Method for synthesizing aragonite nanorod under conditions of normal pressure and temperature

A technology for synthesizing aragonite and nanorods, applied in nanotechnology, calcium carbonate/strontium/barium and other directions, can solve the problem of high energy consumption, and achieve the effects of easy availability of raw materials, mild reaction conditions and less energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

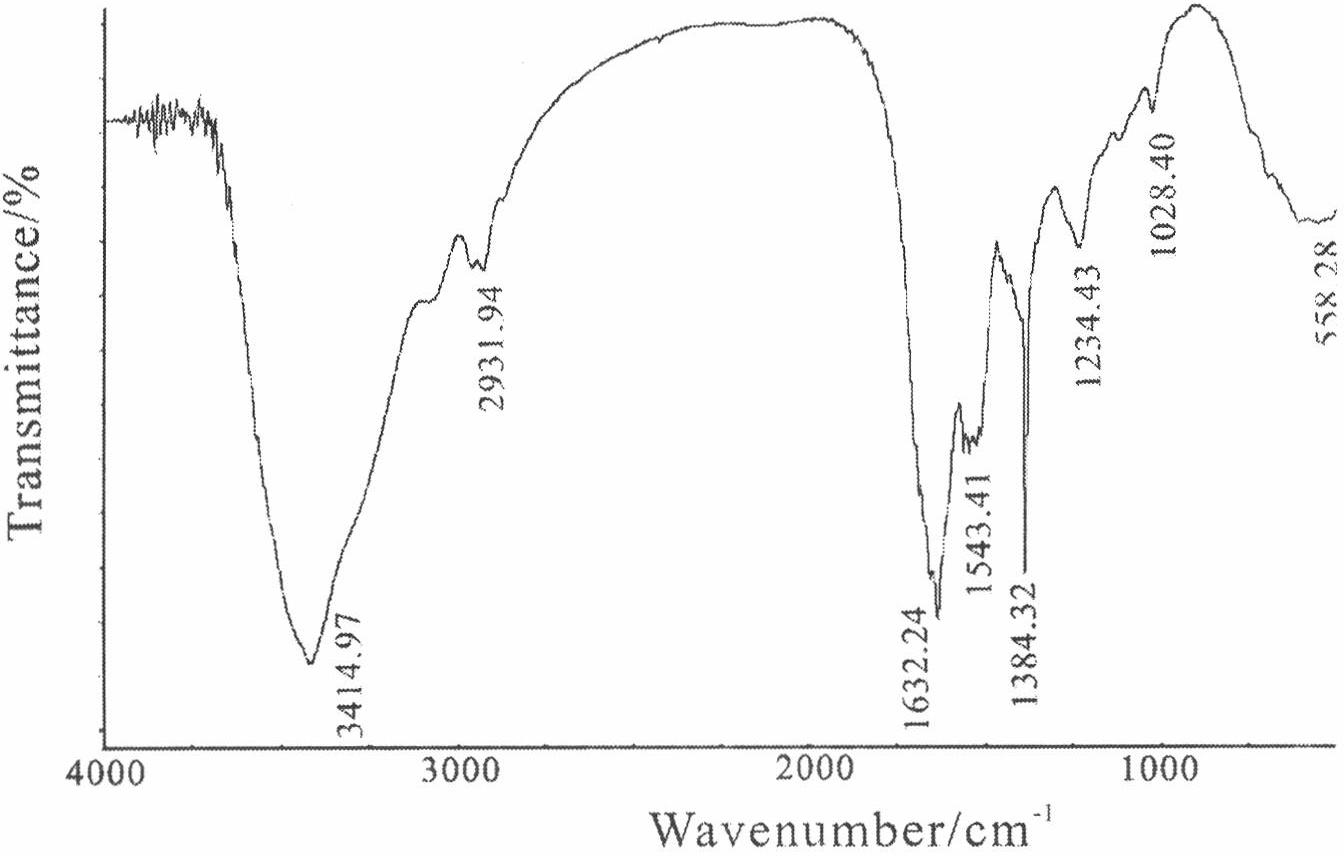

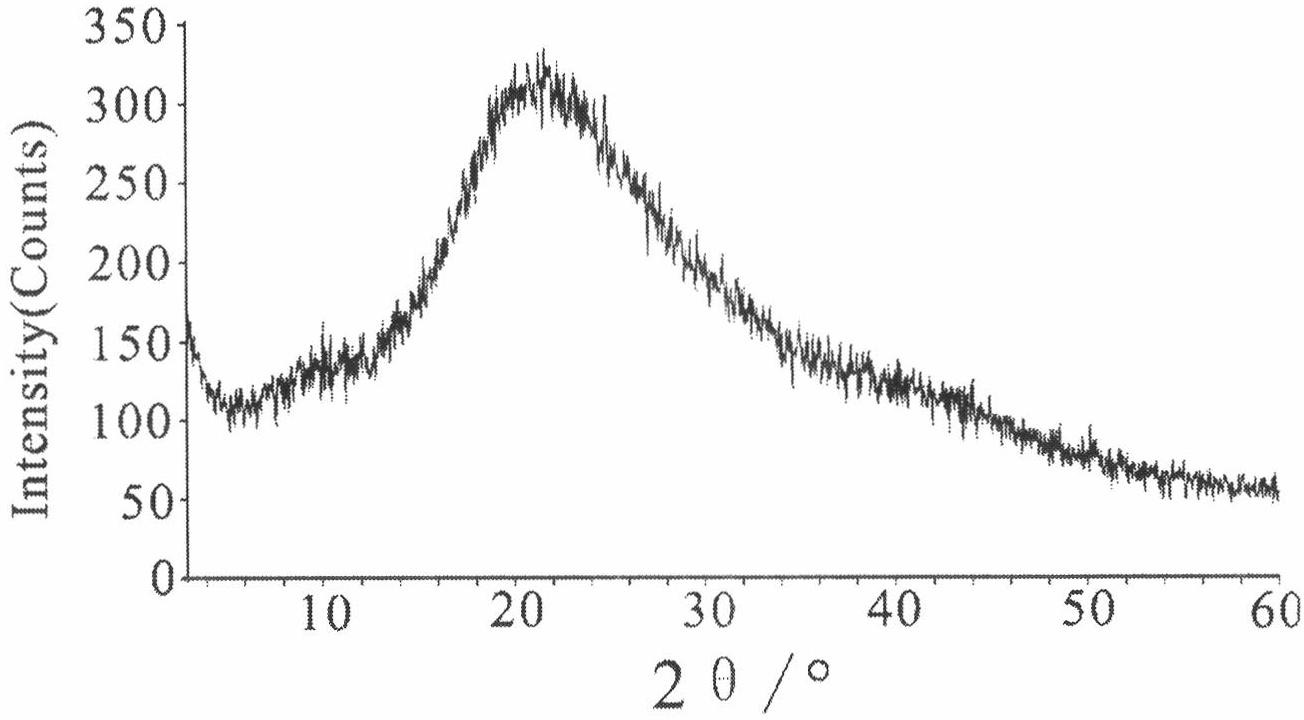

[0054] Prepare 45mmol / L calcium chloride solution and 0.1mol / L dilute sulfuric acid solution, weigh 19.0g of ammonium bicarbonate powder and put it into a watch glass, place the fibrous protein layer of razor clam ligament and the cover glass respectively on the With 10mm CaCl 2 Pour 40mL of dilute sulfuric acid solution into a small beaker, then put them together in a desiccator at 30°C, react for 12 hours, take out the protein layer and cover glass, wash them, and dry them at 37°C Let dry for 12 hours. The obtained white powder was subjected to FTIR test respectively. like Image 6 As shown, A is the infrared spectrum of the sample prepared with the protein layer as the substrate, and B is the infrared spectrum of the product prepared with the cover glass substrate. Among them, A shows the characteristic absorption peaks of calcite (876.31cm-1 and 712.92cm-1), as well as the characteristic absorption peaks of aragonite (855.72cm-1 and 712.92cm-1), and the content of calci...

Embodiment 2

[0056] Configure 9.0mmol / L calcium chloride solution and 0.1mol / L dilute sulfuric acid solution, weigh 19.0g of ammonium bicarbonate powder and put it in a watch glass, place the fibrous protein layer of razor clam ligament and the cover glass on the Filled with 10mm CaCl 2 Pour 40mL of dilute sulfuric acid solution into a small beaker, then put them together in a desiccator at 30°C, react for 12 hours, take out the protein layer and cover glass, wash them, and dry them at 37°C Let dry for 12 hours. The obtained white powder was subjected to FTIR test respectively. like Figure 7 As shown, A is the infrared spectrum of the sample prepared with the protein layer as the substrate, and B is the infrared spectrum of the product prepared with the cover glass substrate. Among them, A shows the characteristic absorption peak of aragonite (855.90cm -1 and 713.22cm -1 ), and it is pure aragonite; B shows the characteristic absorption peak of calcite (876.01cm -1 and 712.43cm -1 ...

Embodiment 3

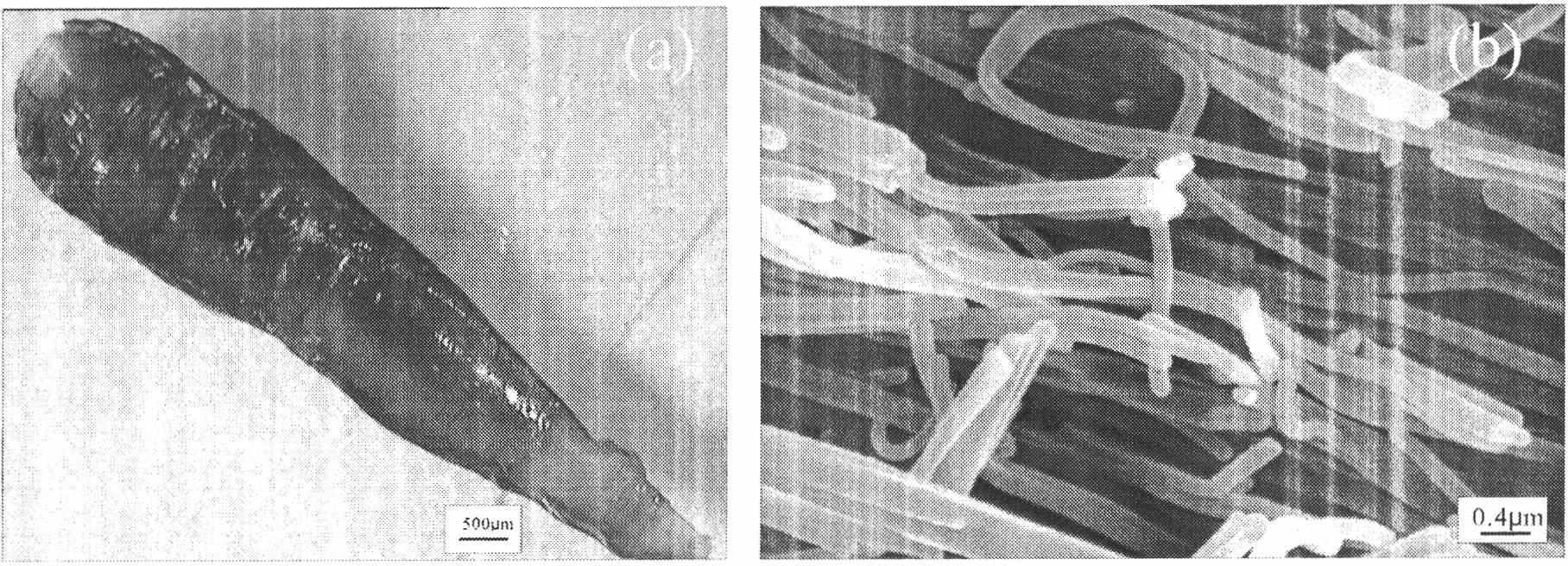

[0058] Prepare 4.5mmol / L calcium chloride solution, 0.1mol / L dilute sulfuric acid solution, weigh 19.0g ammonium bicarbonate powder and put it in a watch glass, place the protein layer and coverslip respectively in 10mm CaCl 2 Pour 40mL of dilute sulfuric acid solution into a small beaker, then put them together in a desiccator at 30°C, react for 12 hours, take out the protein layer and cover glass, wash them, and dry them at 37°C 12 hours. The obtained powders were subjected to FTIR tests respectively. like Figure 8 As shown, A is the infrared spectrum of the product prepared on the cover glass substrate, and B is the infrared spectrum of the sample prepared on the basis of the razor clam protein layer. Among them, A contains calcite and aragonite, the calcite content is 76.7% and the aragonite content is 23.3% according to semi-quantitative calculation, and its appearance is as follows Figure 5 As shown, it is mainly diamond-shaped calcite and a small amount of bundle-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com