Carbon-coated LiVPO4F positive electrode material as well as preparation and application thereof

A cathode material and carbon coating technology, applied in the field of carbon-coated LiVPO4F cathode material preparation, can solve problems such as difficulty in synthesizing pure phase LiVPO, achieve excellent electrochemical performance, improve electronic conductivity, and improve the effect of crystal phase purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

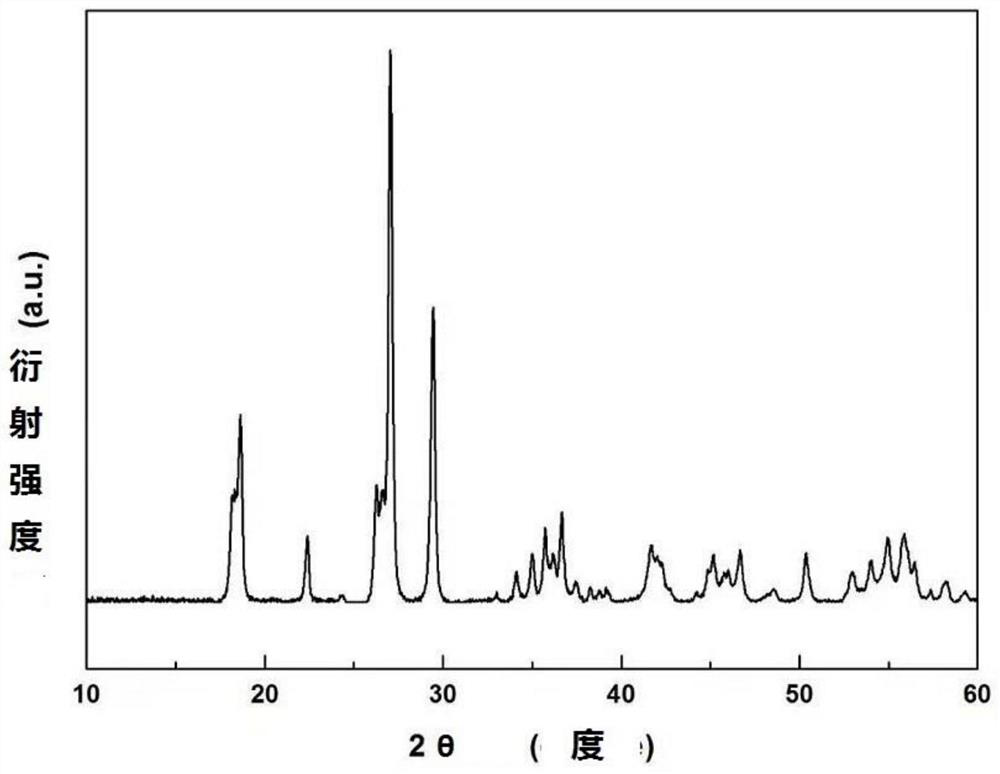

[0028] Embodiment 1: Taking oxalic acid, vanadium pentoxide, ammonium dihydrogen phosphate, lithium fluoride, glucose, and PTFE as initial raw materials. First weigh 3.396g of oxalic acid and dissolve it in 50ml of deionized water, stir the oxalic acid solution in an 80°C water bath for 0.5h, then weigh 2.129g of vanadium pentoxide and add it to the above oxalic acid solution and continue stirring for 0.5h; then weigh 1.345g of ammonium dihydrogen phosphate, 0.318g of lithium fluoride and 0.5g of glucose were added to the above solution, and the stirring was continued for 6h to obtain a blue colloidal liquid, which was dried at 120°C for 24h; After pre-sintering at 350 °C for 5 h in the atmosphere, it was mixed with 3.792 g of PTFE and sintered at 800 °C for 5 h to obtain a pure phase of carbon-coated LiVPO 4 F positive electrode material, the particle size is 0.5-3 microns, the obtained product is a pure phase after XRD analysis, and the carbon mass content in the material is...

Embodiment 2

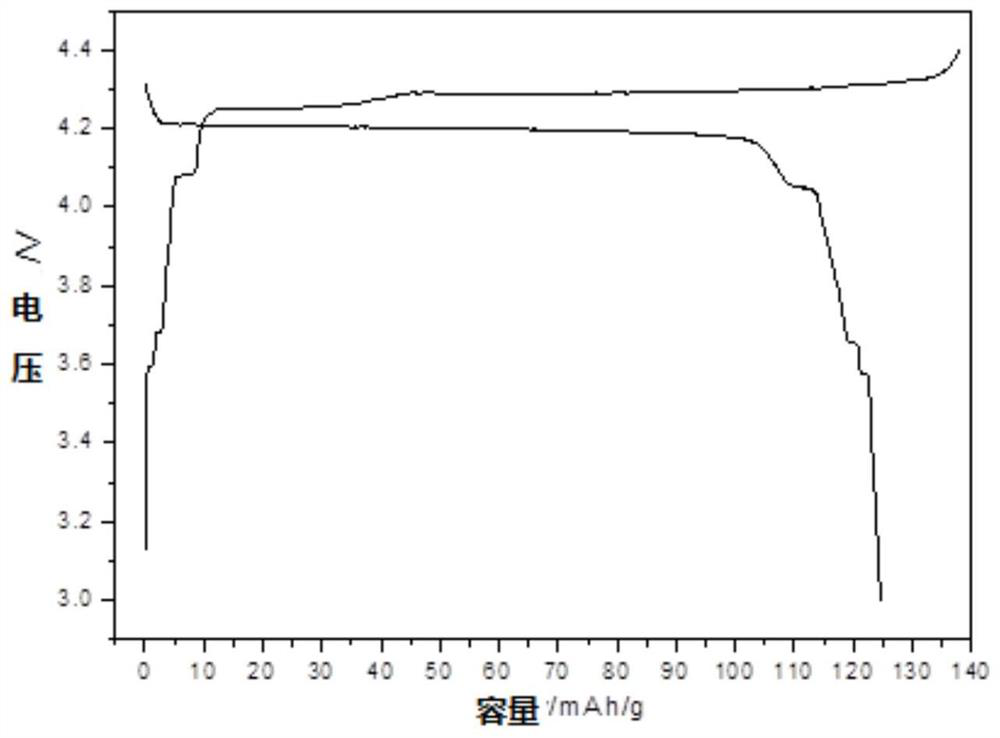

[0029] Embodiment 2: Taking oxalic acid, ammonium metavanadate, phosphoric acid, lithium fluoride, PVDF, and glucose as initial raw materials. First weigh 3.396g of oxalic acid and dissolve it in 50ml of deionized water, stir the oxalic acid solution in an 80°C water bath for 0.5h, then weigh 1.368g of ammonium metavanadate and add it to the above oxalic acid solution and continue stirring for 0.5h; then weigh 1.147g of phosphoric acid, 0.318g of lithium fluoride and 0.5g of glucose were added to the above solution, and the stirring was continued for 8h to obtain a blue colloidal liquid, which was dried at 120°C for 48h; After pre-sintering at ℃ for 8 h, it was mixed with 1.515 g of PVDF and sintered at 750 °C for 5 h to obtain a pure phase of carbon-coated LiVPO 4 F cathode material. The particle size is 0.5-3 microns. The obtained product is a pure phase after XRD analysis. The carbon content in the material is about 5%. The carbon-coated LiVPO 4 F, super P and PVDF are pr...

Embodiment 3

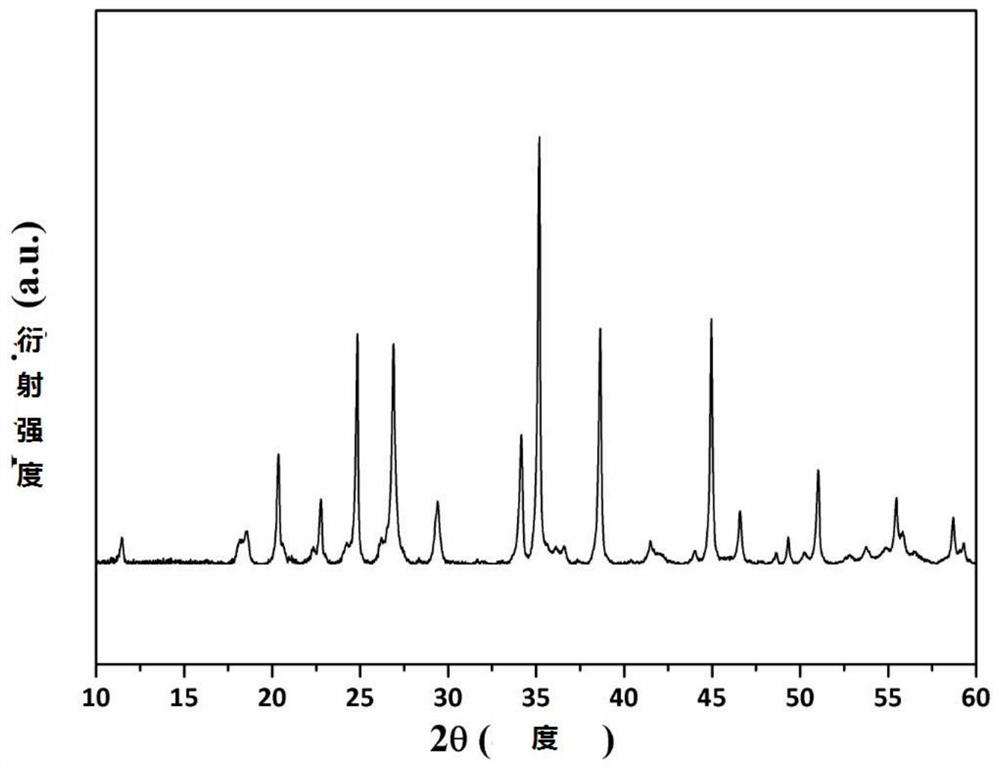

[0030] Embodiment 3: Taking oxalic acid, vanadium pentoxide, ammonium dihydrogen phosphate, lithium fluoride, and PTFE as initial raw materials. First weigh 3.396g of oxalic acid and dissolve it in 50ml of deionized water, stir the oxalic acid solution in an 80°C water bath for 0.5h, then weigh 1.368g of ammonium metavanadate and add it to the above oxalic acid solution and continue stirring for 0.5h; then weigh Add 1.345g of ammonium dihydrogen phosphate and 0.318g of lithium fluoride to the above solution, and continue to stir for 6h to obtain a blue colloidal liquid, which is dried at 120°C for 12h; the dried product is heated at 350°C under an argon atmosphere After pre-sintering for 6 h, it was mixed with 2.215 g of PTFE and sintered at 650 °C for 4 h to obtain a pure phase of carbon-coated LiVPO 4 F positive electrode material, the particle size is 0.5-3 microns, the obtained product is a pure phase after XRD analysis, and the carbon content in the material is about 5%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com