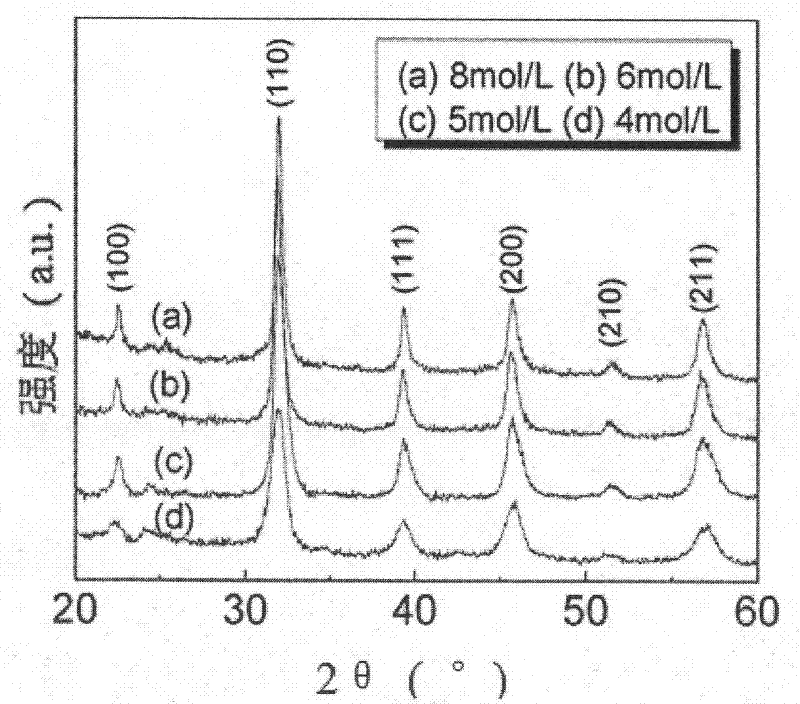

Preparation method of nano strontium barium titanate powder

A nano-titanium and barium strontium technology, which is applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of uneven distribution, impure crystal phase, and large particle size of barium strontium titanate powder, and achieve uniform particle size distribution. , The effect of improving crystal phase purity and avoiding grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

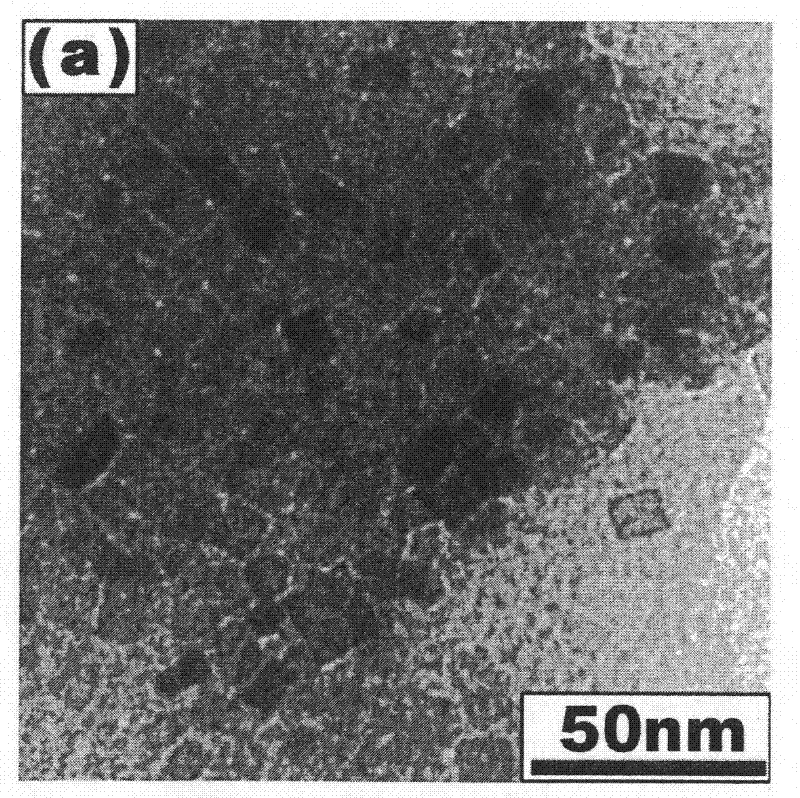

Embodiment 1

[0017] Example 1, will analyze pure grade white Ba(Ac) 2 0.75Mol / L, crystalline Sr(Ac) 2 1 / 2H 2 O0.5mol / L, 5mL of distilled water, 4mol / L of sodium hydroxide, 1.0g of sodium oleate, 15mL of oleic acid, 10mL of butanol and 1.25mol / L of n-tetrabutyl titanate are added to the stainless steel hydrothermal heat of the Teflon liner Kettle, and then gently moved to a hydrothermal furnace, heated at 160 ° C for 24h. The reacted mixed solution was naturally cooled to room temperature, the supernatant was removed, and the reaction precipitate was washed out with 25 ml of ethanol. The amount of ethanol should be such that the precipitate could be washed out. Centrifuge, then dissolve the precipitate with cyclohexane, the amount of cyclohexane should be just enough to dissolve the precipitate. Add 35ml of ethanol to the solution, the amount of ethanol should be such that the amount of precipitate is no longer increased, and the nanocrystalline BST precipitate will be produced at room t...

Embodiment 2

[0021] Example 2, will analyze pure grade white Ba(Ac) 2 1.5Mol / L, crystalline Sr(Ac) 2 1 / 2H 2 O 1mol / L, 10mL of distilled water, 5mol / L of sodium hydroxide, 2.0g of sodium oleate, 30mL of oleic acid, 20mL of butanol and 2.5mol / L of n-tetrabutyl titanate are added to a stainless steel hydrothermal kettle with a Teflon liner , and then gently moved to a hydrothermal furnace, heated at 100 ° C for 25h. The reacted mixed solution was naturally cooled to room temperature, the supernatant was removed, and the reaction precipitate was washed out with 30 ml of ethanol. The amount of ethanol should be such that the precipitate could be washed out. Centrifuge, then dissolve the precipitate with cyclohexane, the amount of cyclohexane should be just enough to dissolve the precipitate. Add 40ml of ethanol to the solution, and the amount of ethanol should be such that the amount of precipitates is no longer increased, and nanocrystalline BST precipitates are produced at room temperature...

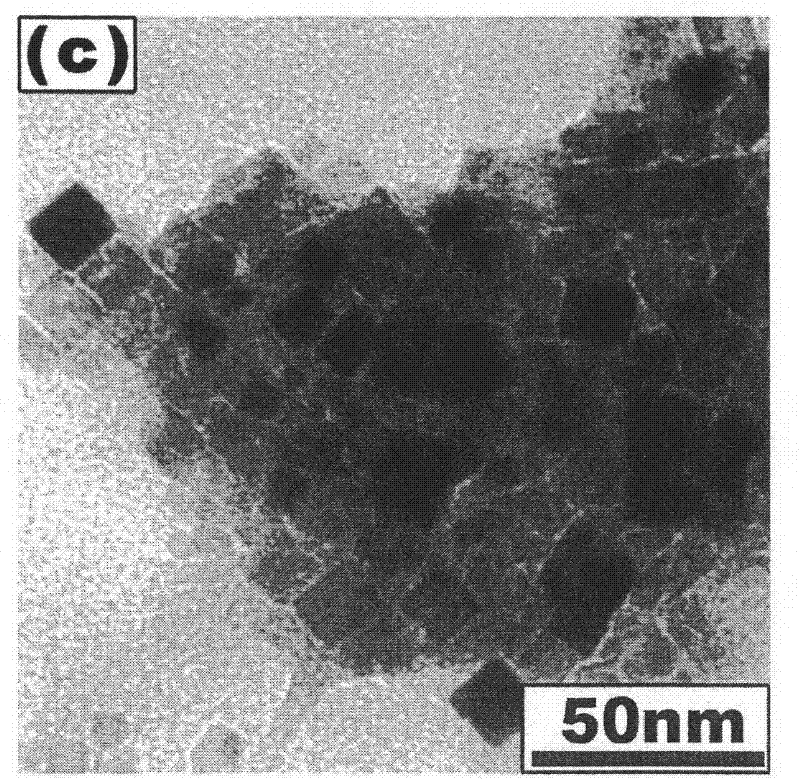

Embodiment 3

[0024] Example 3, will analyze the white Ba(Ac) of pure grade 2 2.25Mol / L, crystalline Sr(Ac) 2 1 / 2H 2 O1.5mol / L, without CO 2 Add 15mL of distilled water, 6mol / L sodium hydroxide, 3.0g sodium oleate, 45mL oleic acid, 30mL butanol and 3.75mol / L n-tetrabutyl titanate into the stainless steel hydrothermal kettle with Teflon liner, and then gently Moved to a hydrothermal furnace and heated the reaction at 150°C for 18h. The reacted mixed solution was naturally cooled to room temperature, the supernatant was removed, and the reaction precipitate was washed out with 40 ml of ethanol. The amount of ethanol should be such that the precipitate could be washed out. Centrifuge, then dissolve the precipitate with cyclohexane, the amount of cyclohexane should be just enough to dissolve the precipitate. Add 45ml of ethanol to the solution, and the amount of ethanol should be such that the amount of precipitates is no longer increased, and nanocrystalline BST precipitates are produced a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com