Coating solution and coated paper coated with the same

A technology of coating liquid and coated paper, which is applied in the field of coated paper and can solve problems such as not knowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 40 parts by mass of the aragonite columnar light calcium carbonate dispersion slurry prepared in the reference example was mixed with a commercially available wet heavy calcium carbonate slurry (“Kabital 90” manufactured by Immigration Corporation, with an average particle size of 1.2 μm) 60 parts by mass were mixed and stirred to obtain a pigment mixed slurry.

[0043] In this slurry, 3 parts by mass of urea phosphorylated starch (manufactured by Nippon Food & Chemical Corporation) and 10 parts by mass of styrene-butadiene latex (manufactured by Nippon Gosei Co., Ltd.) were blended as a pigment binder as a powder anti-powder agent. 1 part by mass of calcium stearate (manufactured by Sunnapko Co., Ltd.) was adjusted to pH 10 using sodium hydroxide (manufactured by Wako Pure Chemical Industries, Ltd.) to obtain a coating liquid with a solid concentration of 63%.

[0044] Use wire rod for coating to press 8g / m per side 2 After the coating liquid prepared in this way is manual...

Embodiment 2

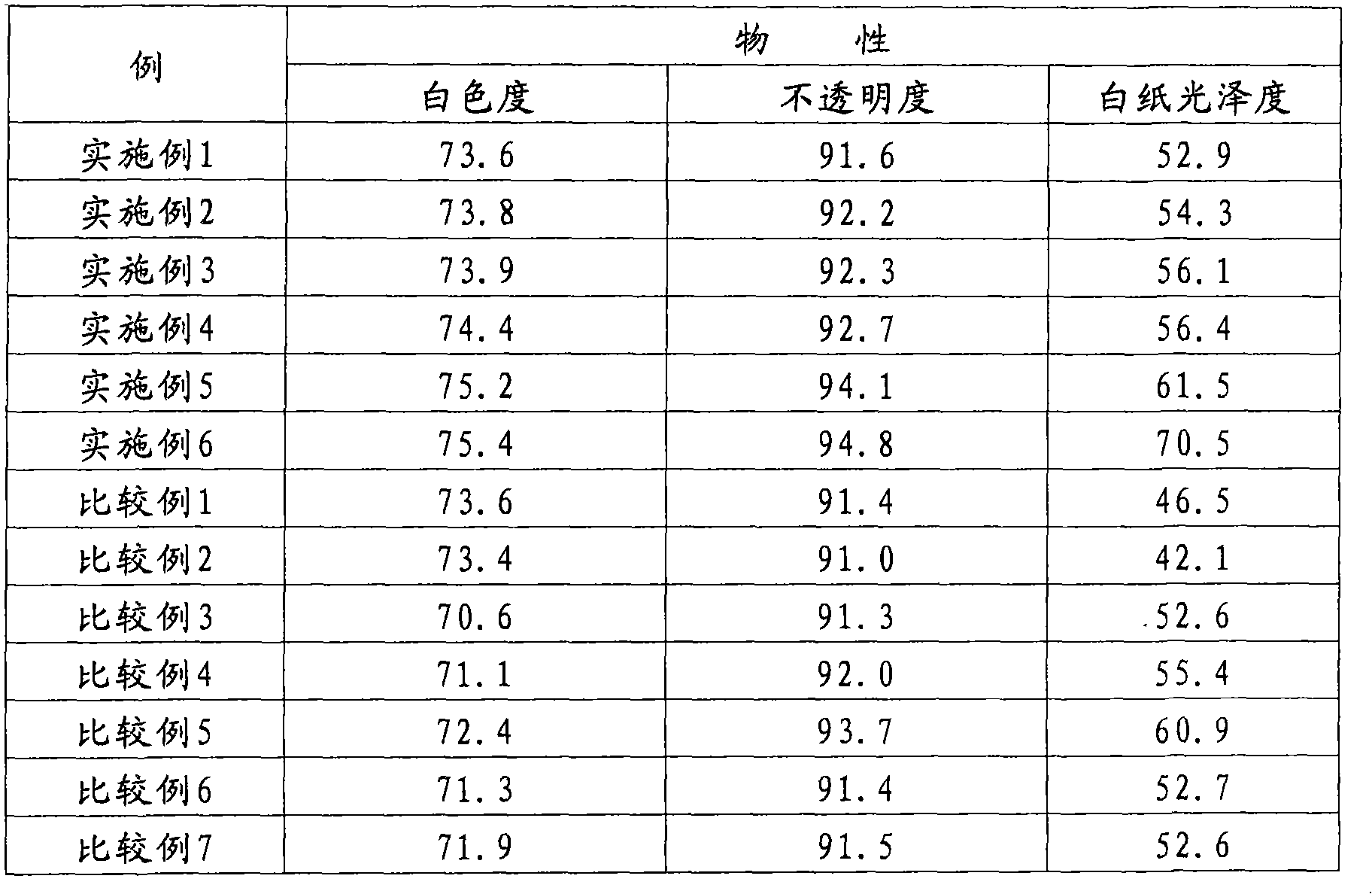

[0046] Except that 60 parts by mass of the light calcium carbonate dispersion slurry prepared in the Reference Example and 40 parts by mass of the wet heavy calcium carbonate were used as the raw material of the pigment mixing slurry, a coating liquid and a coated paper were prepared in the same manner as in Example 1. Table 1 shows the physical properties of the coated paper.

Embodiment 3

[0048] Except for using 80 parts by mass of the light calcium carbonate dispersion slurry prepared in the Reference Example and 20 parts by mass of the wet heavy calcium carbonate, the same procedure as in Example 1 was carried out to prepare a coating liquid and a coated paper. Table 1 shows the physical properties of the coated paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com