Preparation method of enhanced multiphase crystal based on calcite and aragonite

A calcite and enhanced technology, which is applied in the field of preparation of enhanced multi-phase crystals, can solve the problems of high cost of calcium carbonate powder preparation, complex synthesis process, and process complexity, and achieve low preparation cost, simple synthesis process, and mass production. The effect of the sonization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

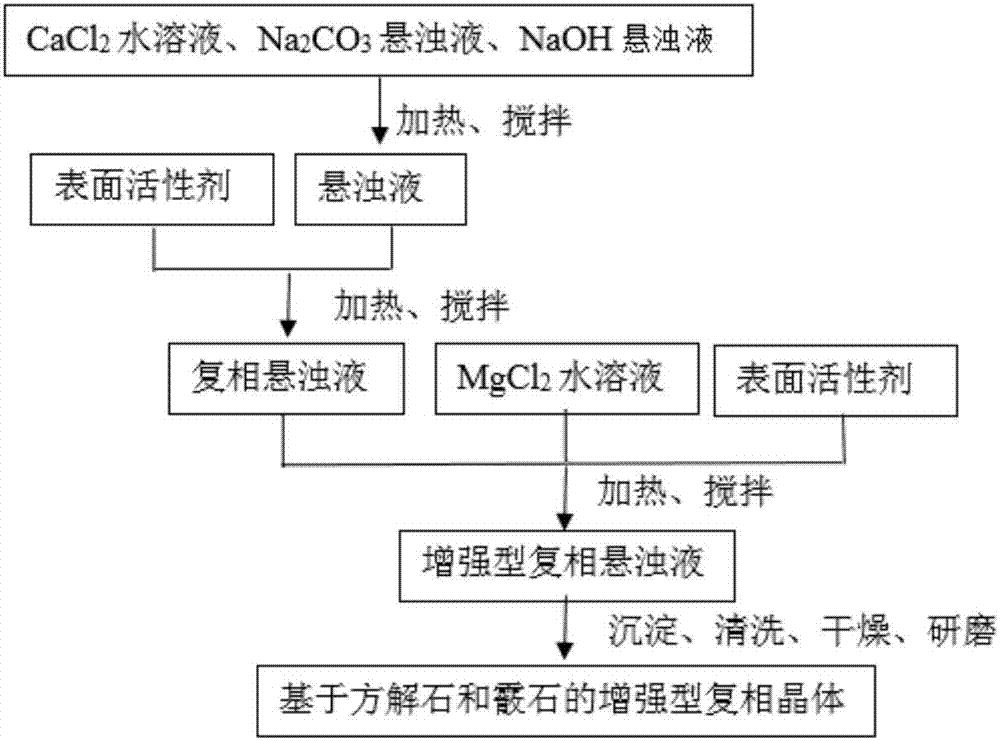

Method used

Image

Examples

Embodiment 1

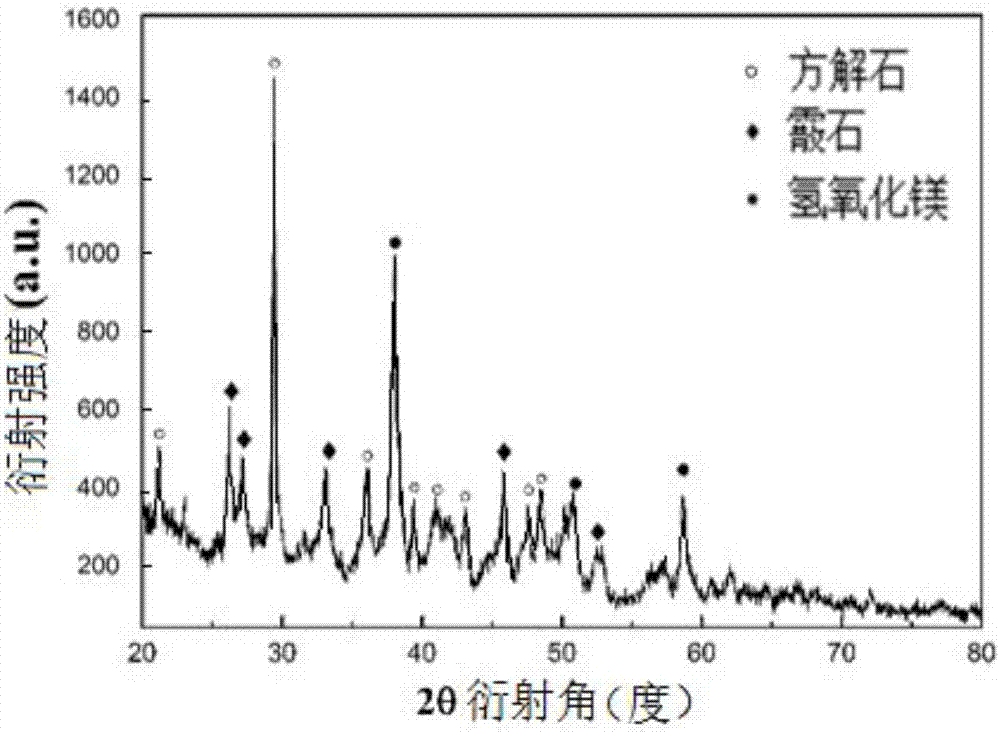

[0042] Embodiment 1: Prepare the enhanced multi-phase crystal based on calcite and aragonite containing 47.2% calcite type calcium carbonate, 20.1% aragonite type calcium carbonate, 32.7% magnesium hydroxide.

[0043] Step 1, prepare CaCl 2 aqueous solution.

[0044] 32.19g of CaCl 2 Dissolve in 500mL deionized water, stir for 15min, and prepare CaCl with a concentration of 0.58mol / L 2 aqueous solution, and filtered to remove impurities.

[0045] Step 2, prepare MgCl 2 aqueous solution.

[0046] 30.94g of MgCl 2 Dissolve in 500mL deionized water, stir for 15min, and prepare MgCl with a concentration of 0.65mol / L 2 aqueous solution, and filtered to remove impurities.

[0047] Step 3, prepare Na 2 CO 3 Suspension.

[0048] 24.38g of Na 2 CO 3 Dissolve in 500mL deionized water, stir for 15min, and prepare Na with a concentration of 0.46mol / L 2 CO 3 suspension, and filtered to remove impurities.

[0049] Step 4, prepare NaOH suspension.

[0050] Dissolve 37g of NaO...

Embodiment 2

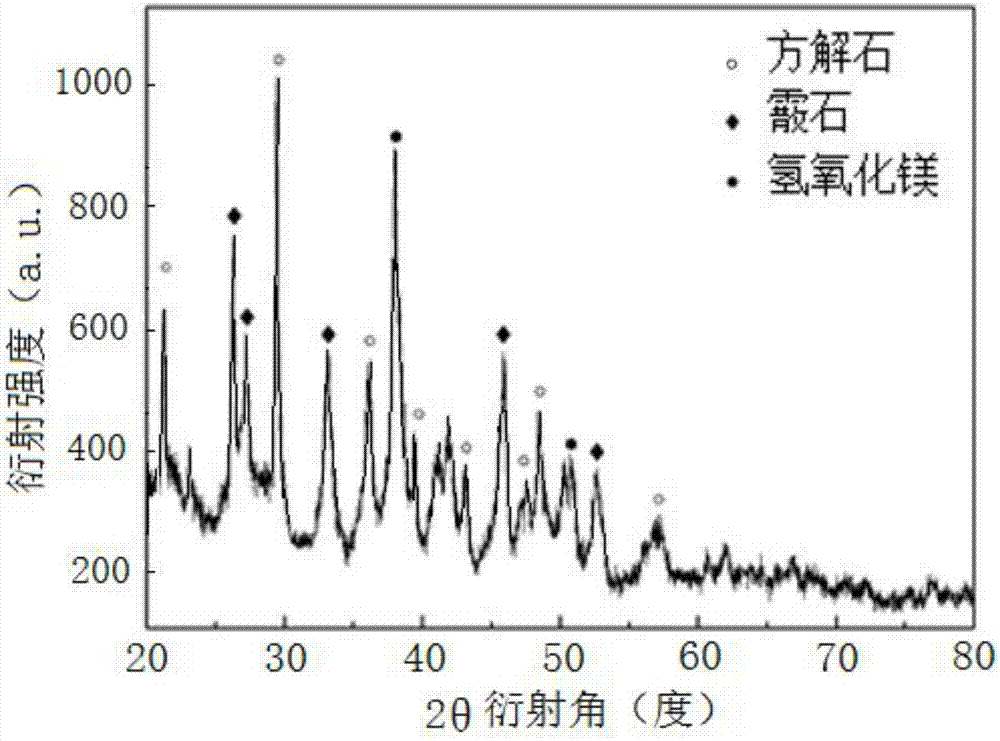

[0060] Embodiment 2: Prepare the enhanced multi-phase crystal based on calcite and aragonite containing 38.4% calcite type calcium carbonate, 27.9% aragonite type calcium carbonate, 33.7% magnesium hydroxide.

[0061] Step 1, prepare CaCl 2 aqueous solution.

[0062] 75.78g of CaCl 2 Dissolve in 500mL deionized water, stir for 15min, and prepare CaCl with a concentration of 1.36mol / L 2 aqueous solution, and filtered to remove impurities.

[0063] Step two, prepare MgCl 2 aqueous solution.

[0064] 54.75g of MgCl 2 Dissolve in 500mL deionized water, stir for 15min, and prepare MgCl with a concentration of 1.15mol / L 2 aqueous solution, and filtered to remove impurities.

[0065] Step three, prepare Na 2 CO 3 Suspension.

[0066] 50.88g of Na 2 CO 3 Dissolve in 500mL deionized water, stir for 15min, and prepare Na with a concentration of 0.96mol / L 2 CO 3 suspension, and filtered to remove impurities.

[0067] Step 4, prepare NaOH suspension.

[0068] Dissolve 63.4...

Embodiment 3

[0078] Example 3: Preparation of an enhanced multiphase crystal based on calcite and aragonite containing 40.4% calcite-type calcium carbonate, 30.9% aragonite-type calcium carbonate, and 28.7% magnesium hydroxide.

[0079] Step A, preparation of CaCl 2 aqueous solution.

[0080] 119.325g of CaCl 2 Dissolve in 500mL deionized water, stir for 15min, and prepare CaCl with a concentration of 2.15mol / L 2 aqueous solution, and filtered to remove impurities.

[0081] Step B, preparation of MgCl 2 aqueous solution.

[0082] 83.78g of MgCl 2 Dissolve in 500mL deionized water, stir for 15min, and prepare MgCl with a concentration of 1.76mol / L 2 aqueous solution, and filtered to remove impurities.

[0083] Step C, prepare Na 2 CO 3 Suspension.

[0084] 67.84g of Na 2 CO 3 Dissolve in 500mL deionized water, stir for 15min, and prepare Na with a concentration of 1.28mol / L 2 CO 3 suspension, and filtered to remove impurities.

[0085] Step D, prepare NaOH suspension.

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com