Solid electrolyte modified lithium titanate negative electrode material and preparation method thereof

A solid electrolyte, negative electrode material technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of poor material cycle and rate performance, poor appearance and quality of pole pieces, unstable coating process, etc. Controllable secondary particle size, low cost, and improved cycle and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0028] This embodiment provides a solid electrolyte modified lithium titanate negative electrode material. The microscopic appearance of the lithium titanate negative electrode material is as follows: the secondary particles are spherical and have a particle size of 5-20 μm. It is composed of primary particles of 20-200 nm; lithium titanate particles in the lithium titanate negative electrode material are attached with a lithium ion solid electrolyte composed of fluoride oxide and fluoride, and the mass fraction of the lithium ion solid electrolyte is 1%.

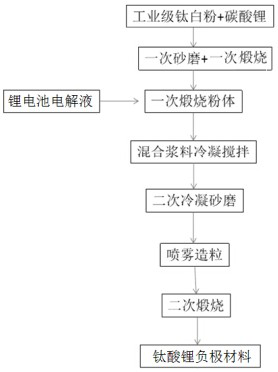

[0029] The preparation method of the above-mentioned solid electrolyte modified lithium titanate negative electrode material is as follows (the process flow is as follows: figure 1 ):

[0030] Mix industrial-grade anatase-type titanium dioxide with lithium carbonate and deionized water, grind and mix thoroughly in a sand mill, and prepare a suspension A with a solid content of 10%. Suspension A was prepared into precursor ...

Embodiment approach 2

[0032]This embodiment provides a solid electrolyte modified lithium titanate negative electrode material. The microscopic appearance of the lithium titanate negative electrode material is as follows: the secondary particles are spherical and have a particle size of 5-20 μm. It is composed of primary particles of 20-200 nm; lithium titanate particles in the lithium titanate negative electrode material are attached with a lithium ion solid electrolyte composed of fluoride oxide and fluoride, and the mass fraction of the lithium ion solid electrolyte is 2%.

[0033] The preparation method of the above-mentioned solid electrolyte modified lithium titanate negative electrode material is as follows (the process flow is as follows: figure 1 ):

[0034] Mix industrial-grade anatase-type titanium dioxide with lithium hydroxide and deionized water, and grind and mix thoroughly in a sand mill to prepare a suspension A with a solid content of 12%. Suspension A was prepared into precursor...

Embodiment approach 3

[0036] This embodiment provides a solid electrolyte modified lithium titanate negative electrode material. The microscopic appearance of the lithium titanate negative electrode material is as follows: the secondary particles are spherical and have a particle size of 5-20 μm. It is composed of primary particles of 20-200 nm; the lithium titanate particles in the lithium titanate negative electrode material are attached with a lithium ion solid electrolyte composed of fluoride oxide and fluoride, and the mass fraction of the lithium ion solid electrolyte is 1.5%.

[0037] The preparation method of the above-mentioned solid electrolyte modified lithium titanate negative electrode material is as follows (the process flow is as follows: figure 1 ):

[0038] Mix industrial-grade anatase-type titanium dioxide with lithium oxalate and deionized water, grind it in a sand mill and mix thoroughly to prepare a suspension A with a solid content of 8%. Suspension A was prepared into precur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com