A kind of vanadium sodium fluorophosphate coated sodium ferric phosphate pyrophosphate composite material and its preparation method and application

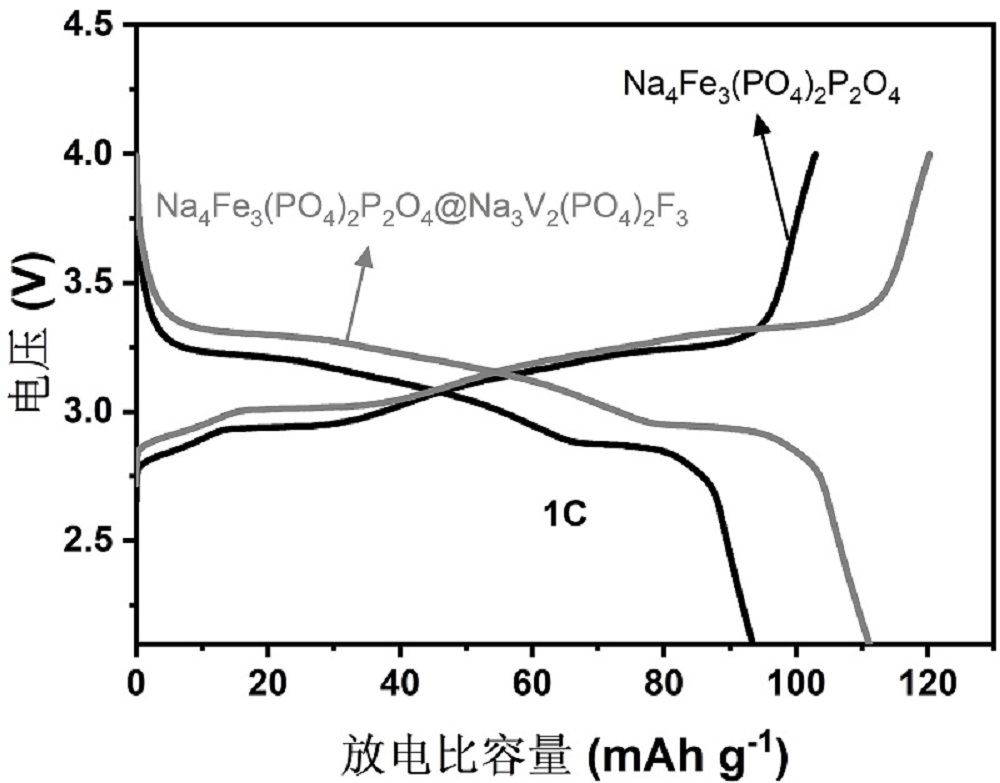

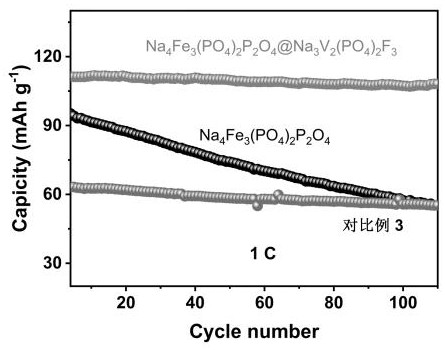

A technology for coating sodium ferric phosphate pyrophosphate with sodium vanadium fluorophosphate, and coating sodium ferric phosphate pyrophosphate with sodium vanadium phosphate is applied in the field of battery cathode material preparation, and can solve the problem of poor cycle stability and poor phase transition of sodium ferric phosphate pyrophosphate materials. Stability, slow ion diffusion and other problems, to achieve the effect of good phase stability, improved thermal stability and chemical stability, and fast ion transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

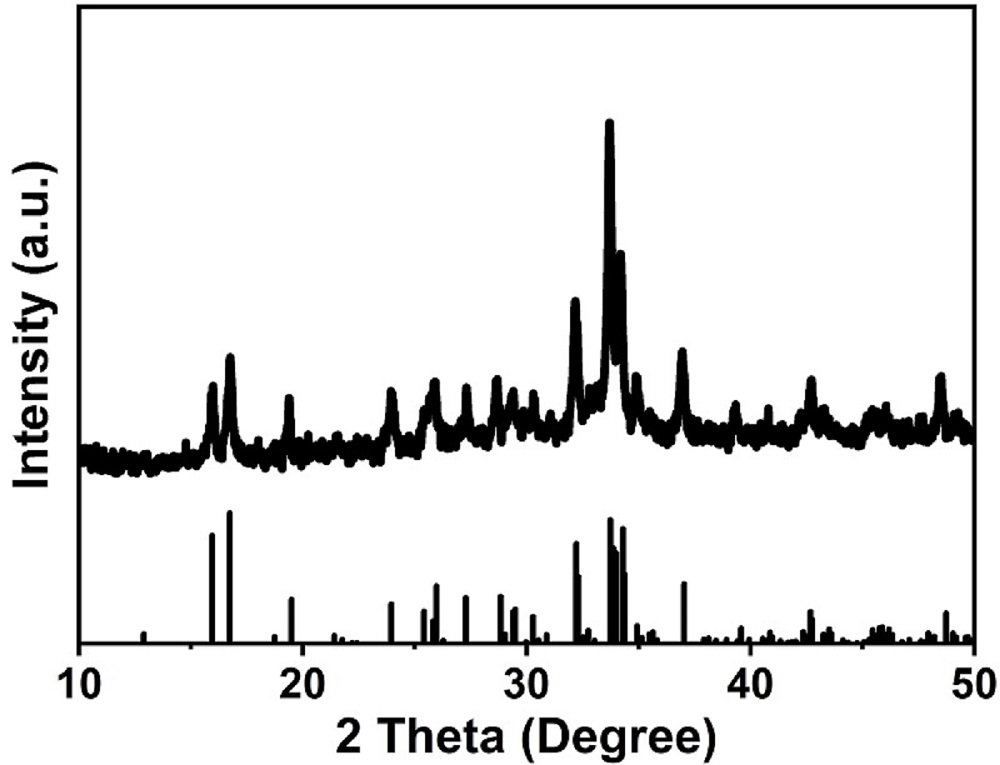

[0041] A preparation method of sodium ferric pyrophosphate composite material coated with sodium vanadium fluorophosphate, comprising the following steps:

[0042] S1. Disperse 0.01mol sodium pyrophosphate, 0.03mol ferrous oxalate, 0.02mol ammonium dihydrogen phosphate and 0.01mol citric acid in 100mL 200g / L tetraethylene glycol aqueous solution, stir at 500r / min speed for 3h and mix well Transfer to the reaction kettle, conduct hydrothermal reaction at 200°C for 5h, after the reaction is completed, filter and freeze-dry in vacuum at -20°C for 20h to obtain the precursor of sodium iron phosphate pyrophosphate;

[0043] S2, the sodium ferric pyrophosphate precursor obtained in step S1 and 3mmol sodium fluoride, 2mmol ammonium metavanadate, 2mmol ammonium dihydrogen phosphate and 0.5mmol citric acid are dispersed in the polyethylene glycol aqueous solution of 100mL 200g / L, After stirring at 500 r / min for 3 hours, the mixture was transferred to the reaction kettle, and the hydrot...

Embodiment 2

[0050] A preparation method of sodium ferric pyrophosphate composite material coated with sodium vanadium fluorophosphate, comprising the following steps:

[0051] S1. Disperse 0.01mol sodium pyrophosphate, 0.031mol ferrous oxalate, 0.021mol ammonium dihydrogen phosphate and 0.01mol citric acid in 100mL 200g / L tetraethylene glycol aqueous solution, stir at 500r / min speed for 3h and mix well Transfer to the reaction kettle, conduct hydrothermal reaction at 200°C for 5h, after the reaction is completed, filter and freeze-dry in vacuum at -20°C for 20h to obtain the precursor of sodium iron phosphate pyrophosphate;

[0052] S2, the sodium ferric pyrophosphate precursor obtained in step S1 and 3mmol sodium fluoride, 2.1mmol ammonium metavanadate, 2.05mmol ammonium dihydrogen phosphate and 0.5mmol citric acid are dispersed in 100mL 200g / L polyethylene glycol aqueous solution , stir at a speed of 500 r / min for 3 hours and mix well, then transfer to the reaction kettle, and conduct h...

Embodiment 3

[0057] A preparation method of sodium ferric pyrophosphate composite material coated with sodium vanadium fluorophosphate, comprising the following steps:

[0058] S1. Disperse 0.01 mol of sodium pyrophosphate, 0.031 mol of ferrous oxalate, 0.021 mol of ammonium dihydrogen phosphate and 0.01 mol of citric acid in 100 mL of 200 g / L tetraethylene glycol aqueous solution, and stir for 1 h at a speed of 200 r / min. Transfer to the reaction kettle, conduct hydrothermal reaction at 180°C for 3h, after the reaction is completed, filter and freeze-dry in vacuum at -20°C for 10h to obtain the precursor of sodium iron phosphate pyrophosphate;

[0059] S2, the sodium ferric phosphate precursor obtained in step S1 and 3mmol sodium fluoride, 2.1mmol ammonium metavanadate, 2mmol ammonium dihydrogen phosphate and 0.5mmol citric acid are dispersed in the polyethylene glycol aqueous solution of 100mL 200g / L , stirred at a speed of 200r / min for 1h and mixed, then transferred to the reaction kett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com