Preparation method of Porous aragonite structure micron sheet, ceramic diaphragm and preparation method thereof

A ceramic diaphragm and microchip technology, applied in structural parts, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as poor adhesion, easy agglomeration, and too small contact area between particles, and achieve strong wetting ability, The effect of good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Aiming at the characteristics of nacre and the characteristics of lithium-ion battery separators in the prior art, the present invention provides a method for preparing a porous aragonite micro-sheet. The porous aragonite-structure micro-sheet prepared by the method is actually a two-dimensional porous The calcium carbonate structure micro-sheet is used to prepare a diaphragm, which can make the diaphragm have better lithium ion conductivity, mechanical properties, wettability and mechanical properties. Specifically, the embodiment of the present invention discloses a method for preparing a porous aragonite microsheet, which includes the following steps:

[0031] A) treating the shell shell in an acid solution to obtain the shell shell nacre with an aragonite structure;

[0032] B) processing the shell shell nacre to obtain nacre fragments;

[0033] C) Treating the nacre fragments in an alkaline solution to obtain porous aragonite micro-sheets.

[0034] In the process...

Embodiment 1

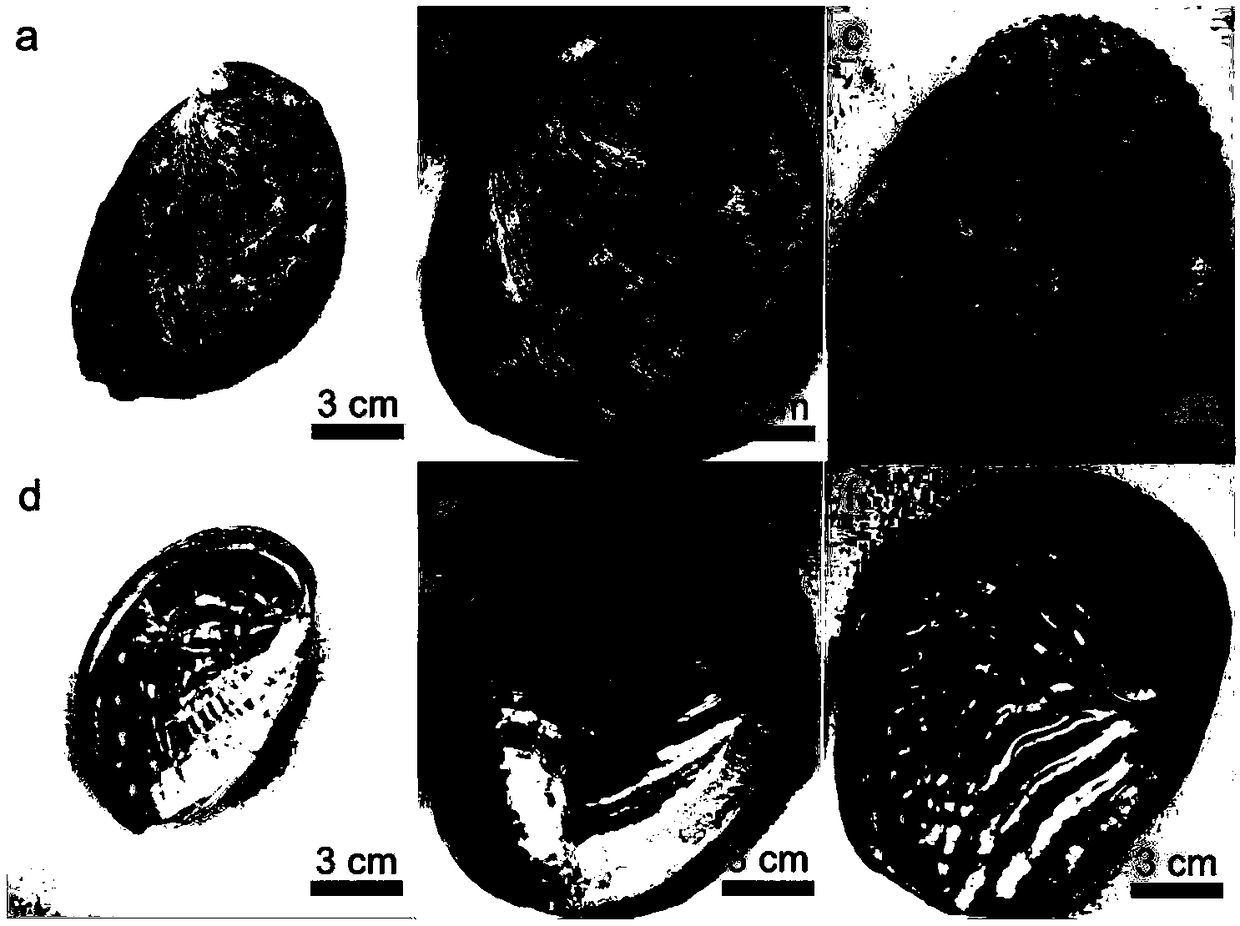

[0046] Take 6.5kg of Korean white abalone shell (the front and back of the abalone shell are shown in the picture figure 1 Shown in a and d) in a 500ml beaker, then pour 10mol / L hydrochloric acid solution of 3 times the weight ratio, remove cuticle, prism layer, calcium carbonate of non-aragonite structure in the abalone shell at room temperature Outer verrucous and algae pigment impurities, a large amount of gas will be generated in the solution. When almost no bubbles are generated in the solution, take out the nacre of the abalone shell and wash off the acid solution on the surface of the nacre with deionized water, and put it in a 60°C oven After medium drying, the pure nacre with aragonite structure is obtained; then the abalone shell nacre is sandwiched between the polytetrafluoroethylene plates and placed on a press and loaded with a pressure of 10Mpa to crush the nacre;

[0047] Take 5g of nacre fragments and add them to a plastic beaker filled with 150mL NaOH solution...

Embodiment 2

[0050] Take 12.5kg of Australian green-lip abalone shell (the front and back of the abalone shell are shown in the picture figure 1 middle b and e) are placed in a 500mL beaker, and then poured into 6 times the weight ratio of 9mol / L nitric acid solution to remove the cuticle, prism layer, non-aragonite calcium carbonate, and outer warts in the abalone shell A large amount of gas will be generated in the solution; when there are almost no bubbles in the solution, take out the abalone shell nacre and wash off the acid solution on the surface of the nacre with deionized water, and dry it in an oven at 70°C Obtain pure nacre with aragonite structure; then sandwich the abalone shell nacre between polytetrafluoroethylene plates and place it on a press and load the pressure of 15Mpa to crush the nacre;

[0051] Take 5g of nacre fragments and add them to a plastic beaker filled with 150mL NaOH solution (3mol / L), use a mechanical stirring paddle to stir the above solution for 4 days, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com