A repair method of carbon composite vanadium phosphate

A remediation method and carbon composite technology, applied in chemical instruments and methods, phosphorus compounds, structural parts, etc., can solve problems such as inefficient remediation methods, improve reusability and economic value, avoid waste water pollution, and crystal phase purity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment discloses a preparation and restoration method of carbon-composite vanadium phosphate. Include the following steps:

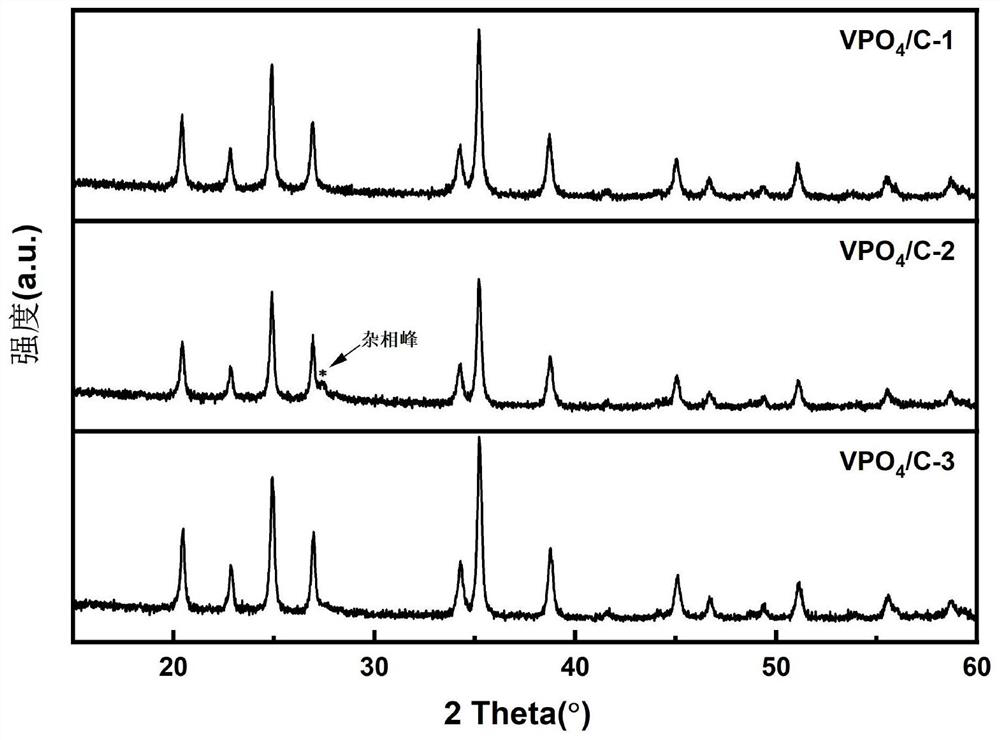

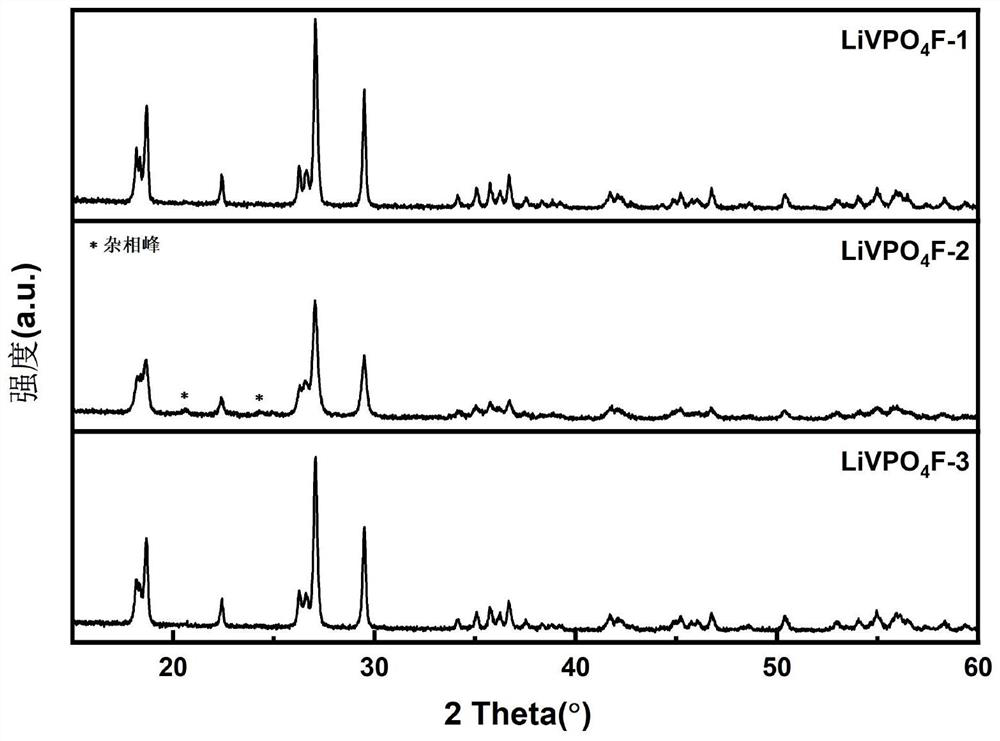

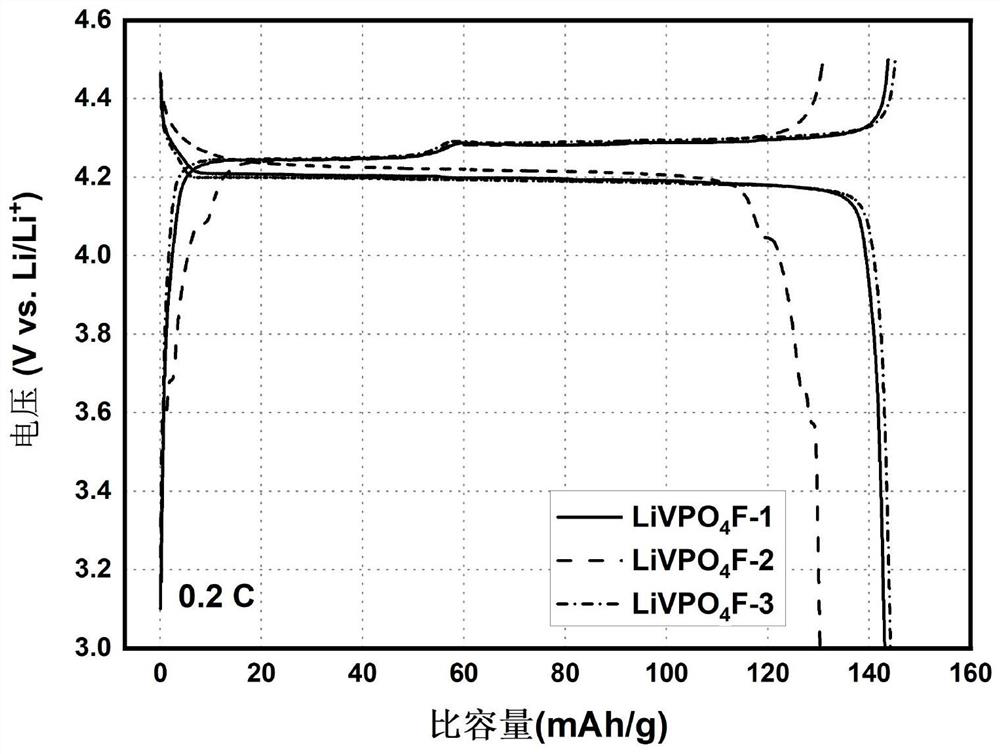

[0046] New Carbon Composite Vanadium Phosphate (VPO 4 / C-1): 45g of glucose monohydrate, 100g of vanadium pentoxide, and 33g of oxalic acid were added to 200mL aqueous solution in sequence, and mechanically stirred at 60°C for 30 minutes until the glucose was completely dissolved, and then the temperature was raised to 90°C. After the temperature stabilizes, slowly pour 145g of industrial phosphoric acid into the solution. After the solution forms a uniform dark green viscous liquid, transfer it to an oven and dry it at 110°C. Then the dried sample is crushed and calcined at a high temperature under the protection of nitrogen. , the calcination conditions are 500°C for 3h, 850°C for 3h, cooling to room temperature and crushing to obtain the new carbon-composite vanadium phosphate product 1.

[0047] In the example, in order to highlight...

Embodiment 2

[0055] This embodiment discloses a preparation and restoration method of carbon-composite vanadium phosphate. Include the following steps:

[0056] New Carbon Composite Vanadium Phosphate (VPO 4 / C-1): Add 30g of sucrose, 130g of ammonium metavanadate, and 50g of citric acid to 200mL of aqueous solution in sequence, mechanically stir at 70°C for 30 minutes, then raise the temperature to 93°C, and pour into the solution after the temperature stabilizes. Slowly pour 145g of industrial phosphoric acid into the solution, and after the solution forms a uniform blue viscous liquid, transfer it to an oven for drying at 110°C, then pulverize the dried sample and perform high-temperature calcination under the protection of nitrogen. The calcination condition is 500 Calcined at ℃ for 4 hours, and then calcined at 850℃ for 5 hours to obtain the new carbon-composite vanadium phosphate product 1.

[0057] Failed Carbon Composite Vanadium Phosphate (VPO 4 / C-2) The preparation method is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com