Environmental interior wall putty powder

An interior wall putty powder, environmentally friendly technology, applied in the direction of filling slurry, etc., can solve the problems of serious harm to infants, nervous system damage, carcinogenicity, etc., and achieves strong waterproofness, high bonding strength, and good crack resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

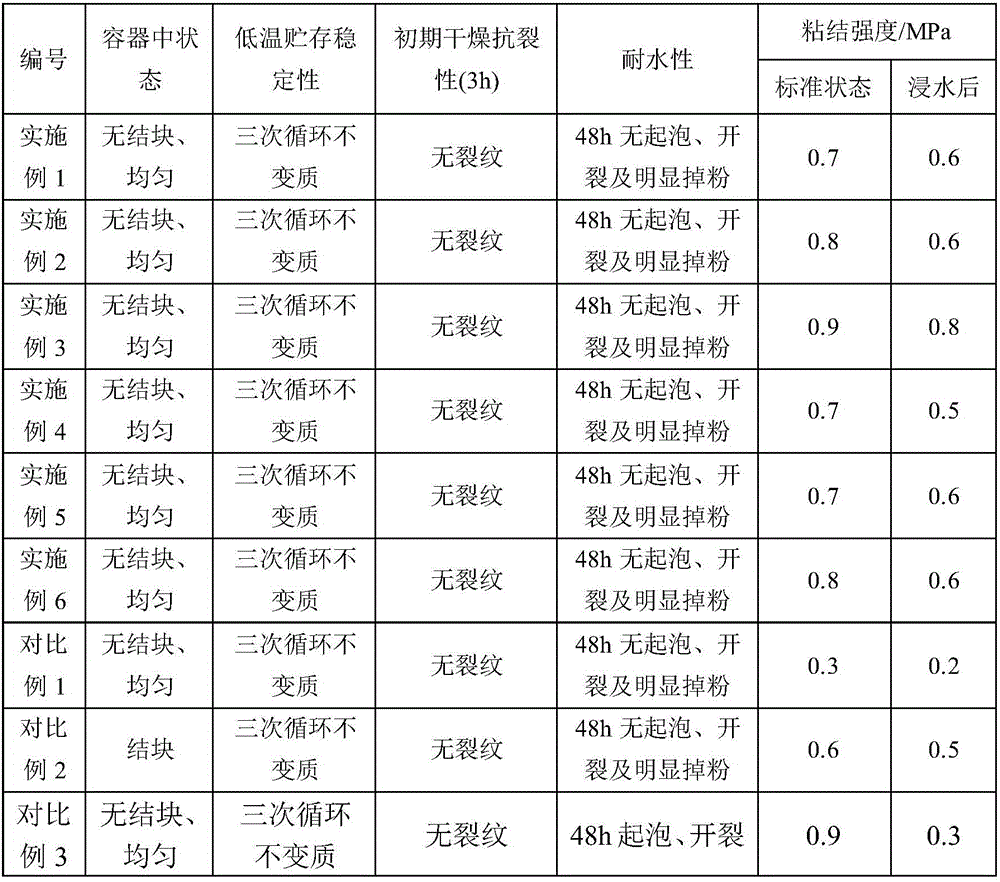

Examples

Embodiment 1

[0045] An environmentally friendly interior wall putty powder, composed of the following weight percentages: white cement 25%, mineral powder 10%, aragonite powder 10%, porous absorbent material 5%, dispersible latex powder 1.5%, binder 1% , Magnesium lithium silicate 1%, water retention agent 0.2%, anion powder 2%, antiseptic and antifungal agent 0.05%, surfactant 0.2%, antibacterial agent 1%, defoamer 0.02%, water repellent 0.001%, balance It is quartz sand powder.

[0046] The whiteness of the white cement is not less than 87, and the strength grade is 42.5.

[0047] The mineral powder is S95 grade mineral powder.

[0048] The fineness of the aragonite powder is greater than 500 mesh, and the whiteness is not less than 90.

[0049] The porous adsorbent refers to sodium bentonite, and the fineness is above 400 mesh.

[0050] The binder refers to guar hydroxypropyltrimethylammonium chloride.

[0051] The water retaining agent refers to xanthan gum.

[0052] The negative ion powder is c...

Embodiment 2

[0061] An environmentally friendly interior wall putty powder, composed of the following weight percentages: white cement 30%, mineral powder 15%, aragonite powder 15%, porous absorbent material 8%, dispersible latex powder 2.2%, binder 5% , Magnesium lithium silicate 3%, water retention agent 1%, anion powder 5%, anti-corrosion and anti-mold agent 0.25%, surfactant 0.8%, antibacterial agent 3%, defoamer 0.1%, water repellent 0.002%, balance It is quartz sand powder.

[0062] The whiteness of the white cement is not less than 87, and the strength grade is 42.5.

[0063] The mineral powder is S95 grade mineral powder.

[0064] The fineness of the aragonite powder is greater than 500 mesh, and the whiteness is not less than 90.

[0065] The porous adsorbent is composed of sodium bentonite and nano-porous silica in a weight ratio of 1:1, wherein the fineness of the sodium bentonite is above 400 mesh.

[0066] The nano-scale porous silica has a porosity of over 90%, a pore diameter of 10n...

Embodiment 3

[0078] An environmentally friendly interior wall putty powder, composed of the following weight percentages: white cement 27%, mineral powder 12%, aragonite powder 14%, porous absorbent material 7%, dispersible latex powder 2%, binder 3% , Magnesium lithium silicate 1.5%, water retention agent 0.8%, anion powder 3%, antiseptic and antifungal agent 0.15%, surface active agent 0.4%, antibacterial agent 2%, defoamer 0.08%, water repellent 0.0015%, balance It is quartz sand powder.

[0079] The whiteness of the white cement is not less than 87, and the strength grade is 42.5.

[0080] The mineral powder is S95 grade mineral powder.

[0081] The fineness of the aragonite powder is greater than 500 mesh, and the whiteness is not less than 90.

[0082] The porous absorbent material is composed of sodium bentonite and nano-porous silica in a mass ratio of 3:1, the fineness of the sodium bentonite is all above 400 mesh, and the nano-porous silica, The porosity is above 90%, the pore diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com