Preparation method and application of porous magnetoplumbite barium ferrite

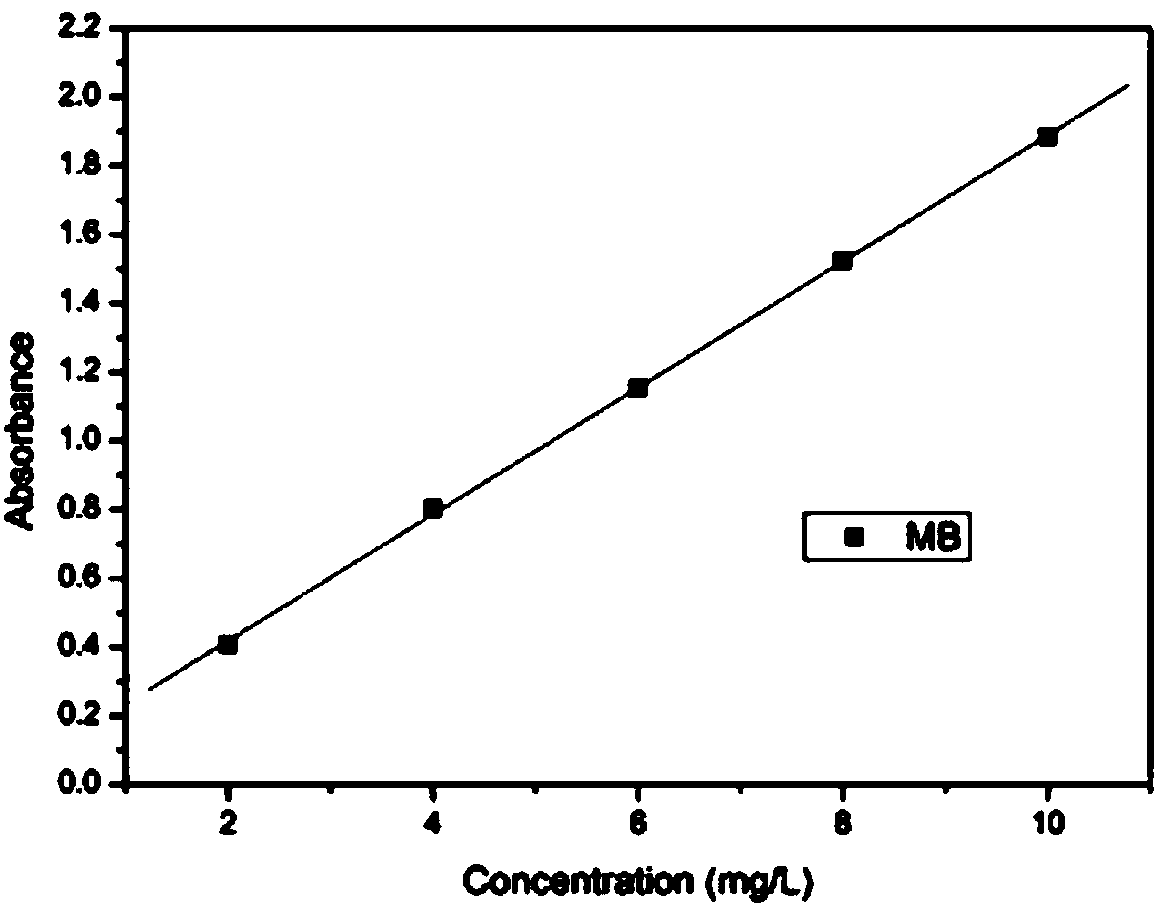

A technology of barium ferrite and magnetoplumbite, which is applied in the field of preparation of porous magnetoplumbite type barium ferrite, can solve the problems that threaten the sustainable development of society, the urgent need to treat waste water, and the high content of organic pollutants, and achieve good application The effect of high value, cheap raw materials, and low calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

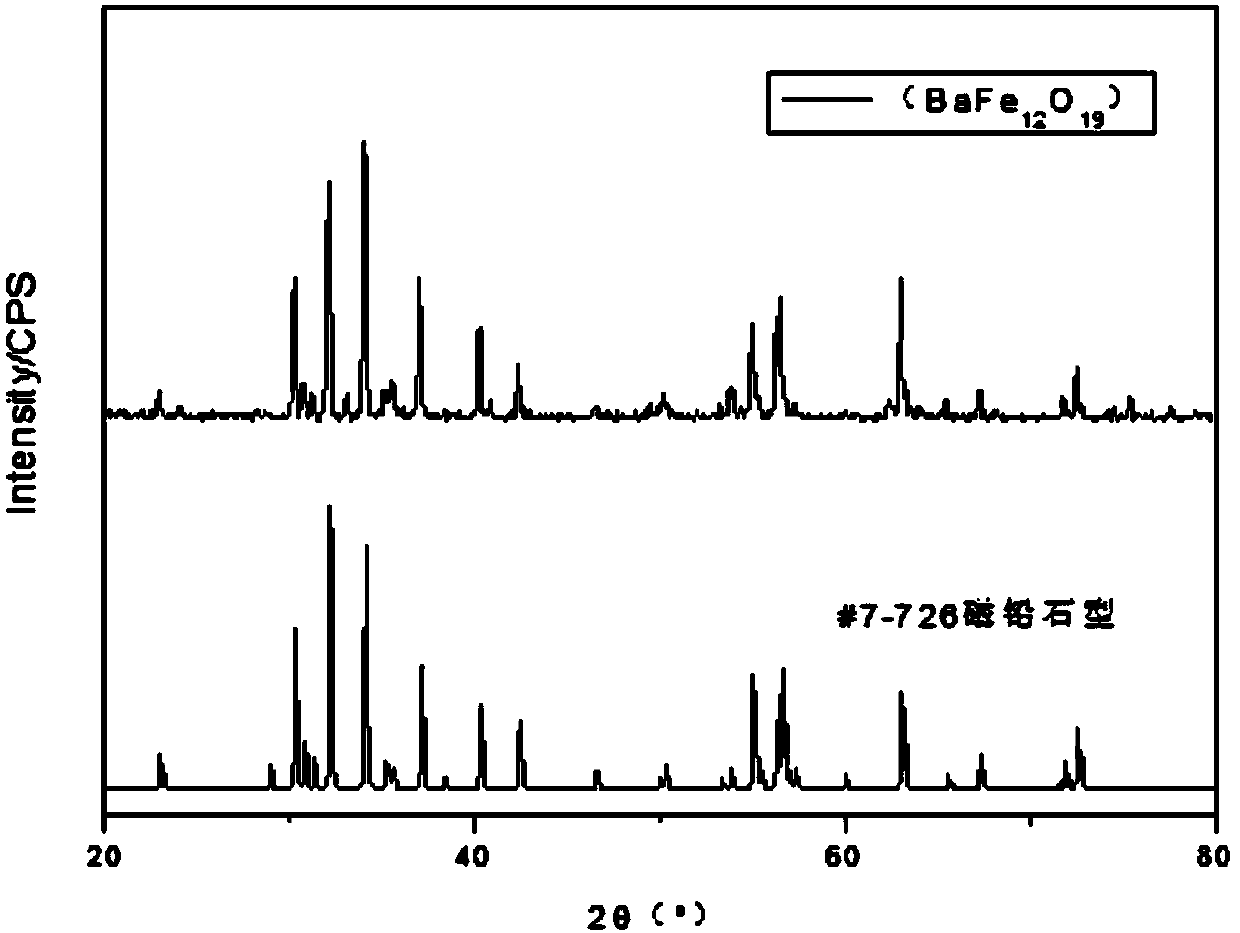

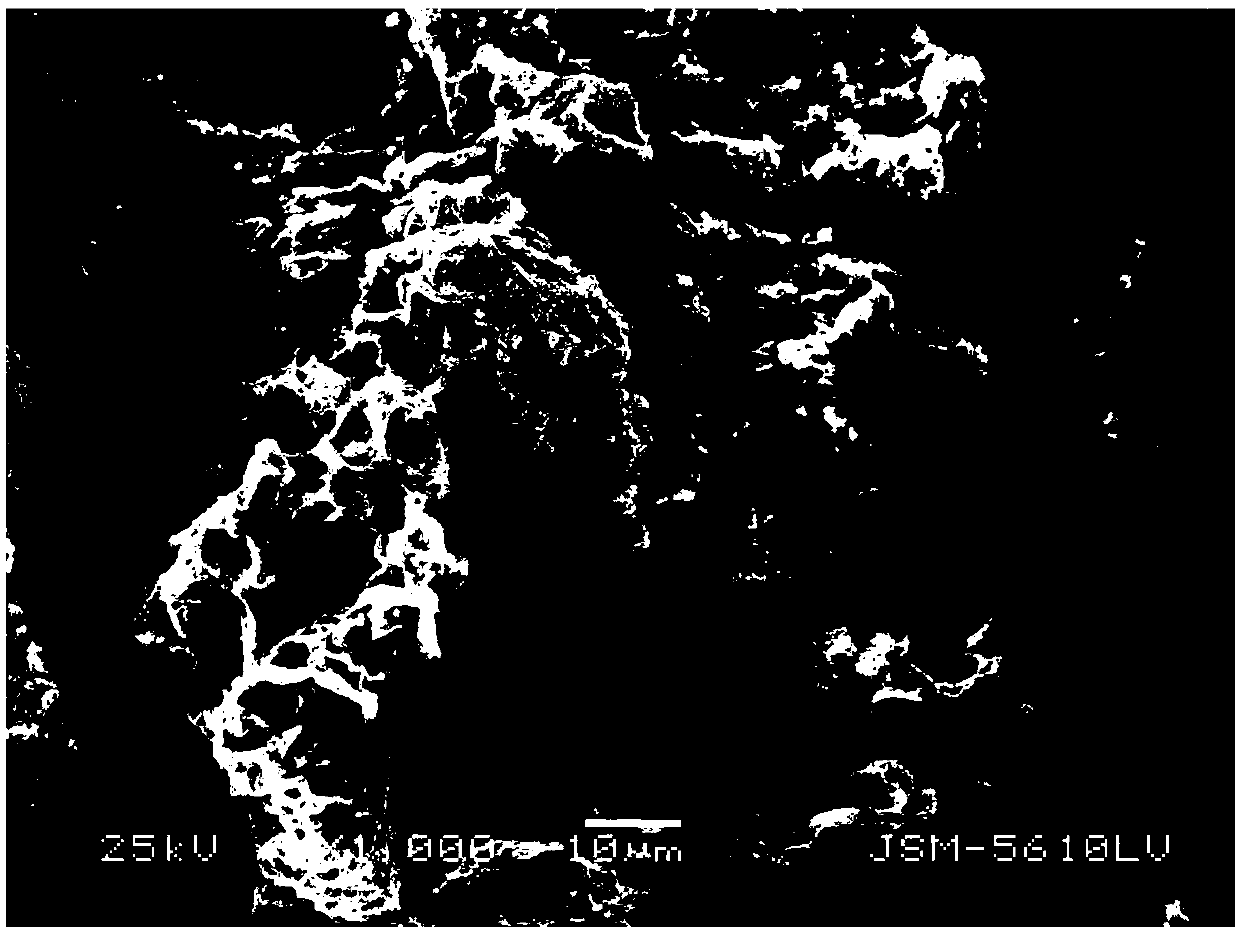

Embodiment 1

[0025] Dissolve 27.3g of citric acid in 200mL of deionized water at room temperature, then add 48.48g of ferric nitrate nonahydrate and 2.62g of barium nitrate, stir and dissolve at room temperature, and obtain a uniformly dispersed transparent solution. Ammonia water is added dropwise to the transparent solution to adjust the pH value of the solution to 8, and the solution is heated and stirred in a water bath at 90°C for 2-4 hours to evaporate the water until a gel with a water content of <10% is formed. The gel was placed in a drying oven and dried at 120° C. for 48 hours to obtain a xerogel. Ignite the xerogel with alcohol to cause self-propagating combustion, grind the burned residue, wash it with water, and dry it, then place it in a muffle furnace and heat it up to 850°C at a rate of 8°C / min for calcination for 2 hours , The product porous M-type (magnetoplumbite-type) ferrite is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com