Tin and cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst as well as preparation method and application thereof

A technology of strontium titanate and solid solution, which is applied in the field of piezoelectric catalytic hydrogen production materials, can solve the problems of limited application and weak piezoelectric performance of strontium titanate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation and application of a tin, cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst comprises the following steps: S01 prepares solution A; S02 prepares solution B, and mixes solution A and solution B to obtain solution C; S03 solution C Stand still, centrifuge and dry to obtain precursor D, and precursor D is calcined to obtain a kind of tin, cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst; Wherein,

[0035] S01: Add 0.01mol tetrabutyl titanate to 50mL ethylene glycol, stir for 15min to obtain solution A;

[0036] S02: Weigh 0.007-0.01mol of Sr(OH) 2 ·8H 2 O, 0-0.0015mol Ce(NO 3 ) 3 ·6H 2 O and 0-0.0015mol of SnCl 2 Add it into 200mL deionized water, stir in a water bath at 80°C for 30min until the solid is completely dissolved to obtain solution B. Under stirring, slowly add solution B dropwise to solution A to obtain mixed solution C;

[0037]S03: Leave solution C for 3 hours, centri...

Embodiment 2

[0041] Weigh 5 mg of the tin, cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst provided in Example 1, use 5 mL of 0.05 mol / L sodium sulfite as the sacrificial agent for piezoelectric hydrogen production, and conduct the experiment in a small closed tube. Before that, pass nitrogen for 10 minutes to eliminate the interference of hydrogen in the air. Using a 40kHz 80W ultrasonic cleaner as the piezoelectric driving force, the piezoelectric hydrogen production effect of the piezoelectric hydrogen production catalyst was studied.

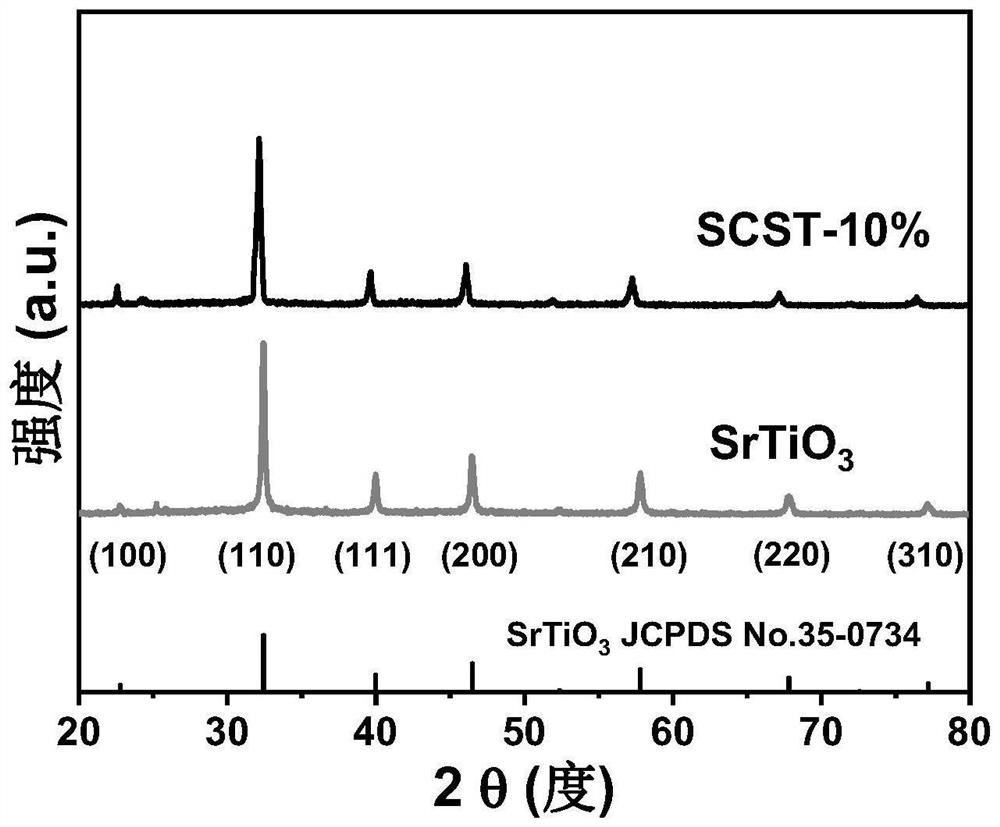

[0042] From Figure 4 As seen in the pure SrTiO 3 After 80min of ultrasonication, the hydrogen production was only 53μmol / g. With the increase of Sn and Ce content, the hydrogen production effect has been improved to varying degrees, especially the produced SCST-10%, after 80 min of ultrasonication, its hydrogen production has been greatly improved, reaching 411 μmol / g , is pure SrTiO 3 7.75 times. This is because...

Embodiment 3

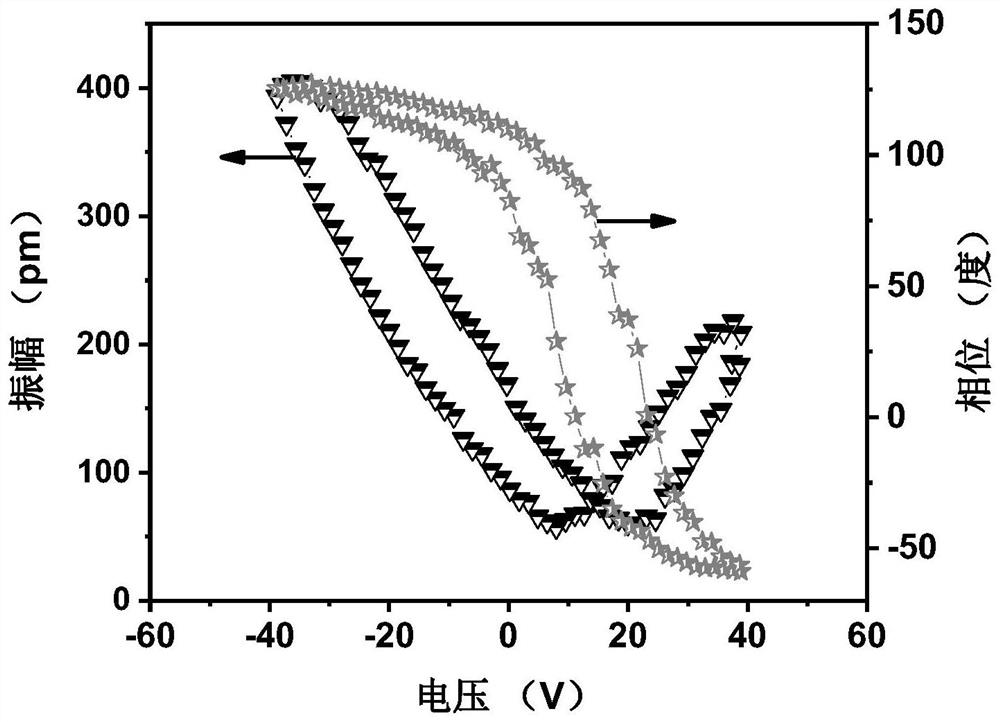

[0046] With 0.5mol / L sodium sulfate solution as conductive solution, platinum wire as counter electrode, and calomel electrode as reference electrode, the tin, cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst SrTiO provided in Example 1 was tested. 3 and Sn 0.1 Ce 0.1 Sr 0.8 TiO 3 piezoelectric response current.

[0047] Figure 6 Show Sn 0.1 Ce 0.1 Sr 0.8 TiO 3 The transient current density reaches about 4μA / cm 2 , while SrTiO 3 The piezoelectric response current is only 1.2μA / cm 2 . This indicates that the solid solution conductivity of the formed SCST-10% is much higher than that of pure SrTiO 3 , this is because the atomic radius of Sn and Ce is larger than that of Sr, resulting in stronger deformation under the same piezoelectric force, resulting in stronger polarization and stronger built-in electric field, which promotes the separation and separation of carriers. transfer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com