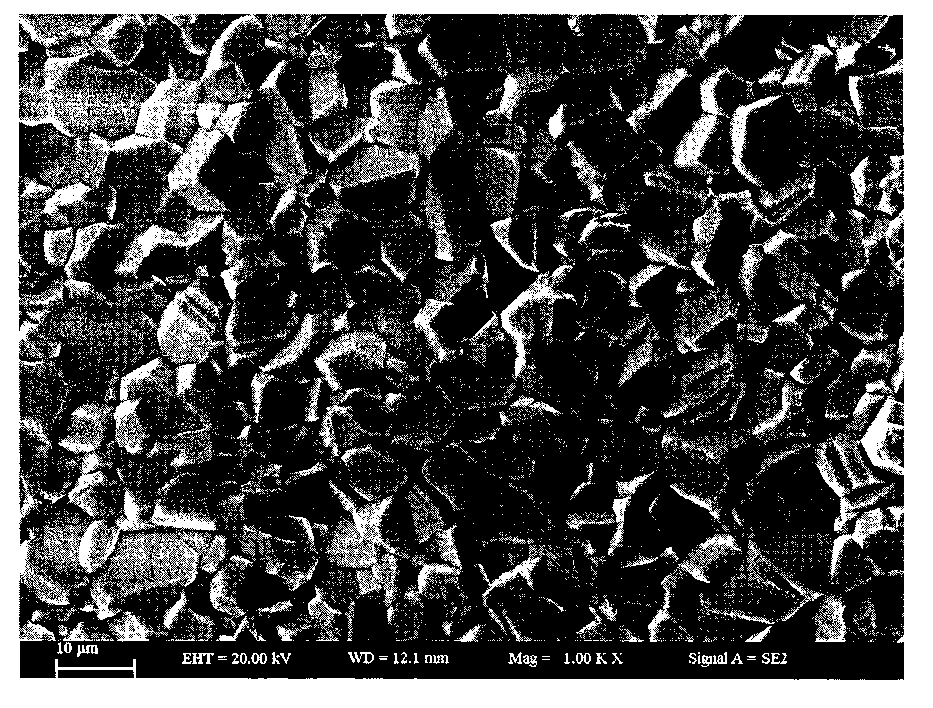

Negative temperature coefficient heat sensitive ceramic material preparation method

A negative temperature coefficient, heat-sensitive ceramic technology, applied in the field of temperature sensor preparation, can solve the problems of unsuitability for industrial production, differences in the proportion of powder elements, difficulty in obtaining stoichiometric ratios, etc. Easy-to-control parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] a. Weigh manganese dioxide, nickel oxide and magnesium oxide in a molar ratio of 1.7:0.8:0.5 and place them in a container, add deionized water, and stir for 10 minutes at a speed of 80r / min in a water bath at a temperature of 30°C , to get a mixture;

[0023] b. Mix manganese dioxide, nickel trioxide and magnesium oxide in equal parts with functional additive oxalic acid in a molar ratio of 1:1, add solvent and stir in deionized water, and configure it into a solution with a concentration of 1mol / L. Add it into the mixture obtained in step a, continue to keep stirring in the water bath, and at the same time perform ultrasonic treatment, the frequency of the ultrasonic wave is 15kHz, and the power is 100W to make the mixing more uniform until the solvent evaporates to obtain a viscous mixture;

[0024] c. drying the mixture obtained in step b in an oven at a temperature of 70° C. for 8 hours to obtain a powder;

[0025] d. Calcining the powder obtained in step c at a t...

Embodiment 2

[0028] a. Weigh manganese dioxide, nickel trioxide and iron oxide in a molar ratio of 1.6:0.5:1 and place them in a container, add deionized water and stir for 20 minutes at a speed of 100r / min in a water bath at a temperature of 50°C , to get a mixture;

[0029] b. Mix manganese dioxide, nickel sesquioxide and iron oxide with citric acid as the functional additive in a molar ratio of 1:1.5, add the solvent and stir evenly in absolute ethanol, and configure it into a solution with a concentration of 5mol / L. Add it to the mixture obtained in step a, continue to keep stirring in the water bath, and perform ultrasonic treatment at the same time, the frequency of the ultrasonic wave is 20kHz, and the power is 500W to make the mixing more uniform until the solvent evaporates to obtain a viscous mixture;

[0030] c. drying the mixture obtained in step b at a temperature of 100° C. under vacuum for 10 hours to obtain a powder;

[0031] d. Calcining the powder obtained in step c at a...

Embodiment 3

[0034] a. Weigh analytically pure manganese dioxide and nickel sesquioxide in a container with a molar ratio of 2.1:0.9, add deionized water, and stir for 40 minutes at a speed of 150 r / min in a water bath at a temperature of 70°C. get the mixture;

[0035] b. Mix manganese dioxide and nickel trioxide in equal parts with functional additive oxalic acid at a molar ratio of 1:2, and add a solvent that is a mixture of deionized water and absolute ethanol with a mass ratio of 1:1 and stir evenly. Be configured as a solution with a concentration of 8mol / L, add it to the mixture obtained in step a, continue to keep stirring in a water bath, and perform ultrasonic treatment at the same time. thick mixture;

[0036] c. drying the mixture obtained in step b in an oven at a temperature of 90° C. for 18 hours to obtain a powder;

[0037] d. Calcining the powder obtained in step c at a temperature of 850° C. for 6 hours to obtain a uniformly mixed powder;

[0038] e. The powder obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com