Lithium ion positive electrode material and preparation method thereof

A cathode material, lithium ion technology, applied in the field of cathode active material of lithium ion battery and its electrochemical synthesis, can solve the problems of decreasing current efficiency, reducing the conductivity of electrolyte, accelerating the hydrolysis of transition metal ions, etc., and reducing the reaction diffusion path. Small size, shortened solid-phase reaction time, and high crystal phase purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the above-mentioned material comprises the following steps: (1) directly electrolyzing the metal in an alcohol solution containing an organic additive to form a corresponding metal alkoxide with a general formula of R-O-M. Wherein R is an alkyl group, an alkoxy group or an aromatic hydrocarbon group, and M is at least one metal element in IIIB~VIIB, VIII, IIIA, and IVA in the periodic table of elements;

[0041] (1) Mix a metal alkoxide with an aqueous solution of an alkali metal compound containing an additive to form a sol precursor xA 2 O·yM 2 o m ·zH 2 O;

[0042] (2) The sol precursor is desolvated at 120°C to 550°C to form a powdery precursor of the positive electrode material xA 2 O·yM 2 o m ;

[0043] (3) The powdery precursor is subjected to a solid-state reaction at 450° C. to 960° C. for 0.5 to 48 hours in an oxygen-free or oxygen-free atmosphere to obtain the target product.

[0044] The method for preparing lithium-ion cath...

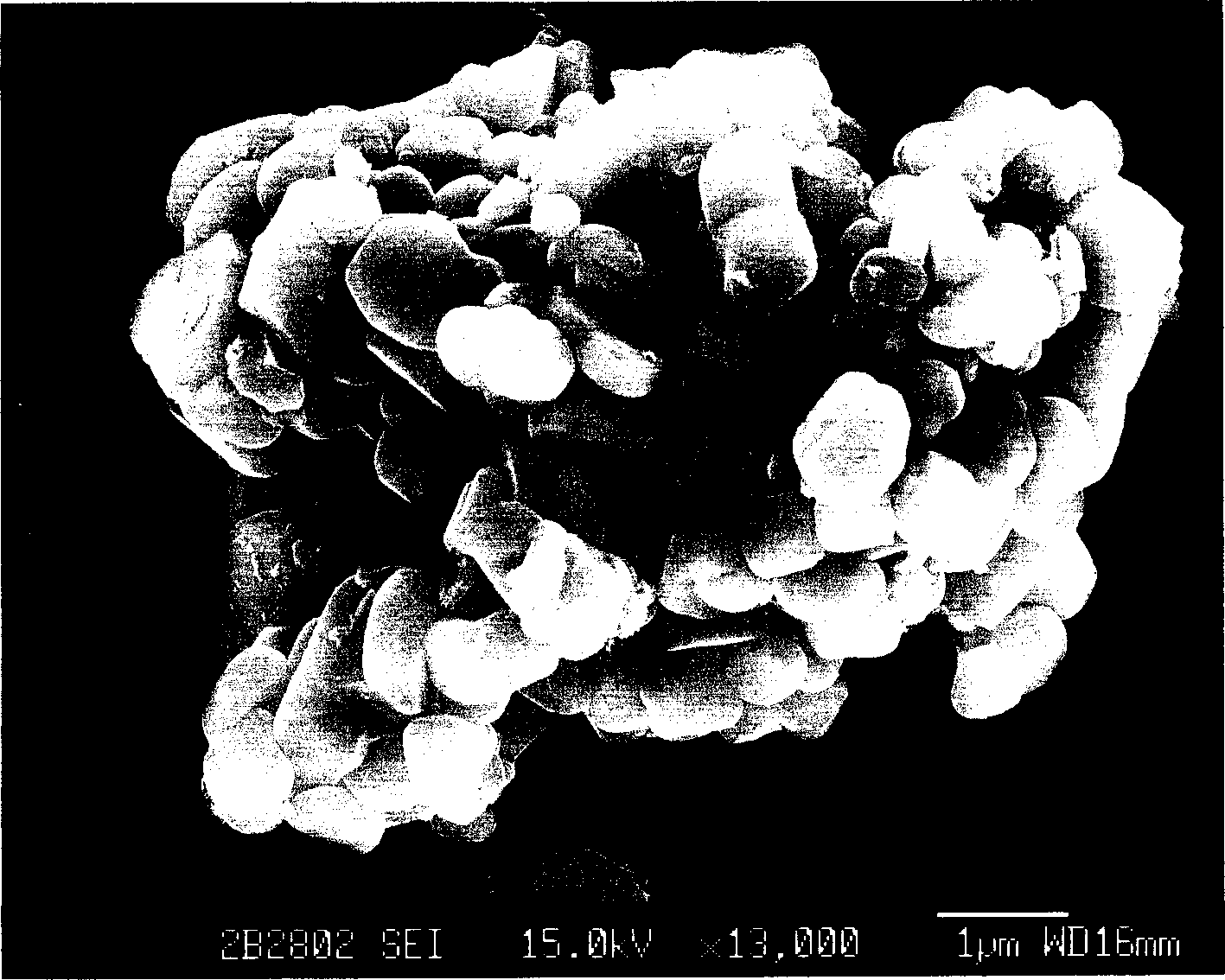

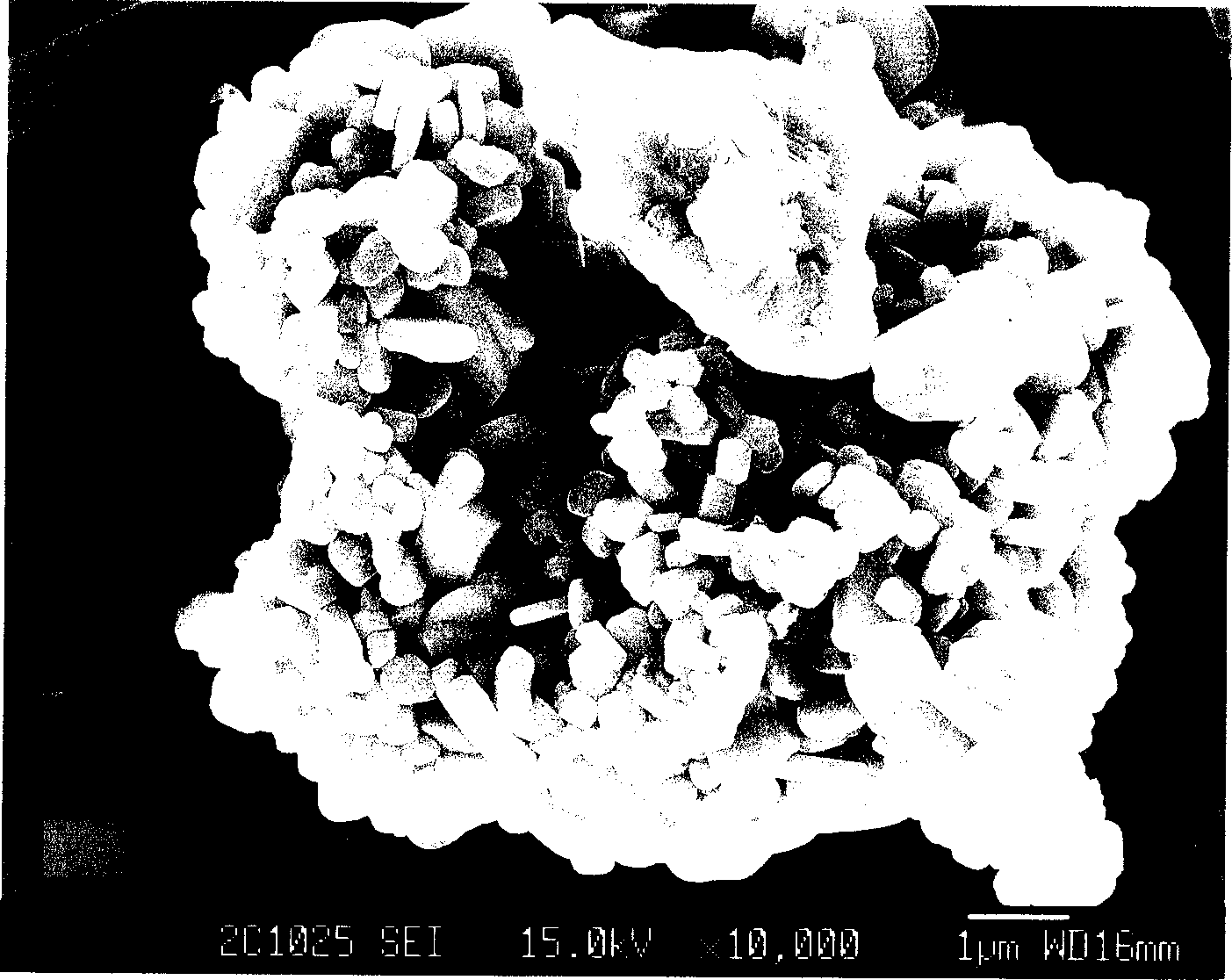

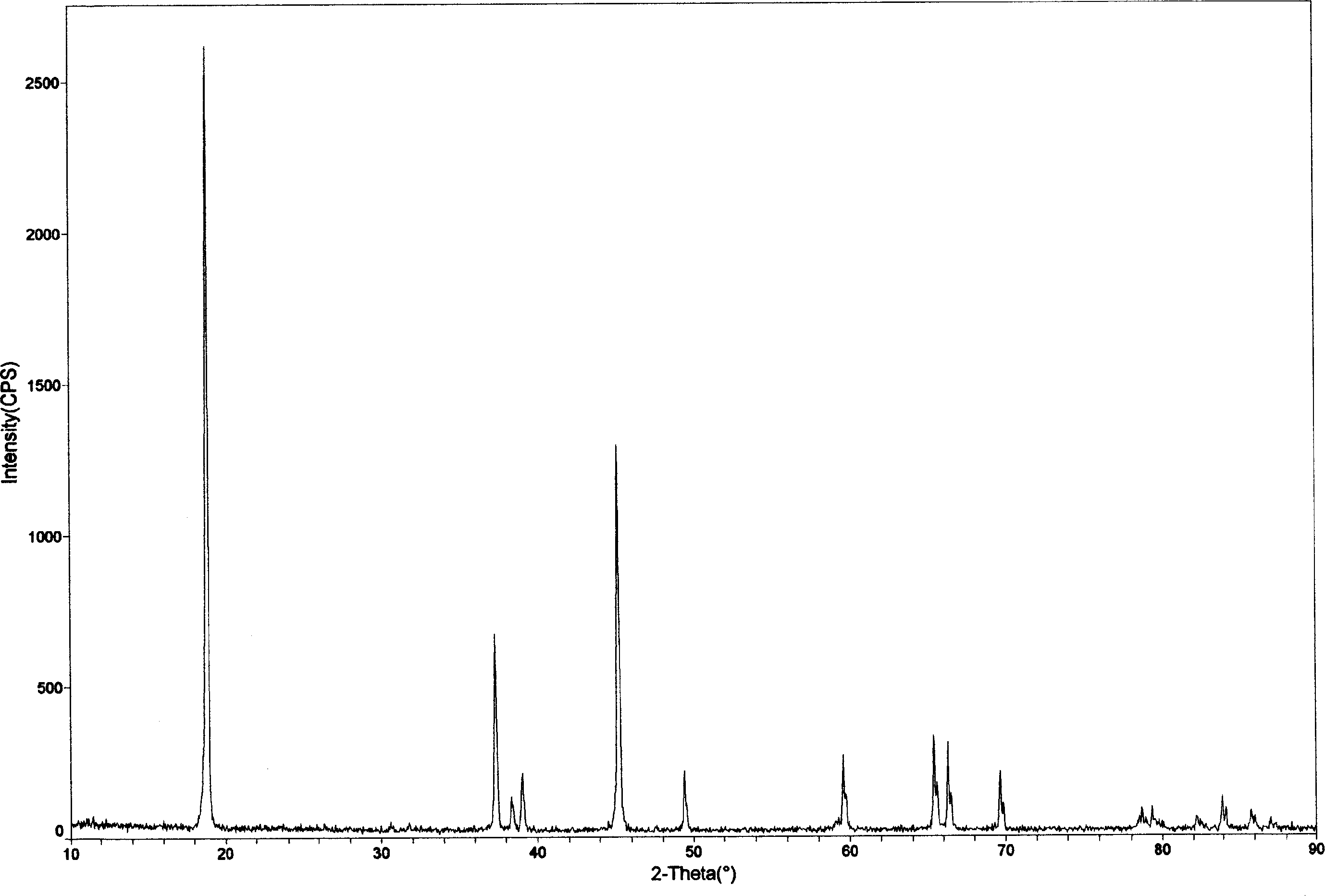

Embodiment 1

[0084] The cobalt block with a content of 99.7% is used as the anode, produced by Jinchuan Nonferrous Metallurgy Co., Ltd., the cathode is made of high-quality stainless steel, the brand is 310S, produced in Switzerland, and the AR absolute alcohol solution of AR lithium bromide is used as the electrolyte. Inter-voltage 5.5V, current density 1.0A / cm 2 . The area of the cobalt block immersed in the electrolyte is 2.5cm 2 , after electrolysis for 100 minutes, an electrolyte solution containing 10.6 grams of cobalt ethoxide was obtained. 30 ml of battery-grade LiOH and AR polyethylene glycol, a mixed aqueous solution with a degree of polymerization of 1000, containing 2.9 grams of anhydrous lithium hydroxide and 10 grams of polyethylene glycol, were added dropwise to the solution containing For the electrolyte of cobalt alcohol, put the sol separated from the centrifuge model TGL-16C, manufactured by Shanghai Anting Scientific Instrument Factory, into a corundum crucible, and...

Embodiment 2

[0085] The cobalt block with a content of 99.7% is used as the anode, produced by Jinchuan Nonferrous Metallurgy Co., Ltd., the cathode is made of high-quality stainless steel, the brand is 310S, produced in Switzerland, the AR absolute ethanol solution of AR sodium bromide is used as the electrolyte, and the dosage is 100.0ml, which contains 2.0 grams of NaBr , inter-electrode voltage 6.5V, current density 1.0A / cm 2 . The area of the cobalt block immersed in the electrolyte is 2.5cm 2, after electrolysis for 100 min, an electrolyte solution containing 10.6 g of cobalt ethoxide was obtained. 30.0 ml of battery-grade LiOH and AR polyethylene glycol, a mixed aqueous solution with a degree of polymerization of 1000, containing 2.9 grams of anhydrous lithium hydroxide and 10.0 grams of polyethylene glycol, were added dropwise to ethanol with stirring For the cobalt electrolyte, put the sol separated from the centrifuge model TGL-16C, manufactured by Shanghai Anting Scientific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com