Preparation method and application of lithium vanadium fluorophosphate

A technology for compounding lithium vanadium fluorophosphate and vanadium source is applied in the preparation/purification of carbon, chemical instruments and methods, phosphorus compounds, etc., and can solve problems such as side reactions and reduction of product purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

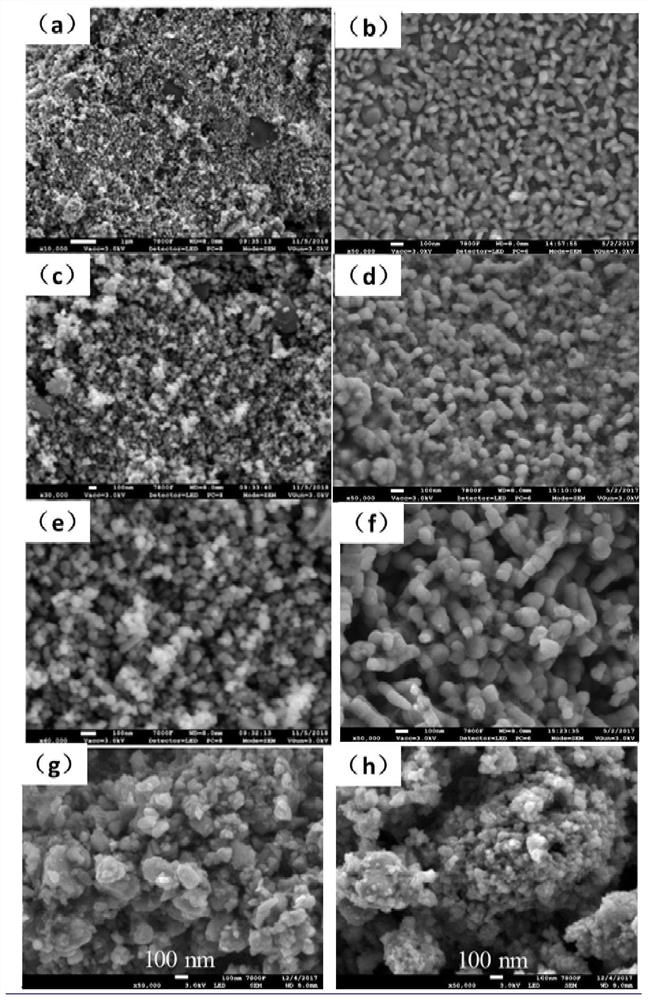

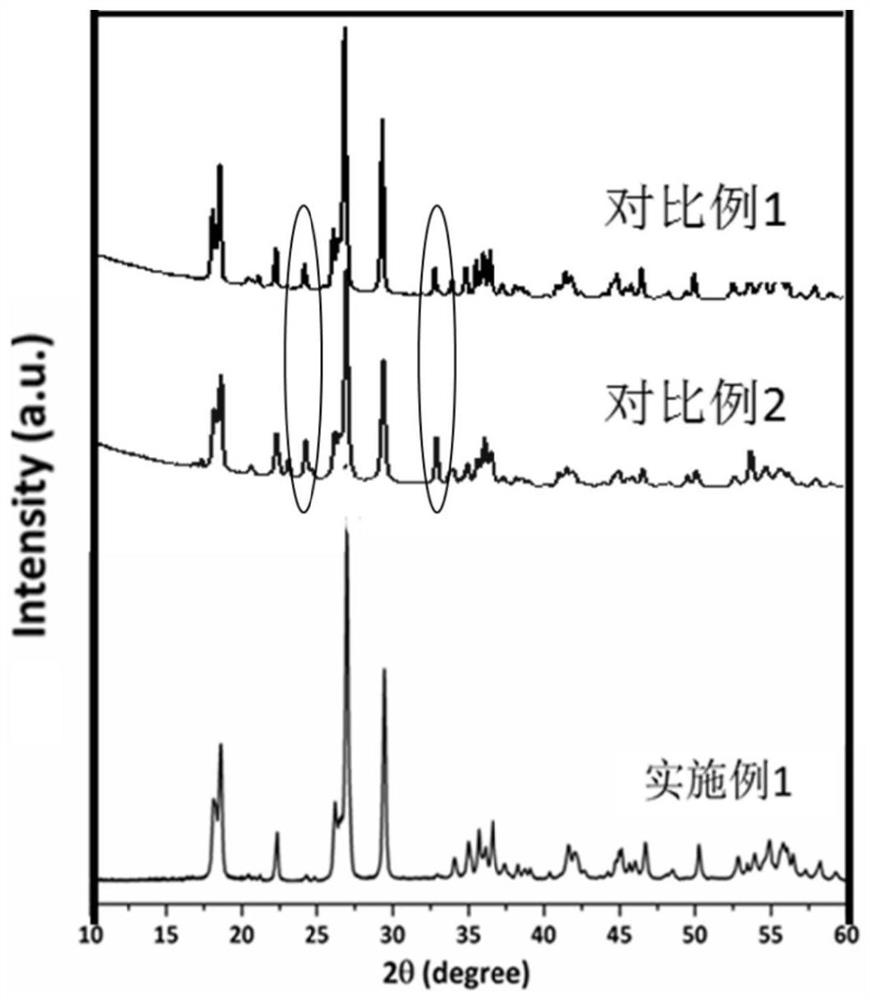

[0029] VPO 4 Preparation of LiVPO as precursor by @C 4 F@C

[0030] Mix 0.05mol ammonium metavanadate, 0.05mol ammonium dihydrogen phosphate, and an appropriate amount of citric acid in a beaker filled with 200ml of water, and stir mechanically at 80°C for 10 hours to obtain mixed solution A; the mass of citric acid is ammonium metavanadate 40% of mass;

[0031] Put the prepared mixed solution A in an oven at 100 degrees to dry for 12 hours, take it out and pulverize it, put it in a tube furnace with an argon atmosphere at 750 ° C for 6 hours at a constant temperature, take it out and grind it to obtain black carbon-composite vanadium phosphate Powder (VPO 4 @C);

[0032] The resulting VPO 4 @C is mixed with 0.05mol ammonium fluoride, 0.05mol lithium hydroxide, and 80ml water to obtain a mixed solution B, and the mixed solution B is placed in a 180-degree reaction kettle for 48 hours of solvothermal reaction, suction filtered, and dried. LiVPO can be obtained by grinding...

Embodiment 2

[0034] V 2 o 3 Preparation of LiVPO as precursor by @C 4 F@C

[0035] Put 0.05mol ammonium metavanadate and an appropriate amount of citric acid into a beaker containing 200ml of water and mix them, and mechanically stir at 80°C for 10 hours to obtain a mixed solution A; the mass of citric acid is 50% of the mass of ammonium metavanadate;

[0036] Put the prepared mixed solution A in a 100-degree oven to dry for 12 hours, take it out and pulverize it, put it in a tube furnace with an argon atmosphere at 750 ° C for 6 hours, take it out and pulverize it to obtain black V 2 o 3 @C powder;

[0037] The resulting V 2 o 3 Mix @C with 0.05mol ammonium fluoride, 0.05mol ammonium dihydrogen phosphate, 0.05mol lithium hydroxide, and 80ml water to obtain a mixed solution B, and place the mixed solution B in a reactor at 180 degrees for 48 hours of solvothermal reaction , suction filtration, drying, and grinding to obtain LiVPO 4 F@C powder;

Embodiment 3

[0039] VPO 4 @C is the precursor to prepare LiVPO 4 F@C

[0040] Mix 0.05mol ammonium metavanadate, 0.05mol ammonium dihydrogen phosphate, and an appropriate amount of citric acid in a beaker filled with 200ml of water, and stir mechanically at 80°C for 10 hours to obtain mixed solution A; the mass of citric acid is ammonium metavanadate 40% of mass;

[0041] Put the prepared mixed solution A in an oven at 100 degrees to dry for 12 hours, take it out and pulverize it, put it in a tube furnace with an argon atmosphere at 600 ° C for 10 hours at a constant temperature, take it out and pulverize it to obtain black carbon-composite vanadium phosphate Powder (VPO 4 @C);

[0042] The resulting VPO 4@C is mixed with 0.05mol ammonium fluoride, 0.05mol lithium hydroxide, and 80ml water to obtain a mixed solution B, and the mixed solution B is placed in a 180-degree reaction kettle for 48 hours of solvothermal reaction, suction filtered, and dried. LiVPO can be obtained by grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com