Method for removing high concentration phosphor pollution in alkali wastewater

A phosphorus pollution, high concentration technology, applied in the direction of chemical instruments and methods, water/sewage multi-stage treatment, adsorption water/sewage treatment, etc., can solve the problems that are not conducive to the application of calcite to remove phosphorus, and achieve good application prospects and operation The effect of convenience and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The adsorption experiment was carried out at room temperature (25°C), and the NaH 2 PO 4 The stock solution was dissolved in 0.01M NaCl solution, and the amount of adsorbent was 5 g / L, so that the initial concentration of P in the solution was set at 16.13mM; then a series of 50ml centrifuge tube water samples were placed on the rotary mixer, and the reaction equilibrium time for 7 hours, and then placed in a centrifuge at 4000r / min for 10 minutes, the supernatant was taken, and the concentration of P in the water sample was analyzed by an ultraviolet spectrophotometer.

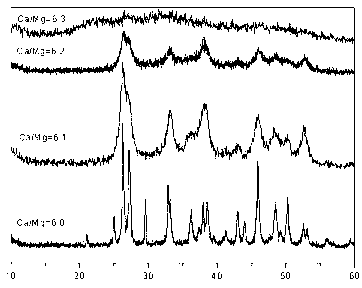

[0049] Such as figure 1 As shown, it shows the XRD characterization of aragonitic calcium carbonate synthesized according to different ratios of calcium and magnesium. The characteristics of calcium carbonate type, the XRD characterization diagram of the adsorbent with a Ca / Mg ratio of 6:2 shows that the characteristics of aragonitic calcium carbonate have become less obvious, and the XRD of the adso...

Embodiment 2

[0052] The adsorption isotherm experiment was carried out at room temperature (25°C), pH=10.0±0.3, by the adsorption experiment method, and the NaH 2 PO 4 The stock solution was dissolved in 0.01M NaCl solution, and the amount of adsorbent was 5 g / L, so that the initial concentration of P in the solution was set at 0-16.13mM; then a series of 50ml centrifuge tube water samples were placed on the rotary mixer, The reaction equilibrium time is 7 hours, and then placed in a 4000r / min centrifuge for 10 minutes, the supernatant is taken, and the concentration of P in the water sample is analyzed by an ultraviolet spectrophotometer.

[0053] Figure 4 Shown is the maximum adsorption capacity of phosphate in water by comparing the adsorbent doped with magnesium (Ca / Mg ratio of 6:2) and the adsorbent without magnesium doped through adsorption experiments. Through the simulation analysis of the experimental results, the adsorption isotherm of phosphorus by the adsorbent without dopin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com