Solid-waste-based nanocrystalline cluster magnetic glass ceramic and preparation method thereof

A magnetic glass and nanocrystalline technology, which is applied in glass manufacturing equipment, glass furnace equipment, glass production, etc., can solve the problem of low reuse value and achieve high crystal phase purity, rich functional applications, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

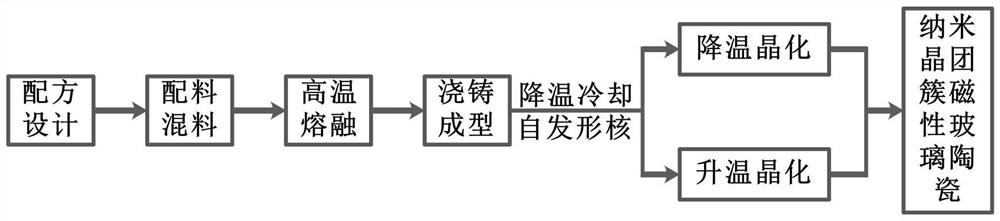

[0036] A solid waste-based nanocrystalline cluster magnetic glass-ceramic is prepared by the method of high-temperature melting-spontaneous nucleation-heating crystallization, and the specific steps are as follows:

[0037] (1) Preparation of mixture: design B 2 o 3 -Fe 2 o 3 -SiO 2 It is a basic glass formula, in which the weight percentage of each component is: SiO 2 50%, Fe 2 o 3 25%, B 2 o3 12%, Al 2 o 3 5%, Na 2 O+K 2 O 5%, MgO+CaO 3%.

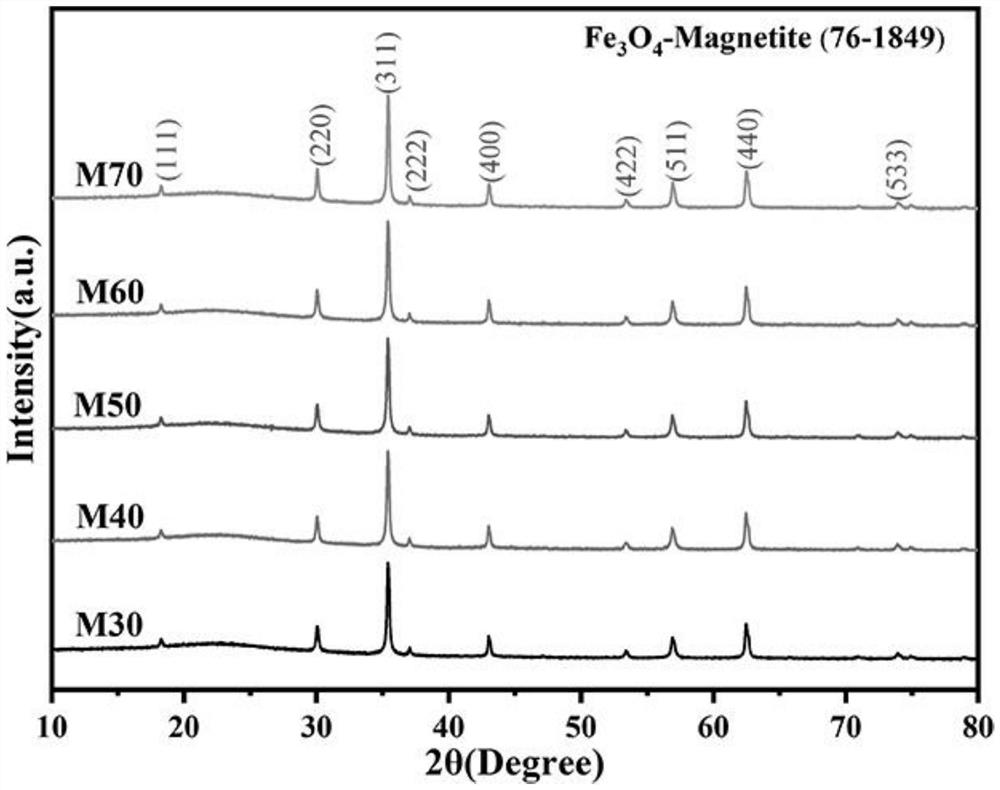

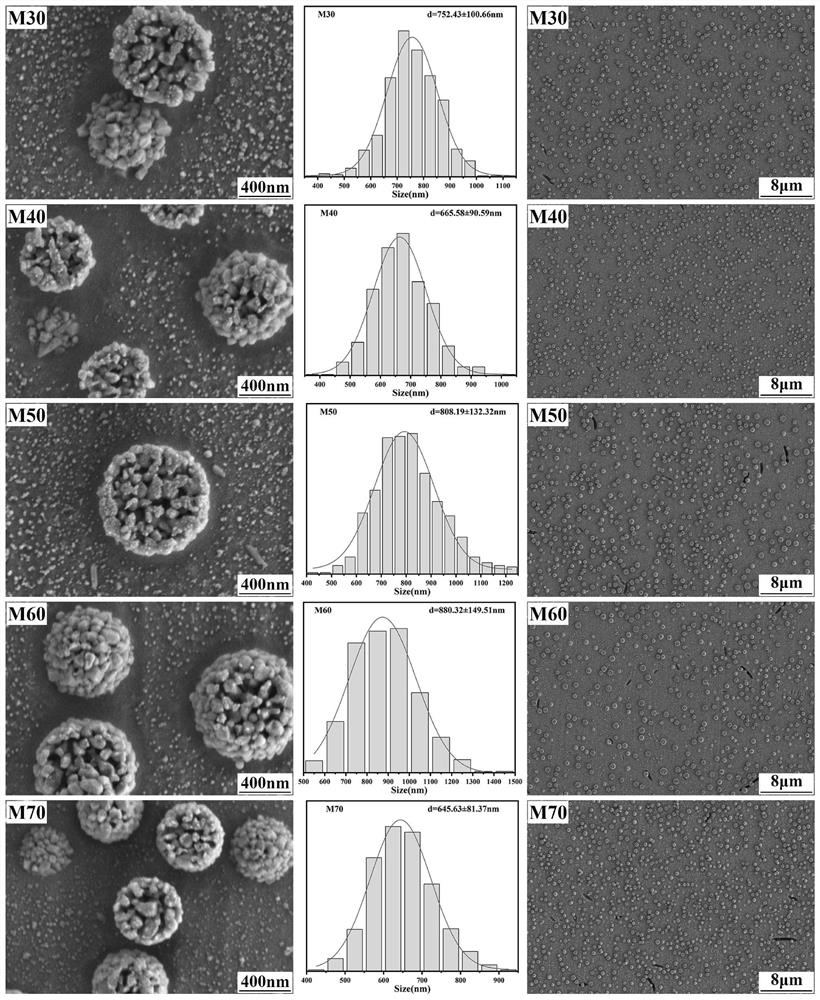

[0038] Using high-silicon molybdenum tailings as the main raw material (see Table 1 for its main components), with appropriate amount of quartz sand, ferric oxide, boron oxide, aluminum oxide, calcium oxide, soda ash, etc., according to the weight of each component in the above basic glass formula Calculate the percentage of glass frit, weigh the raw materials, and mix them evenly. Among them, glass frits with high silicon molybdenum tailings introduction (weight percentage) of 30%, 40%, 50%, 60%, and 70% were designed re...

Embodiment 2

[0051] A solid waste-based nanocrystalline cluster magnetic glass-ceramic is prepared by the method of high-temperature melting-spontaneous nucleation-heating crystallization, and the specific steps are as follows:

[0052] (1) Preparation of the mixture:

[0053] Design B 2 o 3 -Fe 2 o 3 -SiO 2 Glass formula: the weight percentage of each component is composed of: SiO 2 51%, Fe 2 o 3 22%, B 2 o 3 13%, Na 2 O+K 2 O 2%, Al 2 o 3 3%, MgO+CaO 9%.

[0054] Using the iron-rich Baiyun Obo tailings as the main raw material (see Table 3 for its main components), with appropriate amount of auxiliary raw materials such as quartz sand, soda ash, boric acid, etc., according to Design B 2 o 3 -Fe 2 o 3 -SiO 2 The glass formula is used for weighing and mixing evenly.

[0055] Table 3 Main chemical components of Baiyan Obo iron tailings (wt.%)

[0056] SiO 2

Al 2 o 3

CaO MgO Fe 2 o 3

Na 2 O+K 2 o

Baiyun Obo Iron Tailings...

Embodiment 3

[0061] A solid waste-based nanocrystalline cluster magnetic glass-ceramic is prepared by the method of high-temperature melting-spontaneous nucleation-lower temperature crystallization, and the specific steps are as follows:

[0062] (1) Preparation of the mixture:

[0063] Design B 2 o 3 -Fe 2 o 3 -SiO 2 It is a basic glass formula, in which the weight percentage of each component is: SiO 2 50.6%, Fe 2 o 3 30%, B 2 o 3 15.7%, MgO+CaO 0.3%, Na 2 O+K 2 O 0.4%, Al 2 o 3 3%.

[0064] Using waste borate glassware as the main raw material (see Table 4 for its main components), with appropriate amount of auxiliary materials such as quartz sand and ferric oxide, design B 2 o 3 -Fe 2 o 3 -SiO 2 It is a glass formula, weigh the raw materials, and mix them evenly.

[0065] Table 4 The main chemical components of waste borate glassware (wt.%)

[0066] SiO 2

B 2 o 3

CaO MgO Na 2 O+K 2 o

waste borate glassware 60~80 15~30 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com