Synthetic rare earth doped nitric oxide fluorescent powder and preparation method thereof

A nitrogen oxide, rare earth doping technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor aging resistance of phosphors, low crystal phase purity of products, harsh synthesis conditions, etc., and achieve strong operability , Avoid the formation of nitrogen oxides, the effect of wide process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

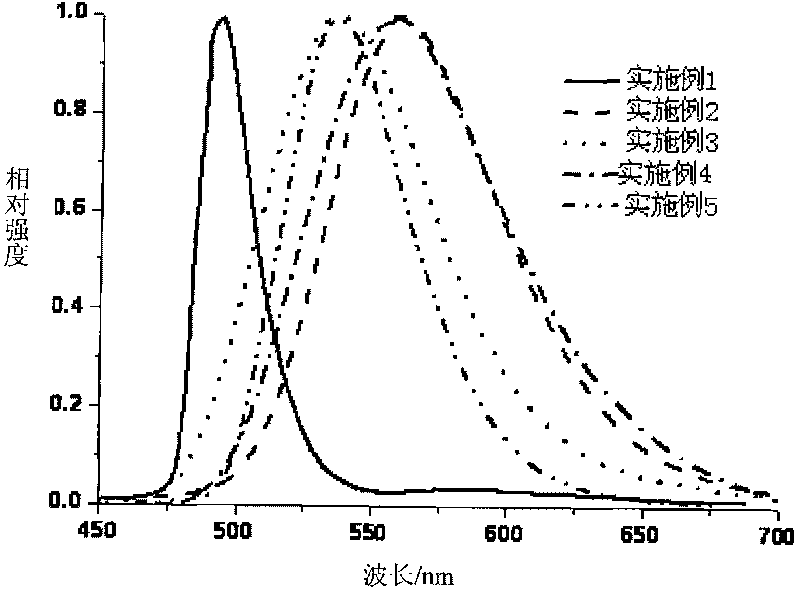

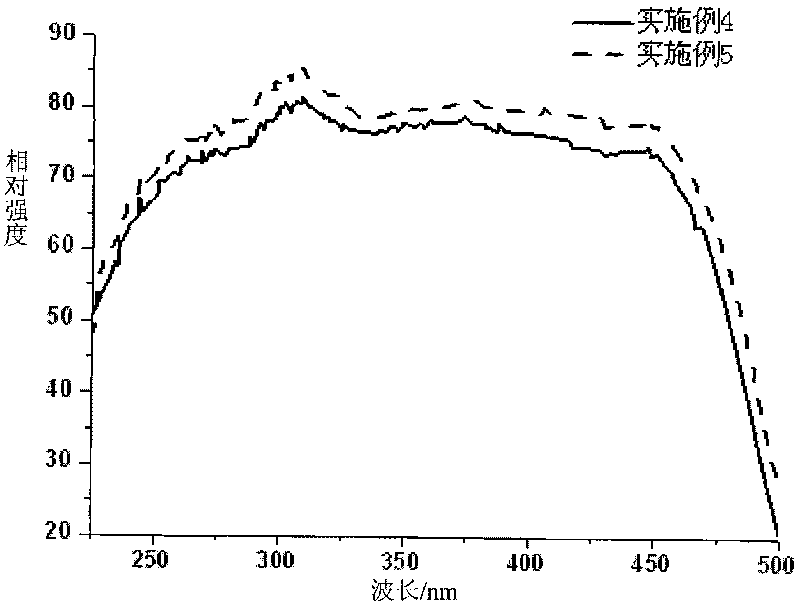

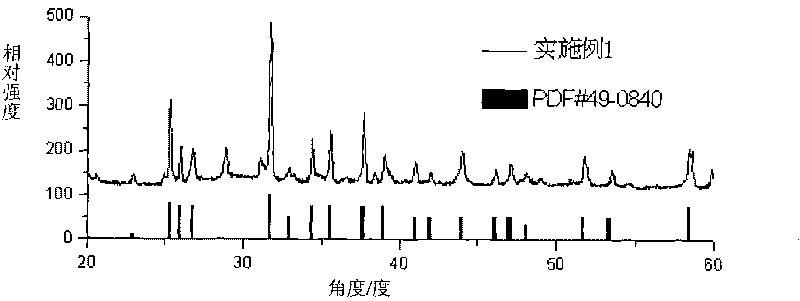

Embodiment 1

[0030] According to Ba 1.96 SiO 4 : 0.04Eu weighed BaCO 3 3.868g, SiO 2 0.601g, Eu 2 o 3 0.070g and 2wt% reaction aid NH 4 Cl was mixed and fully ground (ball milled) and then placed in an alumina crucible, and the crucible was placed in a tube furnace, under H 2 Ba 1.96 SiO 4 :0.04Eu. According to Ba 0.98 Si 2 o 2 N 2 o 4 : The stoichiometric ratio of each element of 0.02Eu will be obtained Ba 1.96 SiO 4 : 0.04Eu ground and sieved and then mixed with 1.823g α-Si 3 N 4 And 3wt% reaction aid NH 4 Cl is mixed and ground (ball milled) and put into a molybdenum crucible, and the crucible is moved into a high-temperature tube furnace. 2 / H 2 Sinter at 1500°C for 3 hours in the atmosphere, cool to room temperature, take out, grind and sieve, wash and dry with ethanol to obtain blue-green phosphor Ba 0.98 Si 2 o 2 N 2 o 4 :0.02Eu.

Embodiment 2

[0032] According to Ca 2 SiO 4 Weigh CaO1.123g, SiO 2 0.601g was mixed and fully ground (ball milled) and then placed in an alumina crucible, placed in a tube furnace, sintered at 950°C for 5 hours in an Ar reducing atmosphere, then cooled to room temperature to obtain Ca 2 SiO 4 . According to Ca 0.97 Si 2 o 2 N 2 : The stoichiometric ratio of 0.03Eu elements will result in Ca 2 SiO 4 Grinding and sieving with α-Si 3 N 4 0.696g, Eu 2 o 3 0.070g and 1wt% reaction aid CaF 2 After mixing and grinding (ball milling), put it into a molybdenum crucible, and move the crucible into a high-temperature tube furnace. 2 / H 2Sinter at 1600°C for 3 hours in the atmosphere, cool to room temperature, take out, grind and sieve, wash and dry with ethylene glycol to obtain yellow-green phosphor Ca 0.97 Si 2 o 2 N 2 : 0.03Eu.

Embodiment 3

[0034] According to Sr 1.92 Li 0.04 SiO 4 : 0.04Eu, 0.04Ce weighed SrCO 3 2.834g, SiO 2 0.601g, Eu 2 o 3 0.070g, Ce(NO 3 )·6H 2 O 0.174g and charge compensator Li 2 CO 3 0.015g, after mixing and fully grinding (ball milling), put it in an alumina crucible, place the crucible in a tube furnace, and 2 / H 2 Sintered at 1500°C for 2 hours in a reducing atmosphere and then cooled to room temperature to obtain Sr 1.92 Li 0.04 SiO 4 : 0.04Eu, 0.04Ce. According to Sr 0.96 Li 0.02 Si 2 o 2 N 2 : 0.02Eu, the stoichiometric ratio of each element of 0.02Ce will be gained Sr 1.92 Li 0.04 SiO 4 : 0.04Eu, 0.04Ce ground and sieved with 1.425g α-Si 3 N and 1wt% reaction aid SrF 2 After mixing and grinding (ball milling), put it into a molybdenum crucible, and move the crucible into a high-temperature tube furnace. 2 Sinter at 1400°C for 5 hours in a protective atmosphere, cool to room temperature, take out, grind and sieve, wash and dry with ethanol aqueous solution to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com