Aragonite-type light calcium composition used in paper coating, and application method thereof

An aragonite type and composition technology, applied in the direction of pigment-containing coatings, etc., can solve the problems of poor quality and unusable papermaking industry, and achieve the effects of improving paper products, improving quality, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Raw materials: 1 ton of Sishui limestone, 65 kg of anthracite from Shanxi, 0.5 kg of mixed seed crystals of magnesium salt and gypsum.

[0031] The synthesis method of aragonite-type light calcium: add anthracite and Surabaya limestone at 6.5%, control the kiln at 930°C, control the calcination time for 3 hours, digest quicklime, and control the digestion concentration to 20%, carbonize the digested slurry, pass into The speed of the purified kiln gas is 1.5 cubic meters per ton of slurry per minute, and 0.5 kg of mixed seed crystals are placed in the carbonization tank. When the pH value of the carbonized slurry is 7, continue to feed the kiln gas for 15 minutes, and the carbonized The light calcium slurry is concentrated by filter cloth pressure filtration, and fully dispersed to a light calcium slurry with a solid content of 65%.

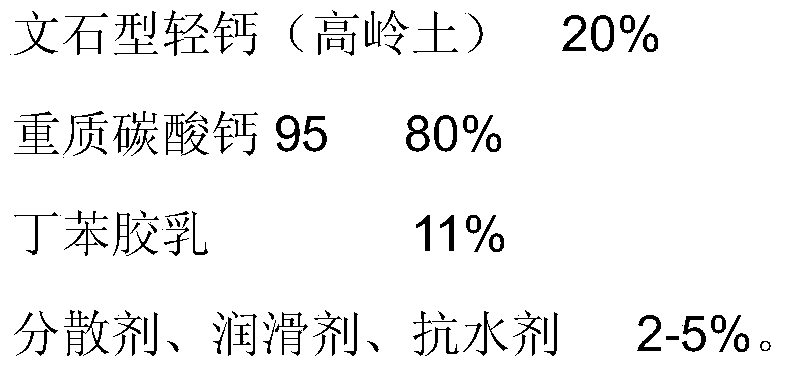

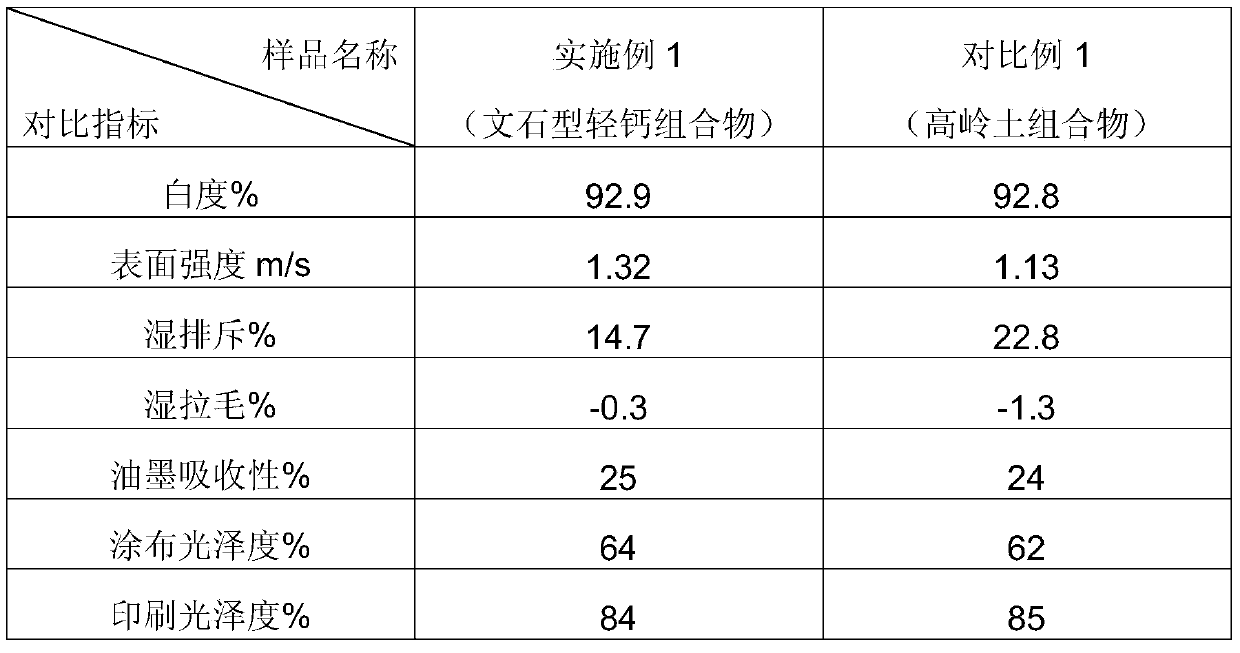

[0032] The application method of the aragonite type light calcium composition (according to the following formula and method, the composi...

Embodiment 2

[0040] Raw materials: 1 ton of Sishui limestone, 100 kg of anthracite from Shanxi, 2 kg of mixed seed crystals of magnesium salt and gypsum.

[0041]Synthesis method of aragonite-type light calcium: Add anthracite and Surabaya limestone at 10%, control the kiln at 1050°C, control the calcination time for 1 hour, digest quicklime, and control the digestion concentration to 33%, carbonize the digested slurry, pass it into The speed of the purified kiln gas is 0.8 cubic / ton of slurry / min, and 2 kg of mixed seed crystals are put into the carbonization tank. When the pH value of the carbonized slurry is 7, continue to feed the kiln gas for 20 minutes, and the carbonized The light calcium slurry is concentrated by filter cloth pressure filtration, and fully dispersed to a light calcium slurry with a solid content of 70%.

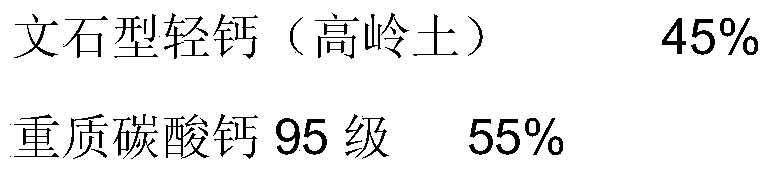

[0042] The application method of aragonite type light calcium (according to the following formula and method, the composition of embodiment 2 and kaolin is detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com