Method for preparing aragonite type calcium carbonate whisker

A calcium carbonate whisker, aragonite type technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, single crystal growth, etc. Whisker, long total reaction time and other problems, to achieve the effect of large whisker aspect ratio, increase single preparation yield, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

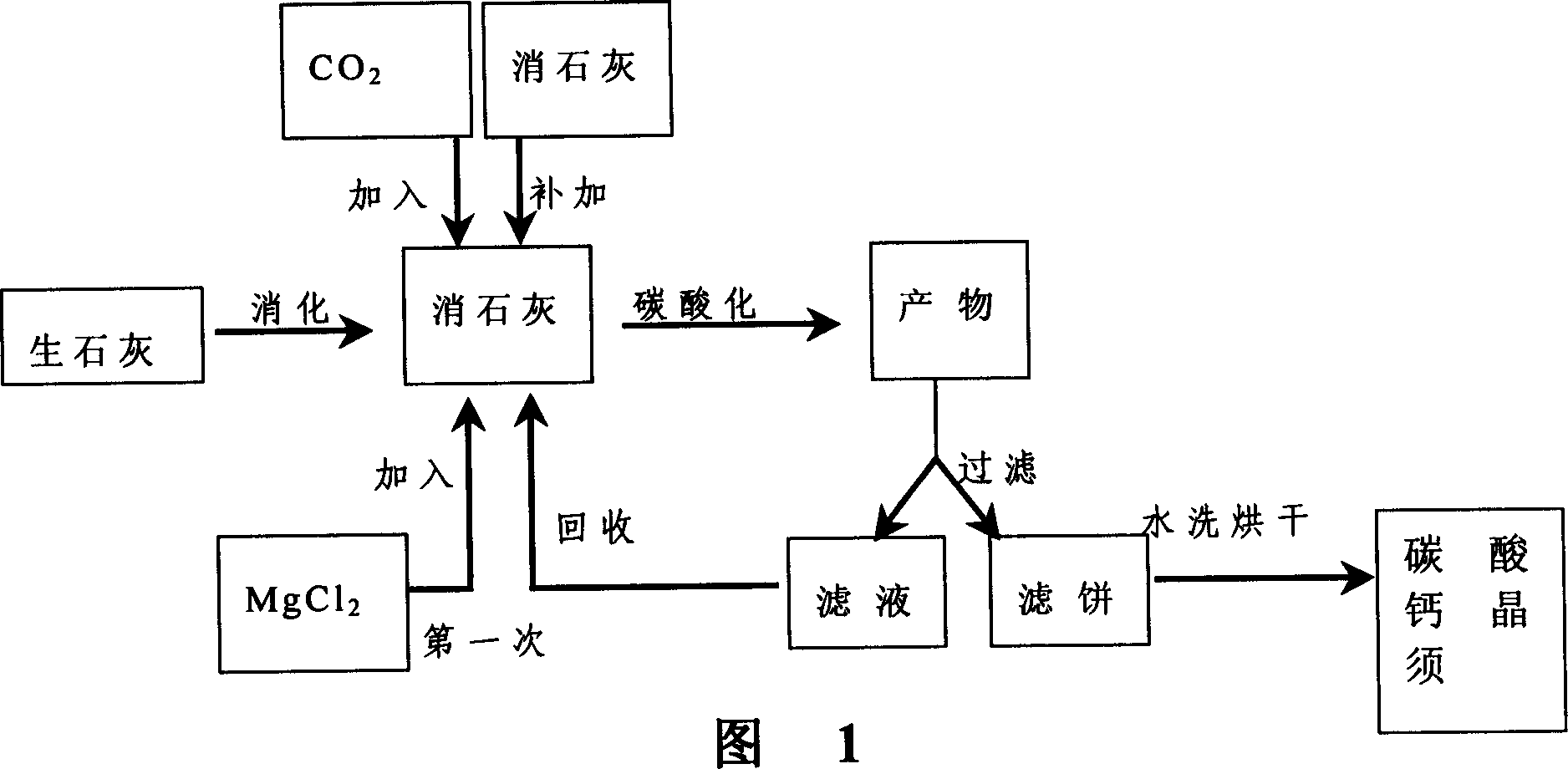

Method used

Image

Examples

reference example 1

[0037] Take industrial slaked lime, add 15 times of water at room temperature and stir at high speed for 0.5 hours to form a slurry. The slurry is subjected to sedimentation and classification to remove coarse particles at the bottom to obtain a refined raw material slurry. The slurry particles are uniform and fine, and there are no coarse particles that can be observed by the naked eye. The slurry concentration was determined to be 26.6g / 100g.

[0038] Put 0.4L of water in a 0.5L three-necked flask, then add 50.8g of magnesium chloride hexahydrate and stir to dissolve it, then add 43.6g of calcium hydroxide slurry into the magnesium chloride solution, and then add about 0.07L of water to rinse into the bottle. Heating while stirring, after 0.5 hours of heat preservation at 80°C, the system becomes a viscous suspension, and CO is injected at 100mL / min 2 Gas, control the carbonation reaction temperature to 80°C, the stirring rate to 250rmp, the pH value at the initial stage of ...

reference example 2

[0040] Take industrial quicklime, add an appropriate amount of water to dry digest it into calcium hydroxide, sieve to remove the coarse impurities, add 20 times of water and stir vigorously to form a rough calcium hydroxide slurry, and remove the coarse particles after three sedimentation classifications, Obtain refined calcium hydroxide slurry, the slurry concentration is 32.4%

[0041] Get the filtrate after filtering in reference example 1, adopt chemical titration to measure Mg 2+ The concentration is 0.48M. Add 2.0g of magnesium chloride hexahydrate to the 0.4L filtrate and place it in a 0.5L three-necked flask. Stir and add 35.7g of refined slurry, then add about 0.08L of water, and heat while stirring. ℃ heat preservation reaction 0.5 hours into CO 2 The carbonation reaction of the gas is carried out, the reaction temperature is controlled at 80°C, and the CO 2 The gas feeding rate was 100 mL / min, and the stirring rate was 200 rpm. Stop the reaction when the pH valu...

Embodiment 1

[0043] Get the same refined calcium hydroxide slurry and reclaimed filtrate in Reference Example 2 as raw materials, get 0.4L filtrate and add magnesium chloride hexahydrate 2.0g and place it in a 0.5L three-necked flask, stir and add 35.8g of refined slurry, and then Add about 0.08L of water, heat while stirring, keep the reaction at 80°C for 0.5 hours and pass CO 2 The carbonation reaction of the gas is carried out, the reaction temperature is controlled at 80°C, and the CO 2 The gas feeding rate was 100 mL / min, and the stirring rate was 250 rpm. The pH value of the suspension at the initial stage of the reaction was 8.05, and the pH value of the system was 7.96 after 2 hours of reaction. Take 35.8 g of the refined slurry and add it evenly at a rate of about 8.9 g / hour, and continue to react until the pH value of the system drops to 6.86. Stop the reaction. After the product is filtered, the filtrate is used for the next reaction. The filter cake is washed with water for 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com